NOTE:

When handling the motor and switch harness,

try to avoid bending the wires near the soldered con-

nections. If handled carelessly, these joints can be bro-

ken.

The following instructions are for installing the Turbo

550 motor. If using another motor, you may need to

modify the installation according to the motor manu-

facturer’s instructions.

IF USING A 2-CHANNEL INSTALLATION, PRO-

CEED TO STEP 4 and return to the fuselage side

view on the plan for switch location..

1.

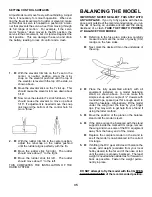

For a 3-channel installation

, remove the lock

washer and nut from the top of the switch and

insert the ply mounting plate, as shown.

2.

Locate switch mount just forward of former “B”

and about 1/2” below the top edge of the fuse

side. Refer to the top and side views on the

plan.

NOTE: The motor switch body must be turned, so the

switching action aligns with the pushrod from the motor

servo.

When satisfied with the position, glue the

switch mount to the fuse side and former “B”.

4.

Insert the motor through from the rear of

Former “A”, so that the motor front protrudes

about 1-3/4” out from the front of the fuse. Hold

the motor in its mount, using rubber bands.

For 2-channel only, drill or cut a 1/4” dia. hole

through the fuse side and mount the switch.

5.

Using a scissors, carefully remove excess

plastic from the base of the cowl.

Using a sharp hobby knife, rather than the scis-

sors, cut motor and vent holes. Do not try to

“force” the knife, since it could slip and damage

either the part or you. Instead, make a series

of light cuts, each a little deeper than the last.

6.

Referring to the fuse side view on the plan for

the location of the screws, mark the location of

the screws and drill four 1/16” holes through

the cowl.

Set the canopy in place on the fuse and then

position the cowl over the fuse front and the

canopy.

When satisfied with the fit, screw the cowl in

place.

6.

Thread a #4 socket set screw in the prop

mount and turn a few times.

Open the spinner supplied by carefully insert-

ing a small screwdriver straight into each of the

slots.

DO NOT TWIST! JUST PRY OPEN.

NOTE: Carefully read the instructions included with

your spinner. Rehydrating of the plastic will

make it easier to open and close the spinner .

When the spinner backplate has been

removed, place it on the propeller mount.

FUSE TOP VIEW

3.

Using a 7/64” drill, enlarge the nylon bracket to

fit snugly on the switch. You may need a mod-

eling knife to make the hole slightly larger than

7/64”.

With the bracket flange parllel to the switching

action, glue the bracket to the switch.

30

#4 SET SCRES

LARGE WASHER