22

ENG

+0300046IE - rel. 1.2 - 14.01.2021

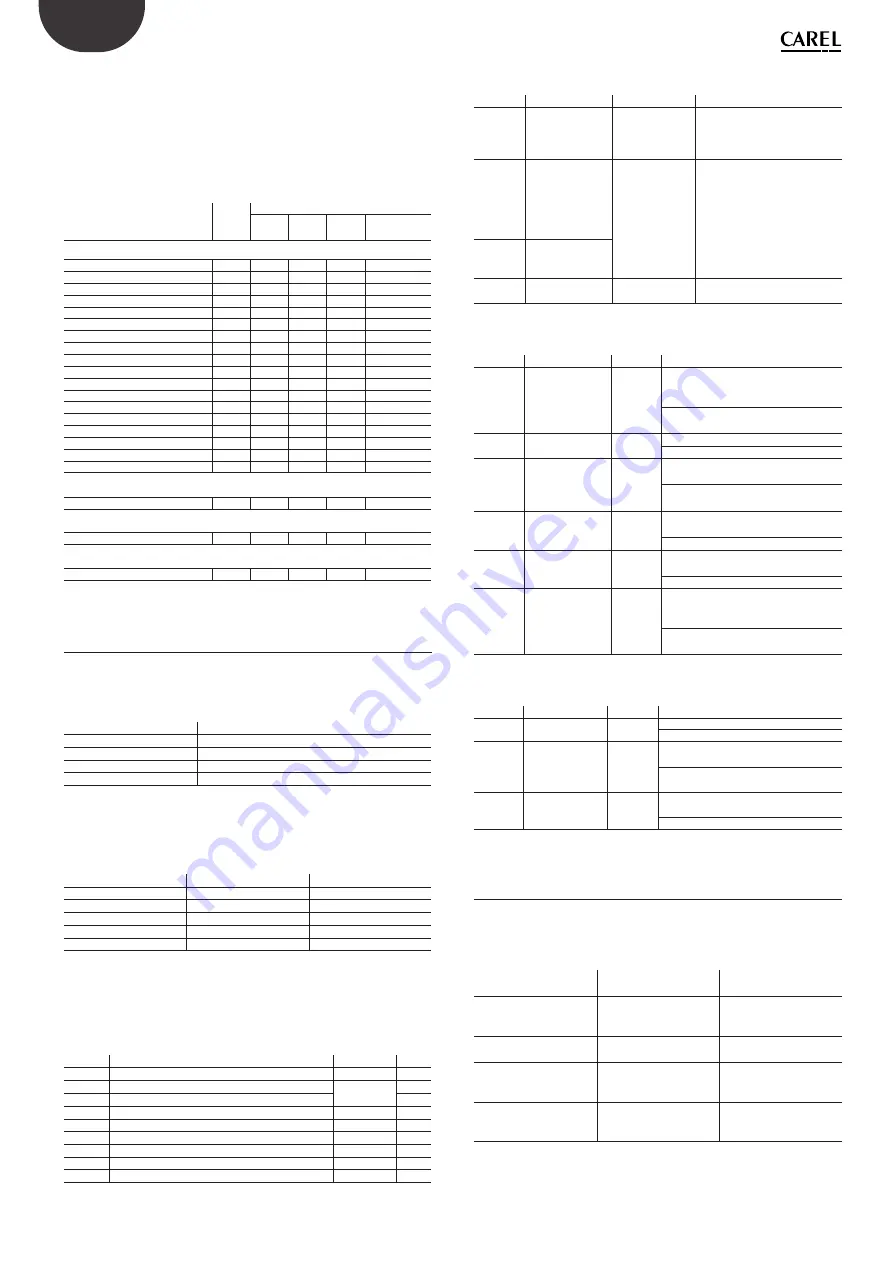

Response time

The response time T50 or T90 (in seconds) is the time taken to reach 50%

or 90% respectively after supplying the target gas at a concentration of

100% of the sensor’s full scale.

T10 is the time needed to return from 100% to 10% of the sensor’s full

scale. Response times are typical values measured under reference

conditions. All response times are expressed in seconds and represent

nominal values.

Type of gas

Range

[ppm]

Average response time [s]

T50

T90

T100

T10

(return)

Semiconductor, refrigerant

HFO1234YF

1000

132

348

544

300

HFO1234ZE

1000

154

429

903

363

R134A

1000

240

597

860

612

R32

1000

72

222

473

200

R404A

1000

104

315

495

248

R407A

1000

94

391

676

420

R407F

1000

114

412

732

366

R410A

1000

67

247

483

217

R448A

1000

95

307

544

233

R449A

1000

110

339

552

291

R450A

1000

158

494

844

462

R452A

1000

98

340

601

268

R452B

1000

86

265

539

281

R454A

1000

98

293

592

251

R507

1000

72

238

486

223

R513A

1000

135

411

659

452

R454B

1000

71

223

595

294

R455A

1000

97

262

598

309

NDIR

CO2

10000

28

140

366

150

Electrochemical

(NH3)

100

22

101

413

97

Semiconductor, flammable

R290

2500

10

22

98

36

Tab. 5.g

5.4 Modbus registers

5.4.1 Modbus connections

The RS485 port allows communication with the gas detector using the

Modbus-RTU protocol.

