10

6

.

Repeat for the other three horns.

7

.

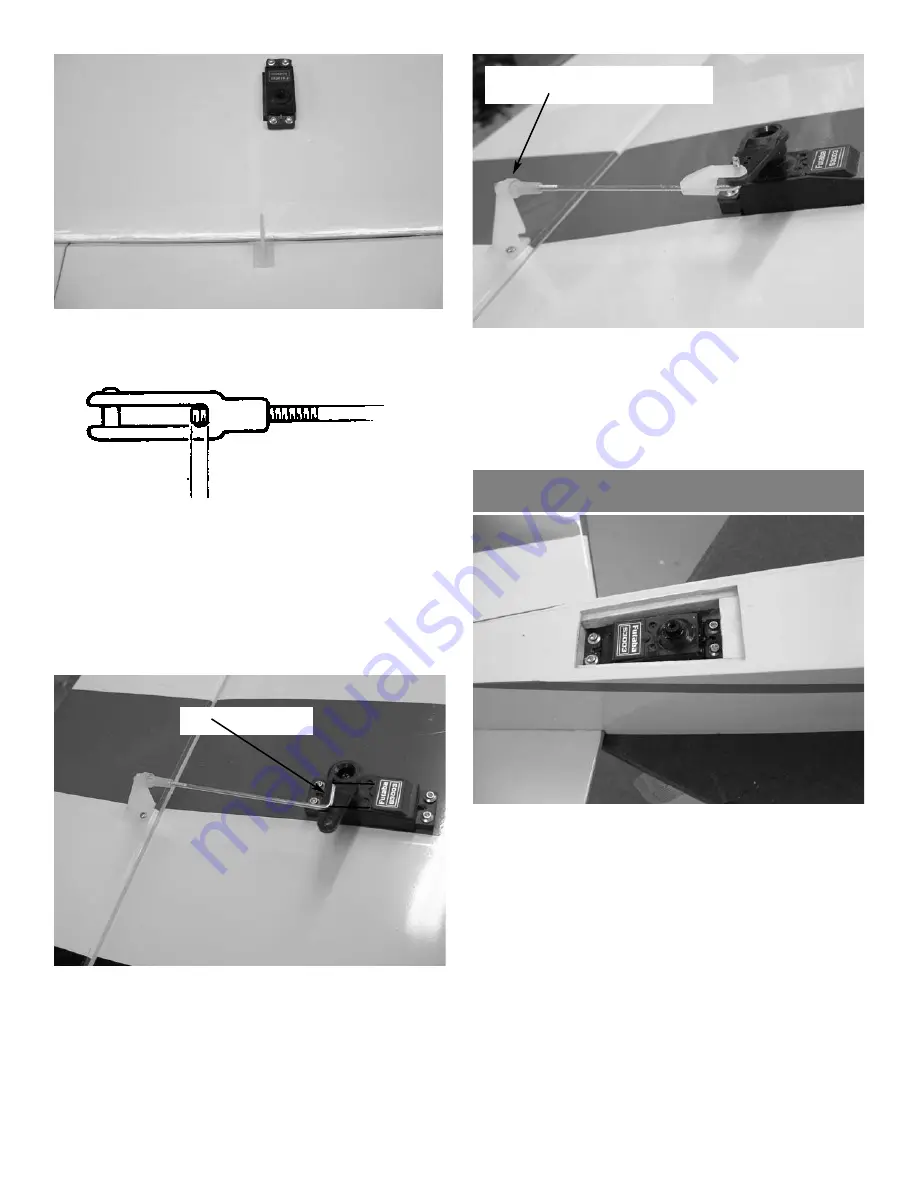

Locate the four 2-56 x 6” pushrods and install

the nylon snap link on the end. Thread the rod

into the snap link until 1/16” extends into the

opening. Slide the silicone tubing clevis keep-

er over the snap link.(silicone tubing 1/4” long)

1/16”

8

.

Install the snap link on the control horn. With

the aileron servo centered and the aileron

level, mark the point where the pushrod cross-

es the control arm on the servo and make a 90

degree bend. But the bend off at 3/8”. To get

full potential out of the plane you will need a

heavy duty servo arm 1 to 1-1/4” long.

3/8”

9

.

Install the pushrod in the servo output arm

and retain with the nylon swing in keeper.

Push the silicone clevis keeper down to the

control horn.

10

.

Repeat for the other aileron and both flaps.

silicone tubing keeper

Rudder Servo Installation

1

.

Mount the rudder servo in the opening provid-

ed on the bottom of the fuselage just in front

of the stab. You will need a 1” extension on

the servo lead. Be sure to tape the plug

together so it does not come loose.