7

3.

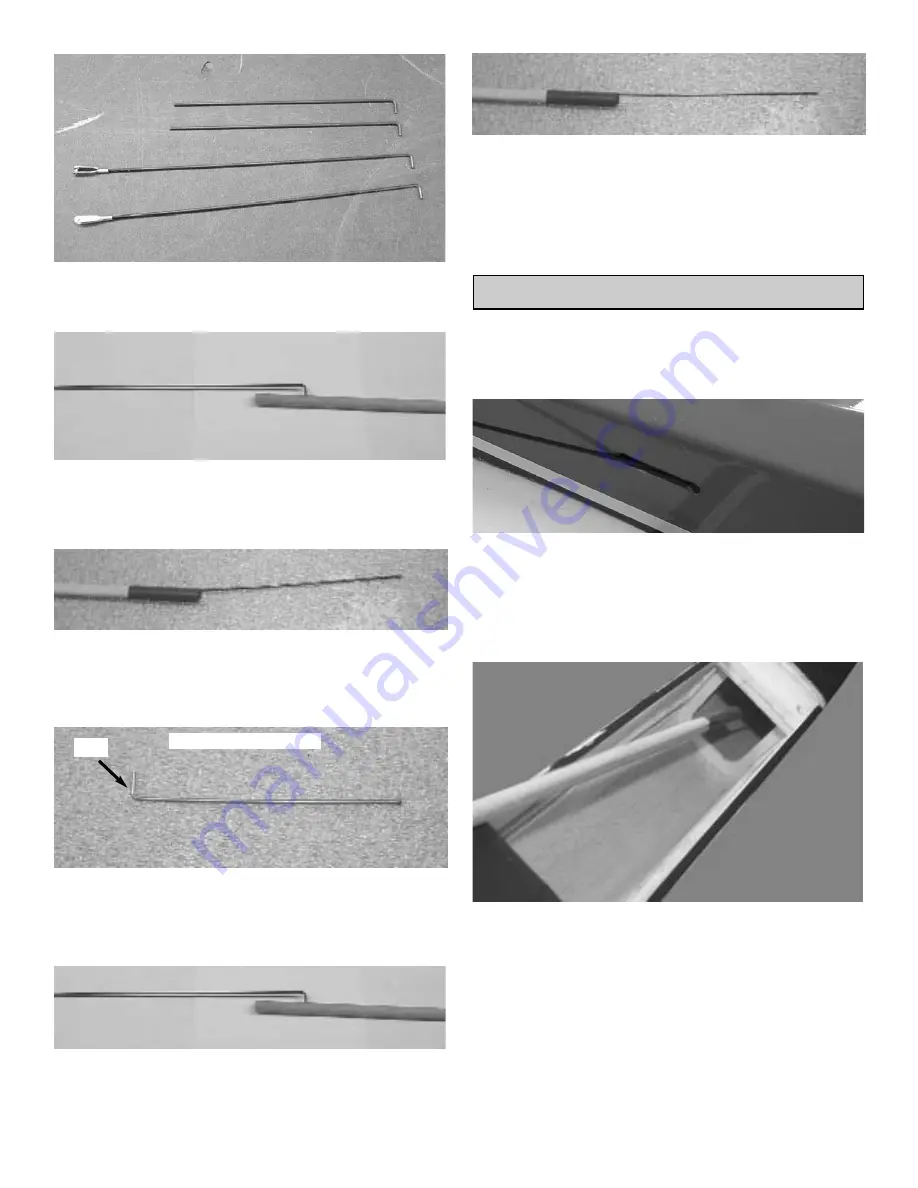

Make a 90 degree bend.

Cut the wire 1/4” past the bend.

4.

Insert the wire into the hole in the wood

pushrod and push down into the groove.

Glue the wire to the wood pushrod using Ultra

Set medium CA glue.

5.

Slide the heat shrink tubing over the pushrod

and shrink using a blow drier.

Glue the tubing to the wood pushrod using

thin CA glue.

This finishes one end of the elevator pushrod.

1/4”

NON THREADED WIRE

6.

Starting at the non-threaded end of the 1.5mm

x 15cm wire, bend the last 1/4” up at a 90

degree angle.

7.

Insert the wire into the hole in the wood

pushrod and push down into the groove.

Glue the wire to the wood pushrod using Ultra

Set medium CA glue.

8.

Slide the heat shrink tubing over the pushrod

and shrink using a blow drier.

Glue the tubing to the wood pushrod using

thin CA glue.

This finishes the elevator pushrod.

Repeat for the rudder pushrod.

INSTALLING PUSHRODS

1.

Collect the following parts

(1) Elevator Pushrod

(1) Rudder Pushrod

(1) Fuselage

2.

Find the hole under the stabilizer on both

sides of the fuselage.

Cut the covering over each of the push rod

exit holes. Note that there are two slots on

each side. Use the one closes to the stab on

the right side (elevator) and the lower one on

the left side (rudder).

3.

Insert the rudder pushrod into the fuselage

through the wing saddle area.