34

ENG

Maintenance

WTS LARGE +0300131IT rel. 1.0 - 05.09.2022

Before replacing the membrane(s), check the following:

•

The ROL unit is switched off

•

The inlet valve is closed, there is no pressure on the water line.

The steps for membrane replacement are described in detail in the chapter mechanical installation.

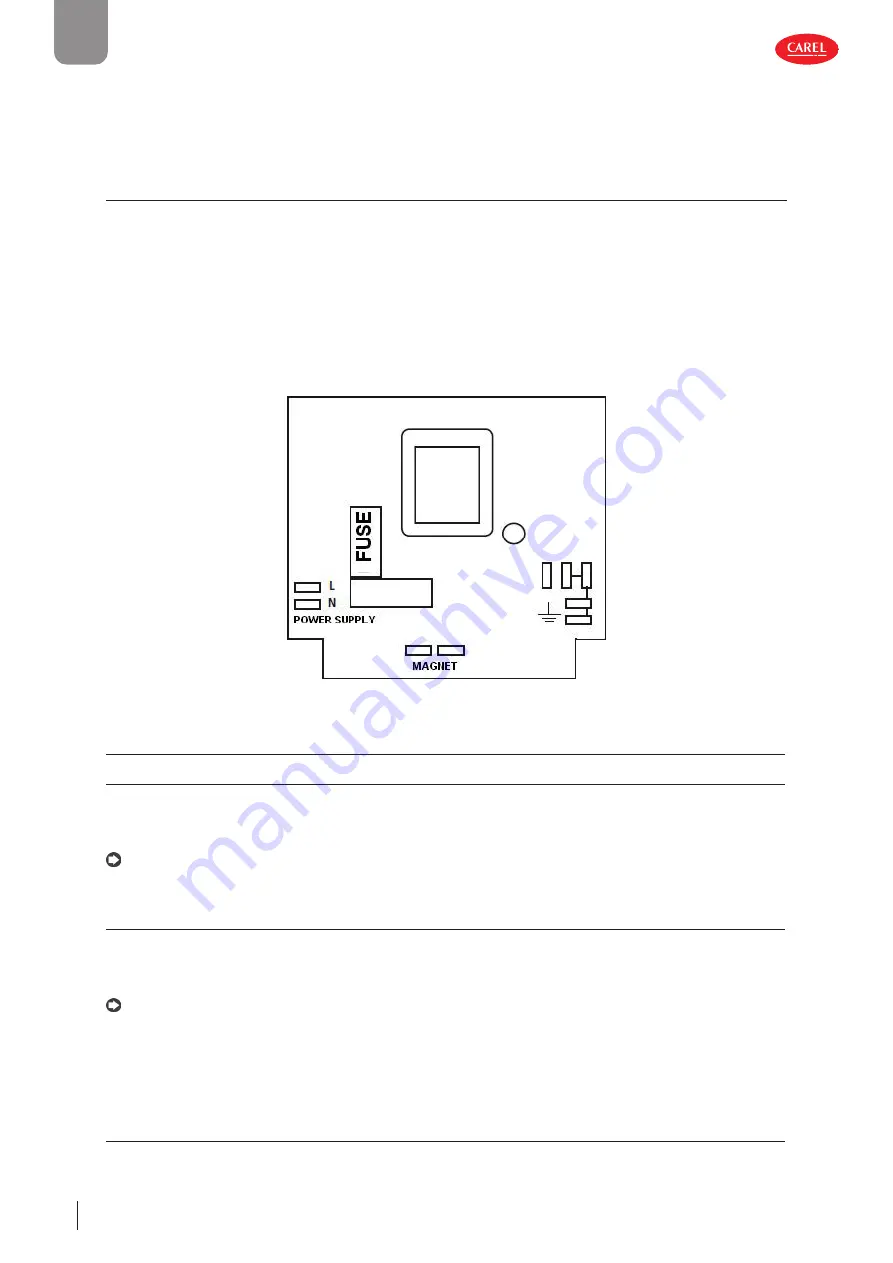

9.4.2 Replacing the metering pump fuse

The fuse on the metering pump shows only be replaced by specialist personnel. The replacement procedure is as

follows:

»

Loosen the 2 screws in the upper part of thepart of the pump

»

Holding the pump, remove the 6 screws at the rear

»

Slide out the rear part of the pump until it is completely detached from the front part, so as to access the

circuit at the front of the pump.

»

Be careful with the spring on the injection element shaft

»

Locate the fuse and replace it with an identical one

»

Reposition the rear part of the pump until it is completely coupled with the front part

»

Tighten the 6 screws on the pump

»

Replace the pump in the unit and tighten the two screws to the frame.

Fig. 9.b

9.5 Maintenance scheme

9.5.1 Daily maintenance

»

Check if the system is working cor- rectly.

»

Check that there are no leaks in the water-carrying components.

»

Check the water inlet pressure.

Notice:

The system supply pressure (after the pre-fil- ters) must be at least 2 bar during normal operation. Replace

the filter cartridges if the pressure loss is too high.

9.5.2 Weekly maintenance

»

Check the max. membran pressure (max.10 bar!).

»

Check the water conductivity of the permeate with the control unit.

»

Note down the data for the listed tests

Notice:

•

Note that the production quantity of the permeate increases with rising water temperature, while the quality

of Permeate is decreasing. Conversely, the production quantity decreases with decreasing temperature, while

the quality of the permeate improves.

•

The indication of the measured perme- ate conductivity value on the display of the control unit settles down

to the actual value within the first minutes.

9.5.3 Maintenance every two months

»

Check that there is not too much free chlorine at the outlet (less than 0.25ppm).

Summary of Contents for Large ROL 160-1K2

Page 2: ......

Page 6: ......

Page 43: ...43 ENG Control WTS LARGE 0300131IT rel 1 0 05 09 2022...

Page 59: ...59 ENG Spare parts WTS LARGE 0300131IT rel 1 0 05 09 2022 20 21 22 23 24 25 26 27 28 29 30...

Page 65: ...Notes...

Page 66: ...Notes...

Page 67: ......