39

ENG

“optiMist” +0300065EN - rel. 1.6 - 18/06/2021

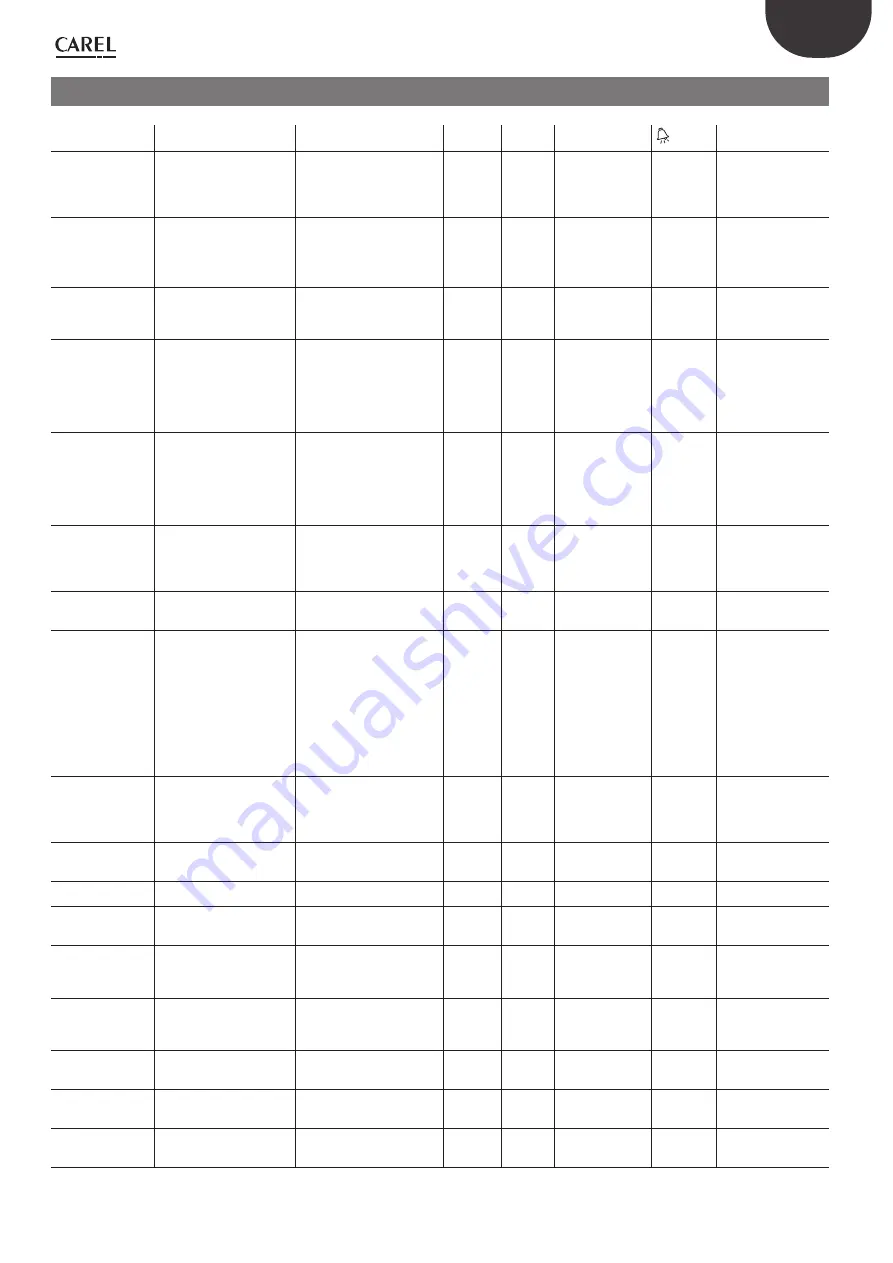

9. TABLE OF ALARMS

Message displayed

Cause

Solution

Reset

Alarm

status

Action

symbol

Notes

Water Treatment

System alarm

Dig. input Id6 open, check

any water

treatment unit

anomalies

Close dig. input ID6 with a

jumper, if the alarm disappears,

check the water treatment

system: if the alarm persists,

replace the controller

automatic active

stop production

on

Water Treatment

System warning

Digital input ID7 open/

closed (check logic): verify

water treatment system

anomaly

Close dig. input ID7 with

a jumper, if the alarm

disappears, check the water

treatment system: if the alarm

persists, replace the controller

automatic not active stop signalling

on

Inlet line low

pressure alarm

Low water pressure inlet

check supply circuit, water

supply pressure and if inlet filter

is clogged

automatic not active Stop production

on

check inlet pressure

three times before

generating next alarm

(LP Test)

High bypass

temperature alarm

excess water recirculation in

bypass

check operating temperature

(surrounding ambient air

and water); check that the

pressurised water distribution

system is not blocked so as to

cause water recirculation in the

pump.

automatic not active signal only +

opening of cabinet

drain valve for 10

s ?*

on

* make sure there is no

LP alarm from the probe

during these 10s.

High bypass

temperature alarm

excess water recirculation in

bypass, warning active for 60s

check operating temperature

(surrounding ambient air

and water); check that the

pressurised water distribution

system is not blocked so as to

cause water recirculation in the

pump

automatic active

Stop production

on

Inverter VFD alarm

inverter fault

check the status of the inverter

and replace if necessary

Note*

active

Stop production

on

* automatic reset on

the inverter control

depends on the type

of alarm, see chapter 7

inverter manual

Low pump cabinet

temperature alarm

water inlet temperature less

than 5°C

heat supply water or the

cabinet with a suitably rated

heater*

automatic active

Stop production

on

* possibility of activating

the defrost

Droplet separator

clogged alarm

droplet separator clogged

check the status of the droplet

