26

ENG

“optiMist” +0300065EN - rel. 1.6 - 18/06/2021

7. CONTROL

7.1 Humidification

lgorithms, which can be selected from the installer menu.

• HH control:

modulates the capacity (water flow-rate) using two humidity probes, one

control probe normally installed in the AHU in the return air, and one limit

probe, usually installed downstream of the droplet separator.

• HT control:

modulates the capacity (water flow-rate) with two probes, one humidity

control probe and one limit temperature probe. This configuration is

recommended for systems in which a certainly humidity level is required

without however excessively cooling the air.

• H control:

like the HH algorithm but without the limit humidity probe;

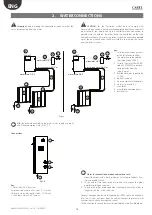

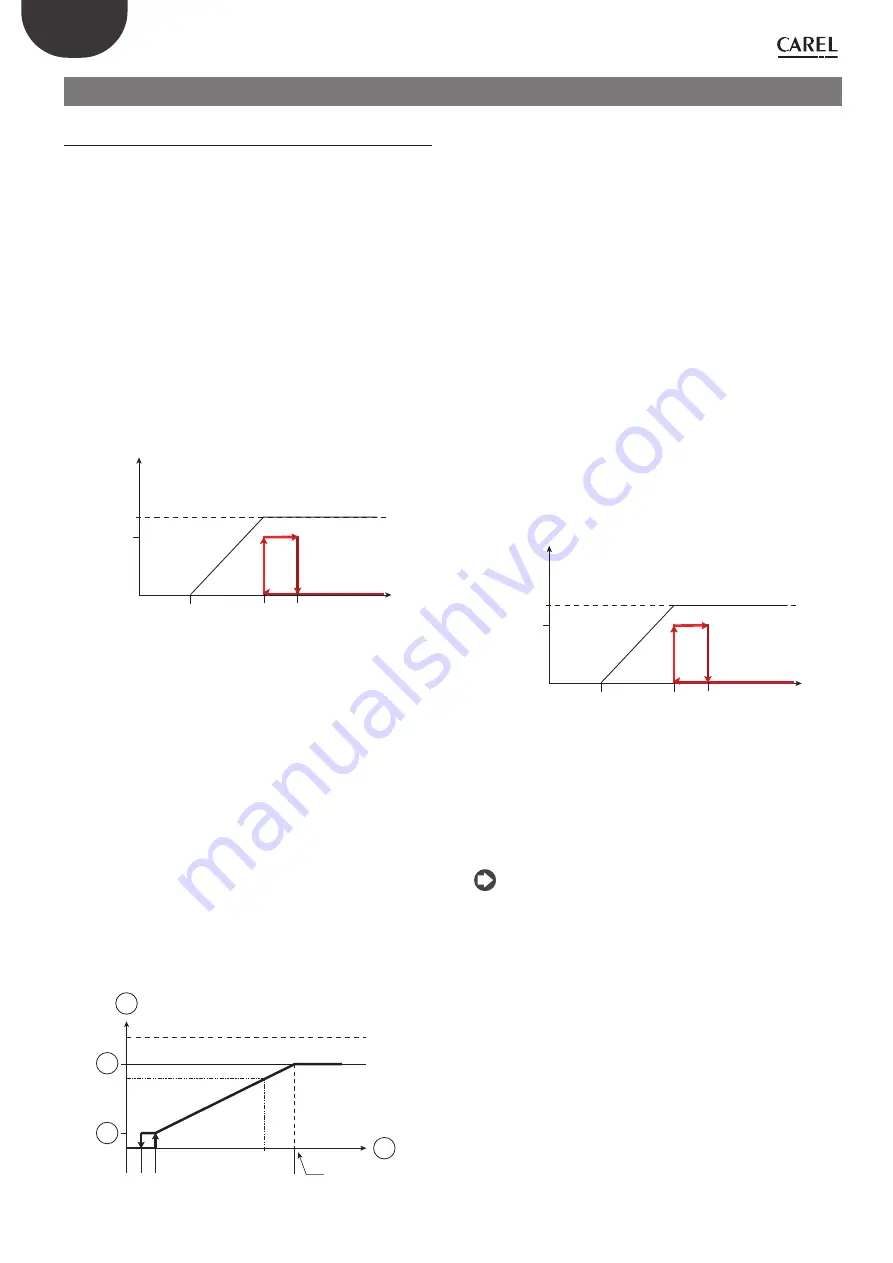

Below is the diagram of operation using humidity control probes

100%

Set + Diff

1

Set

Set - Band

% Rich.

T

Fig. 7.a

Key:

1.

production

2.

humidity control probe

3.

maximum production

4.

minimum production

5.

proportional band

6.

hysteresis (10% of “5”)

• PH/PT control:

capacity is modulated proportionally to an external control signal and is

limited based on the value measured by the limit temperature or humidity

probe. This is the typical configuration used in optiMist installations

connected to a Building Management System that generates a control

signal;

• P control:

like the PH/PT algorithm but without the limit humidity probe;

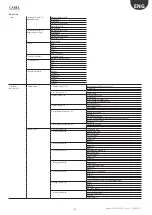

Below is the diagram of operation with proportional control.

100%

max

1

2

3

4

5% 5%

Fig. 7.b

Key:

1.

production

2.

external request

3.

maximum production

4.

minimum production

• CH/CT control:

operation in on/off mode, based on a voltage-free external contact (for

example, a humidistat). The capacity will thus be either the maximum

set or nothing, depending on the status of the external contact, and is

limited based on the value measured by the limit probe.

• C control:

like the CH/CT algorithm but without the limit probe;

The HH and TH algorithms are the most commonly-used, and

recommended for optiMist installations.

The limit humidity probe described above is usually set to high values, e.g.

80% rH, so as to limit the maximum moisture in the air introduced into the

duct and into the room. This is especially recommended in installations

where air flow-rate and operating, temperature and humidity conditions,

may change over time and, consequently an additional safety system is

required to prevent the humidifier from over-humidifying the air and, in

the worse case scenario, condensing in the ducts downstream.

Below are the two diagrams of operation with humidity or temperature

probes

100%

Set + Diff

1

Set

Set - Band

% Rich.

T

Fig. 7.c

Key:

1.

production

2.

limit probe

3.

maximum production

4.

minimum production

5.

proportional band

6.

hysteresis (10% of the set point)

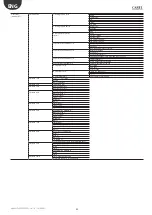

N.B.:

for convenience, the diagrams show continuous modulation of

the flow-rate while, depending on the model, control may be

continuous or in steps.

•

Temperature probe on the rack

The function, configurable under CONFIG. INPUTS 9 and 10, features two

distinct modes:

Warning only:

If the temperature is lower than the set point set on screen Bbc06,

calculated based on the system sizing, the “Low rack temperature”

warning is activated

W Reduction in production:

When the temperature drops below the set point, together with the

activation of the warning, production is reduced as the temperature

decreases, until it stops completely when the difference between the set

point referred to the temperature probe on the rack and the measured

temperature is higher than the “Band” set on screen 10.

Operation of the warning and production reduction modes is summarised

in the following graph, where all of the parameters indicated can be set

on the CONFIG. INPUTS screen.