❏ ❏

6. Hold the aileron in its full defl ected position as you’re

pushing in and apply 10 to 12 drops of thin CA to each hinge. Turn

the wing over and apply CA to the opposite side of the hinges.

❏

7.

Repeat steps 4 through 6 for the other ailerons.

SERVO & CONTROL HORN INSTALLATION

❏

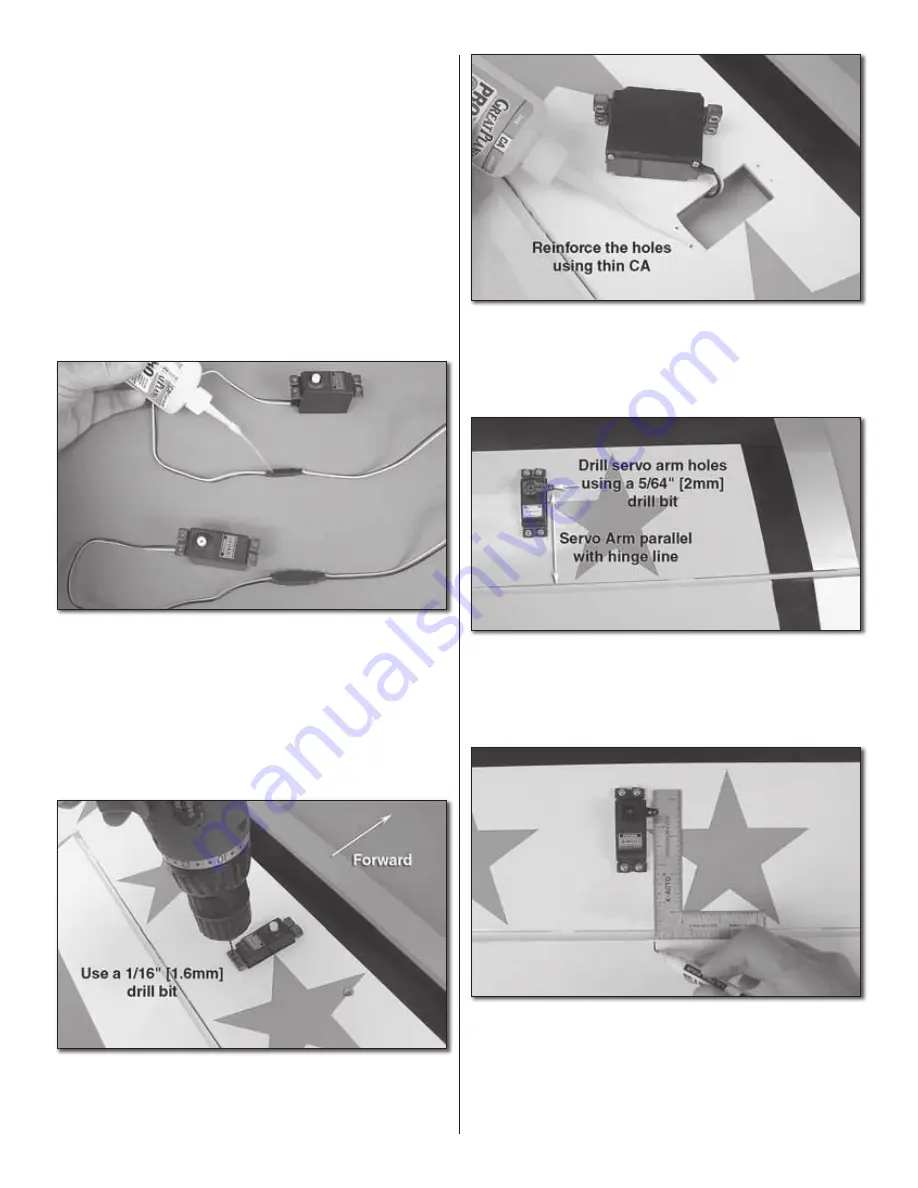

1. Gather four (4) servos and four (4) 12" [305mm] servo

extension leads. Attach a lead to each servo. To secure the

leads, use a piece of heat shrink tubing over the connection OR

place a drop of medium CA along the seam of the connection.

❏

2. Tie a guide string to the end of each servo lead and carefully

pull the lead through the wing. You may have to move the lead

back and forth in the wing in order to clear each rib, so be careful.

Save your guide strings for the elevator servo installation.

❏

3. Position the servos in the servo bays with the output

shaft facing forward. Using a 1/16" [1.6mm] drill bit, drill the

holes for the servo mounting screws.

❏

4. Use the screws that came with your servos to tap the

holes. Remove the screws and place a drop of thin CA into

each hole. This will harden the wood and will keep the screws

from loosening over time.

❏

5. Use your radio to center your servos and install servo

arms on each servo so that the arm that faces outboard is

90 degrees to the servo case and is parallel with the hinge

line. Drill the holes with a 5/64" [2mm] drill bit. Cut off the

remaining arms.

❏

6. Use a straightedge or a builder’s square to mark the

position of the control horn centerline directly behind the third

hole out from the center of the servo. Do this for each aileron.

❏ ❏

7. Locate four (4) control horns, four (4) backplates and

twelve (12) 2-56 x 1" [25mm] machine screws. Have your drill

ready with a 3/32" [2.4mm] drill bit.

4