Model 99FRD, 100CRD, & 102CRD oil burners — Instruction manual

Carlin part number MN99102 Rev. 08/20/08

– 5 –

Combustion/ventilation air checklist

The burner may operate successfully under momentary

downdraft conditions, but sustained downdraft is unsafe.

This can occur with an inadequate or incorrectly installed

chimney/vent. It can also occur in rooms/buildings equipped

with exhaust fans or unsealed return air ducts. Always check

operation of the burner under all conditions to verify vent system

operates correctly. You may have to interlock the burner with

exhaust fans to shut burner off when fan operates; or provide

make-up air to the appliance room sufficient to prevent any

negative pressure in the space. Failure to correct downdraft

or negative room pressure operation could result in severe

personal injury, death or substantial property damage.

❏

Verify that openings are unobstructed.

❏

Verify that appliance space and air source spaces are free of:

• Gasoline or other flammable liquids or vapors.

• Combustible materials.

• Air contaminants and chemicals, such as laundry products, paint, thinner,

varnish, etc.

❏

Confirm with the building owner that the area will be kept free of these

materials at all times and that air openings will be kept unobstructed.

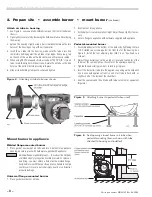

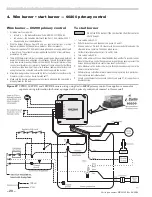

2. Prepare site • assemble burner • mount burner

(continued)

Verify combustion chamber

Chamber dimensions and construction

• If retrofitting the burner to an appliance, install the burner in accordance

with the appliance instruction manual, when available. If no specific

application data is available from the appliance manufacturer, read the

guidelines in Figure 1, page 6, to check whether the burner is likely to

work acceptably in the application.

Verify clearances

Verify that the burner/appliance will maintain all clearances from combus-

tible construction and clearances for service/maintenance as required in

the appliance manual and applicable codes.

Verify that the vent system components maintain all necessary clearances

to combustible construction, including the correct design of thimbles and

insulation where penetrating combustible walls.

• Illustrations A to F in Figure 1 show different chamber configurations

with and without refractory linings. The chamber dimensions listed in

Figure 1 depend on whether the chamber is lined or water-backed.

• Do not attempt to fire the burner in a chamber with dimensions smaller

than shown in Figure 1, page 6, unless the application has been specifi-

cally tested and listed by the appliance manufacturer and/or Carlin.

• Chambers with dimensions larger than shown in Figure 1, page 6,

should not have much effect on combustion/performance.

General guidelines

• Clean all appliance flues and heating surfaces thoroughly, removing all

soot and scale.

• Seal all joints and gaps using furnace cement to prevent excess air

infiltration.

The 99FRD wrapped-shield air tube must be used only in

wet-base combustion chamber applications.

Using chamber linings and lightweight chambers

• When using refractory liners or lightweight chambers, use insulating-

type refractory rated 2300°F minimum.

• You must install a target wall liner if flame length is close to the length

of the chamber.

• Use a floor liner when possible. The floor liner will improve firing in most

applications. Extend floor liner 3 to 4 inches up side wall.

• Target wall liners — Corbel the top of target wall liners 1½ to 2½ inches

deep and extend at least 3 to 4 inches above the center of the flame.

• Use pre-formed chamber liners when available.

• For firing rates below 0.75 GPH, it is best to apply in a refractory-lined

or stainless tube (designed for application) chamber. Lining the floor

and target wall of the chamber with lightweight insulating refractory

will accomplish the same.

• When conversion firing coal-fired units, install a combustion chamber in

the ashpit area, or fill ashpit with sand up to 2 inches above the “mud

ring” of a boiler (firing through the door). Install a lightweight refractory

liner on the target wall as in Figure 1F, page 6. Make sure the minimum

dimensions comply with those for Figure 1F.