Model 99FRD, 100CRD & 102CRD oil burners — Instruction manual

Carlin part number MN99102 Rev. 08/20/08

– 4 –

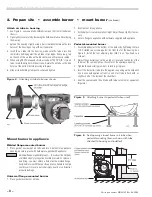

2. Prepare site • assemble burner • mount burner

Inspect/repair/replace vent system

Do not install this burner unless you have verified the entire

vent system and the appliance are in good condition and

comply with all applicable codes. And ...

• The vent and chimney must be sized and constructed in

accordance with all applicable codes.

• Do not install or use an existing manual damper in the

breeching (vent connector) or chimney.

• Do not connect the appliance vent connector to a chimney

or vent serving a fireplace, incinerator or solid-fuel-burning

apparatus.

• In a cold climate, do not vent into a masonry chimney that

has one or more sides exposed to the outside. Install a listed

stainless steel liner to vent the flue products.

• A defective vent system could result in severe personal

injury, death or substantial property damage.

Prepare vent/chimney

• Secure all metal vent joints with screws, following the vent manufacturer’s

instructions. Seal all joints in the vent system and chimney. Repair masonry

chimney lining and repair all mortar joints as needed.

• Install a double-acting barometric draft regulator in the vent piping if speci-

fied in the appliance manual. (The damper must be located in the same

space as the appliance.)

• Provide support for the vent piping. Do not rest the weight of any of the

vent piping on the appliance flue outlet.

Table 2

Minimum combustion/ventilation air openings

Combustion/ventilation air openings

Check appliance manual and applicable codes for required sizing/design/

placement of combustion/ventilation air openings. You can use the follow-

ing general guidelines, taken from NFPA 31, provided they meet all local

requirements.

Louvers/screens

• Air opening sizes are always given in free area. This means after deduction

for louver obstruction. If you can’t find the louver reduction for the grilles

used, assume free area is 20% of total for wood louvers, or 60% of total

for metal louvers.

• Screens can be no finer than ¼-inch mesh, and must be accessible for

cleaning.

Residential installations

Unconfined spaces (at least 7,000 cubic feet per GPH)

• An unconfined space means a room with at least 7,000 cubic feet volume

for each GPH input (or 50 cubic feet per MBH) of all appliances in the room.

Example: For each 1 GPH oil input, the room must have 7,000 cubic feet

(875 square feet with an 8-foot ceiling height.)

• Open basements and crawl spaces are usually large enough, and will

generally allow enough air infiltration so special provisions will seldom be

required.

• If the building is tightly constructed, you will have to provide outside air

openings into the building. The total free area of the openings must be

at least 1 square inch per 5,000 Btuh (28 square inches per GPH) of all

appliances in the space.

•

See Table 2 for summary

.

Confined spaces (less than 7,000 cubic feet per GPH)

• Air taken from inside building only —

• Provide two openings — one near floor, the other near ceiling. Provide free

area of 140 square inches per GPH input. If building is tightly constructed,

provide air opening(s) into building providing 30 square inches per GPH as

well.

• Air taken from outside —

• Direct through outside wall or vertical ducts: Provide two openings — one

near floor, the other near ceiling. Provide free area of 35 square inches per

GPH input.

• Through horizontal ducts: Provide two openings — one near floor, the other

near ceiling. Provide free area of 70 square inches per GPH input.

• Ventilation air from inside/combustion air from outside

• Size openings to interior to provide 140 square inches free area per GPH

input. Size outside air duct to provide 28 square inches free area per

GPH.

• See Table 2 for summary.