separator(s)

manual

active

Stop production

on

* signal given by a

differential pressure switch

that sees an upstream-

downstream pressure

difference for the droplet

separator. When there

are 2 droplet separators

(HumidifIEC), 2

pressure switches will be

connected in series. P

selectable, delay selectable

High pressure

warning from

pressure probe

outlet pressure greater than

20 bars

check bypass valve calibration

automatic active

signal only

on

* before arriving at 20

base, the "Auto-tuning"

procedure causes the

system to operate at a

max of 15.5 bars.

Distribution system

maintenance request

warning

the flow-rate is 40% lower

in comparison to the MAX

production set.

The SW continues auto-tuning

automatically Check if the

distribution system is clogged

automatic not active signal only

on

Low pressure warning

from pressure probe

outlet pressure less than 1

Bar*

check tightness of outlet water

circuit

manual

active

Stop production

on

* threshold settable by

parameter

Pressure probe

broken or

disconnected alarm

pressure probe broken or

disconnected

check connection and

operation of the pressure probe

manual

active

Stop production

on

* active only if

configured

Main probe

(Humidification)

broken or

disconnected alarm

main probe disconnected or

broken

check connection and

operation of the main probe

manual

active

Stop production

on

* active only if

configured

Secondary probe

(Humidification)

broken or

disconnected alarm

secondary probe

disconnected or broken

check connection and

operation of the secondary

probe

manual

active

Stop production

on

* active only if

configured

Main probe

(IEC) broken or

disconnected alarm

main probe disconnected or

broken

check connection and

operation of the main probe

manual

active

Stop production

on

* active only if

configured

Secondary probe

(IEC) broken or

disconnected alarm

secondary probe

disconnected or broken

check connection and

operation of the secondary

probe

manual

active

Stop production

on

* active only if

configured

Auxiliary probe

broken or

disconnected alarm

auxiliary probe disconnected

or broken

check connection and

operation of the auxiliary probe

manual

not active signal only

on

* active only if

configured