Connection symbol

Meaning

B

-, Rx, inverting signal

A

+, Tx, non-inverting signal

GND

Earth reference (other than 0 V)

SH

Shielded cable connection

Tab. 5.h

5.4.2 Modbus configuration

The RS485 communication settings can be selected.

Setting

Selection

Default

Address

1 to 247

1

Baud rate

9600 -19200 baud

19200 baud

Stop bits

1-2

2

Parity

None-Odd-Even

None

120 Ω termination

Enable-Disable

Disable

Tab. 5.i

5.4.3 List of variables

04 - Input Registers - R

Register Description

Range

Unit

100

Gas concentration level (% of full scale)

0 : 100

%

101

Gas concentration level in ppm

See the gas

range table

ppm

103

Full scale sensor level in ppm

ppm

104

Low alarm set point (% full scale) (local)

0 : 100

%

105

Sensor timer

0 : 65,535

hours

106

Detector Modbus address

1 : 247

107

Software version (firmware revision)

-

108

Machine code (proprietary machine number)

527

109

Order number

300

Tab. 5.j

03 - Holding Registers - R/W

Register

Description

Range

Details

200

High alarm

set point (ppm)

See the

gas range table

High alarm set point / thresh-

old in parts per million (set

by controller, overwrite local

sensor values)

201

Alarm delay

0 : 15

Buzzer-alarm delay sets the

time (in minutes) that the

buzzer flag and alarm flag are

activated after the gas con-

centration exceeds the alarm

set point.

202

Buzzer delay

(mapped to

register 201)

The values set for reg. 201 and

reg. 202 are always the same

203

Low alarm alarm

set point (ppm)

See the gas range

table

Low alarm set point / threshold

level in parts per million

Tab. 5.k

02 - Input Status - R

Register Description

Range

Details

300

High alarm flag

0 : 1

1: The gas concentration is greater

than or equal to the high alarm set

point

0: The gas concentration is below the

high alarm set point

301

Relay status

0 : 1

1: One or more relays are active.

0: All relays are inactive

302

Sensor fault

0 : 1

1: Sensor not found or sensor open

circuit detected.

0: Sensor found in the circuit and no

open circuit fault detected

303

Red LED

0 : 1

1: The red LED is on. Alarm/fault

indication.

0: The red LED is off.

304

Green LED

0 : 1

1: The green LED is on.

Warm-up status or normal operation.

0: The green LED is off.

307

Low alarm flag

0 : 1

1: The gas concentration is greater

than or equal to the low alarm set

point

0: The gas concentration is below the

low alarm set point

Tab. 5.l

01 - Coils Status - R/W

Register Description

Range

Details

400

Buzzer flag

0 : 1

1: buzzer on

0: buzzer off

401

Test flag

0 : 1

1: Sensor on/operating for more than 1

year and requires testing.

0: The sensor does not yet require

testing.

402

Relay contact

behaviour

0 : 1

1: Fault relay operation (see the relay

logic table)

0: Standard relay operation (default)

Tab. 5.m

4.1 Relay logic table

Relay behaviour with relay failsafe operation (register 402)

0: Standard relay operation (default)

1: Relay failsafe operation

This register value will affect each relay.

Event cause

0: Standard operation

(default)

1: Failsafe operation

At power on

Relays 1, 2, 3 de-ener-

gised:

NO the output is open

Relays 1, 2, 3 energised:

NO the output is closed

Sensor fault active

Relay 3 energised:

NO the output is closed

Relay 3 de-energised:

NO the output is open

If the gas level exceeds

the low alarm threshold

register 203

Relay 2 energised:

NO the output is closed

Relay 2 de-energised:

NO the output is open

If the gas level exceeds

the high alarm threshold

register 200

Relay 1 energised:

NO the output is closed

Relay 1 de-energised:

NO the output is open

Tab. 5.n

Summary of Contents for GDWB

Page 2: ......

Page 4: ...4 ITA 0300046IE rel 1 2 14 01 2021...

Page 6: ......

Page 26: ...26 ITA 0300046IE rel 1 2 14 01 2021 Notes...

Page 28: ...4 ENG 0300046IE rel 1 2 14 01 2021...

Page 30: ......

Page 50: ...26 ENG 0300046IE rel 1 2 14 01 2021 Notes...

Page 51: ......