2012 Cargo Floor B.V. Coevorden, Holland

Versie 01/11-01-2012

www.cargofloor.com

info@cargofloor.com

Cargo Floor B.V.

P.O. Box 271

NL-7740 AG Coevorden

Phone: +31-(0)524-

593900

Fax: +31-(0)524-

593999

Blz. 31

GB

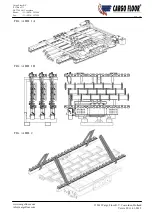

SECURING THE SYSTEM

After the Cargo Floor system has been correctly positioned it can be secured to the chassis / frame by welding or

by bolting.

Welding

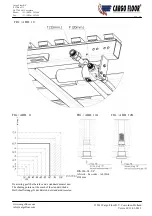

Good quality welds, of the appropriate lengths, need to be made at the points indicated in the drawing (see figure

7).

Use a weld width of a = 10.

Bracing of the Cargo Floor system is not necessary.

Pay attention to that if the sub frame is zinced (as option with at SL-2 system) the spots that need to be welded are

cleansed of the zinc coating.

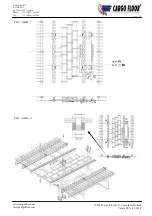

Bolting

The Cargo Floor system can, if desired, be bolted to the chassis / frame. The holes in the chassis / frame need to be

concentrically aligned with the holes in the Cargo Floor system. 6 Bolts per side need to be used on the rear bridge

(see figure 8) and 1 bolt per side in the so-called front bridge. This results in a total of 14 bolt connections. Each

bolt needs to be secured with a spacer and two self-locking nuts. (See figure 8.)

All bolts must conform to the following specification:

14 pieces M16x80 ELVZ (DIN931-10.9)

Quality 10.9.

28 pieces nut M16 (double, nut with self-locking nut)

28 pieces washer Ø 30 / Ø 17, dik 3 mm (DIN125)

14 pieces spacer ST52-3 Ø 30 / Ø 17, length 20 mm

Torque 300 Nm

For an aluminiun chassis we can advise, as an alternative, to use a strip (thickness 20mm) with corresponding hole

pattern.

Tool size for M16 bolt: Spanner size 24