12

90˚

90˚

6. Connect the servos to your receiver and power up the

system with the trims on the transmitter centered. Fit the

servo arms on the servos so they will be as close to 90

degrees as possible to the pushrods (but they don’t have to

be perfect). Cut off the unused servo arms.

7. Use a #55 (.052"

[1.3mm]) drill or a

hobby knife to enlarge

the holes in the servo

arms. Then, mount a

screw-lock connector

to each arm using

the nylon retainer as

shown.

8. Fit the pushrods

into the screw-lock

connectors on the

servo arms. Position

the servo tray wherever the servos align with the pushrods.

Securely glue the servo tray into place.

9. One last time, turn on your radio and power the

servos. Center the elevator and rudder. Next, add a drop

of threadlocker to the screws in the screw-lock connectors

and tighten them down. Cut the pushrods approximately 1/2"

[10mm] past the screw-locks.

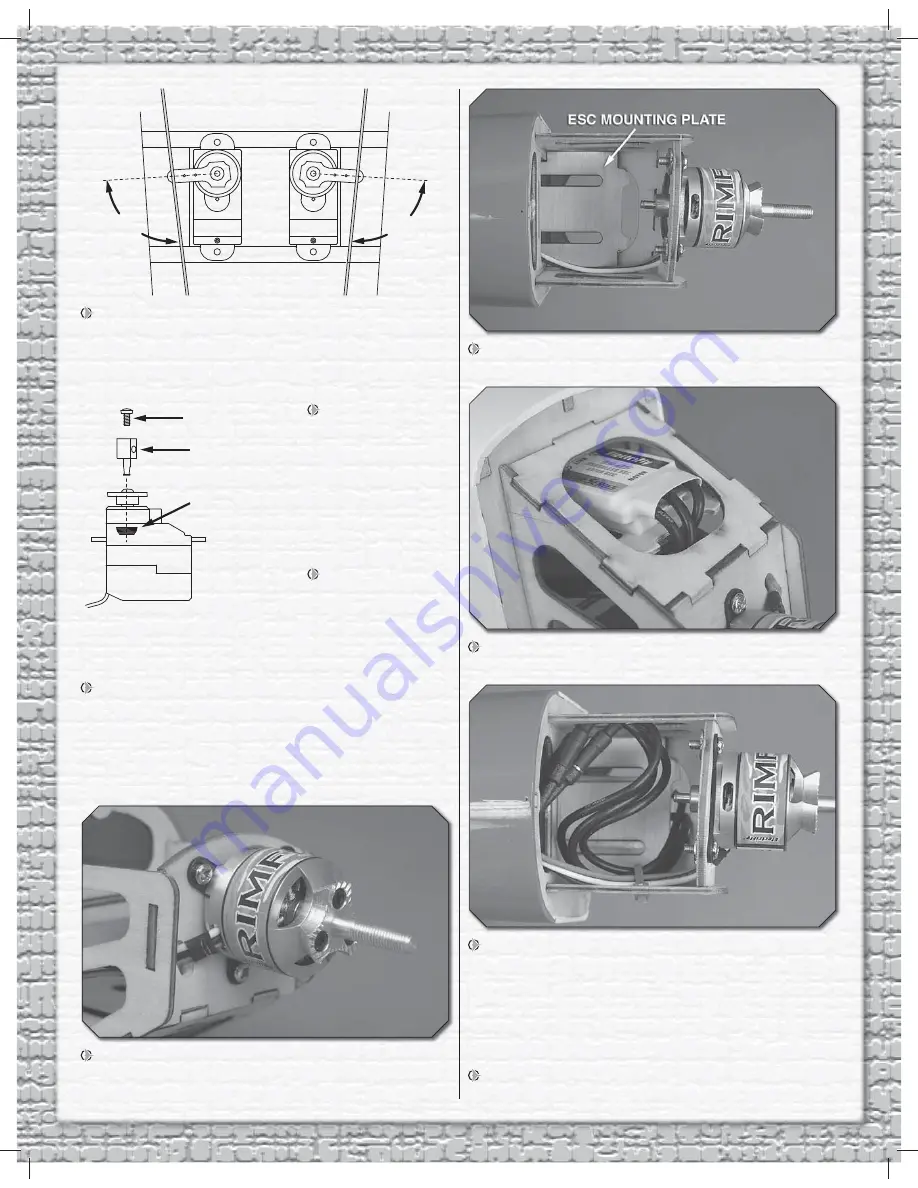

MOUNT THE MOTOR AND ESC

1. Guide the motor wires through the hole in the fi rewall

and mount the motor with three 3 x 8mm Phillips screws and

a drop of threadlocker on the threads.

2. Fit, then glue the plywood

ESC mounting plate

into position.

3. Mount the ESC to the ESC mounting plate with double-

side foam mounting tape (not included).

4. Using 3.5mm male bullet to 2.0mm female bullet

adapters (GPMM3122, not included), connect the ESC wires

to the motor wires, keeping as much of the wiring as you

can in front of the fuselage in the cowl area so it will not be

in the way of the battery—when installing the battery later, it

should be placed forward to reduce any nose ballast that will

be required to get the proper C.G.

5. Turn on the radio and connect the battery to momentarily

power up the system. Make certain the motor turns and does

SCREW

RETAINER

SCREW-LOCK

CONNECTOR