22

ENG

“Ultrasound for fancoil” +0300059IE - rel. 1.5 - 15.07.2019

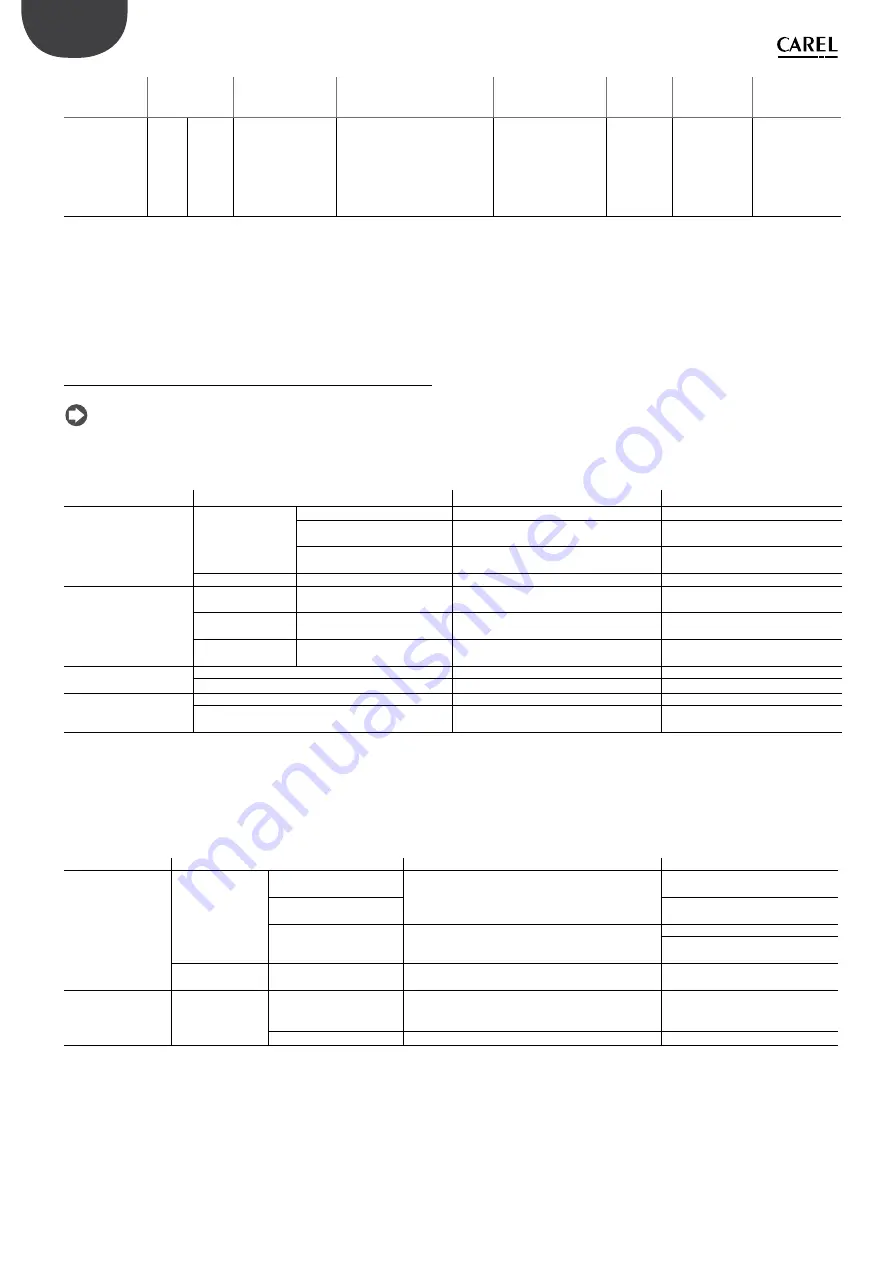

red LED signal

(*)

code and

symbol on di-

splay (fl ashing)

meaning

cause

solution

alarm relay

activation

action

reset

9 fast fl ashes

EtL

End of piezoelectric

transducer life

The unit has reached AF

working hours (default 9999 h)

Replace the

piezoelectric

transducers to

guarantee rated unit

production

yes

signal only

Reset internal

piezoelectric

transducer coun-

ter by setting

parameter d6 to

zero (See chapter

5.8)

Tab. 8.a

To reset the alarms, press ESC once to mute the buzzer, press ESC a

second time to completely reset the alarm.

(*) Fast fl ash: 0.2 seconds ON and 0.2 seconds OFF

Slow fl ash: 1 second ON and 1 second OFF

8.1 Troubleshooting

Note:

if the problem identifi ed cannot be solved using the following

guide, contact CAREL technical service.

1.

Firstly, check the humidifi er and the surrounding area.

Problem

Cause

Check

Solution

No atomised water

production

Power supply

Terminal M14 open

Visual verify

Connetct

terminal M14 to a bridge

No power

Measure the voltage at the humidifi er

input terminals of the transformer

Connect power

Power supply fault

Measure the voltage at the power

supply output terminals

Replace the power supply

Feedwater system

Valve closed upstream

Check

Open the valve

The quantity of atomised

water is too low

Power supply

Low power supply voltage

Check the voltage at the power supply

output terminals

Replace the power supply, if

damaged

Feedwater system

Water level during production

is too high and overfl owing

Check visually

See table 2)

Other

The humidifi er is not installed

horizontally

Check visually

Adjust

No atomised water

production

Dust and foreign matter accumulated in the tank (*)

Clean the inside of the tank

Transducer deterioration

Verify the d6 >0 parameter

Repalce if d6=0

The quantity of atomised

water is too low

Dust and foreign matter accumulated in the tank (*)

Check a view the inside of the tank

Scale build-up on the surface of the piezoelectric

transducers (*)

Clean the inside of the tank

and replace the transducers

Tab. 8.b

(*) These malfunctions can be avoided by carrying out preventive

maintenance.

2.

If the cause has not been identifi ed with the previous checks, there

may be faulty components. Check the inside of the humidifi er.

Problem

Cause

Check

Solution

No atomised water

production

Feedwater system Float level sensor fault

Empty the tank, remove the electronic board

and check continuity of the level sensor

Contact service to replace the level

sensor

Float level sensor blocked

Clean the sensor. If normal opera-

tion is not restored, replace

Fill valve fault

No water fi lled even when the tank has been

emptied

Replace the valve

Clean the sensor. If normal opera-

tion is not restored, replace

Other

The fan cables are loose or

detached

Check connection after removing the

humidifi er cover

Restore correct connection to the

terminals

The quantity of

atomised

water is too low

Water level over-

fl ow

Float level sensor blocked

If the water level in the tank reaches the overfl ow

pipe, remove the connector from the control board

and check continuity of the level sensor

If there is continuity, contact service

to replace the level sensor

Fill valve fault

Water is fi lled even after switching off the appliance Replace the fi ll valve

Tab. 8.c