13

ENGINE

INSTALLATION

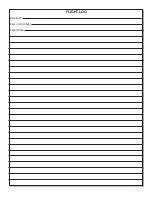

FIT THE ENGINE

❏

1. Fit the engine to your engine mount so that the drive

washer of the engine is

5-7/8" [149mm]

from the base of the

mount (fi rewall). Use a minimum of 8-32 bolts to attach the

engine to the mount (these are not supplied with the kit). Drill

and tap your mount.

❏

2. Make index marks between the two sliding rails. This

will help you note the position of the rails for the next step.

❏

3. Remove the engine from the mount, keeping the two

sides of the mount together.

❏

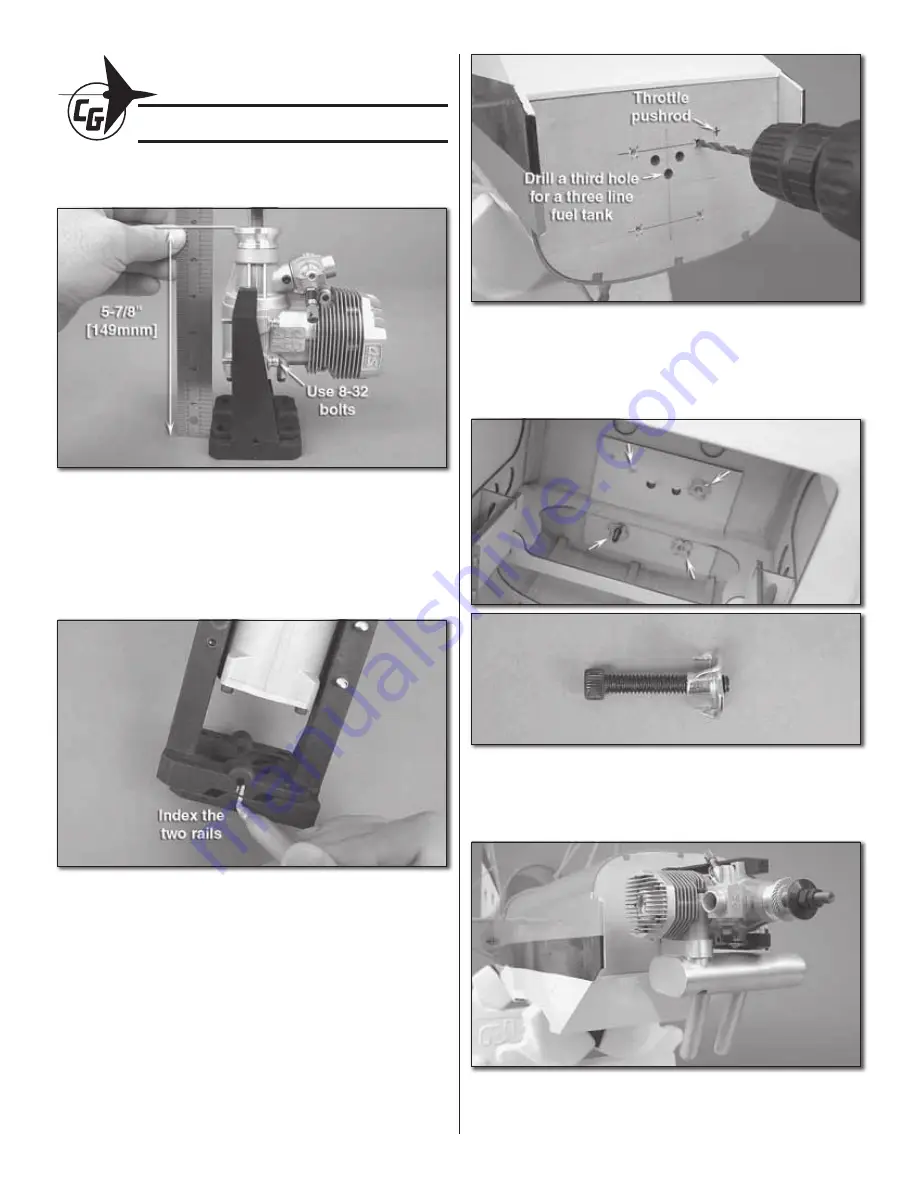

4. Center the engine mount over the cross-hairs etched

into the fi rewall. Be careful to note the position of the mount

so that the cylinder head is oriented on the proper side of the

fuselage. Mark the location for the engine mount bolts and

where you will need to drill the hole for the throttle pushrod.

❏

5. Drill four 7/32" [5.6mm] holes for the engine mount

bolts. Drill a 5/32" [4mm] hole for the throttle pushrod while

you’re at it. If you’re going to use a three line fuel tank setup,

go ahead and drill a third hole now. Use a 7/32" [5.6mm] drill

bit for this.

❏

6. Locate the four (4) 8-32 x 1" [25mm] engine mount bolts

and their associated 8-32 blind nuts. Press the blind nuts into

the back side of the fi rewall. You can use the bolts to help you

pull the blind nuts into position.

❏

7. Bolt the engine and the engine mount to the fi rewall.

Temporarily attach the muffl er.

13