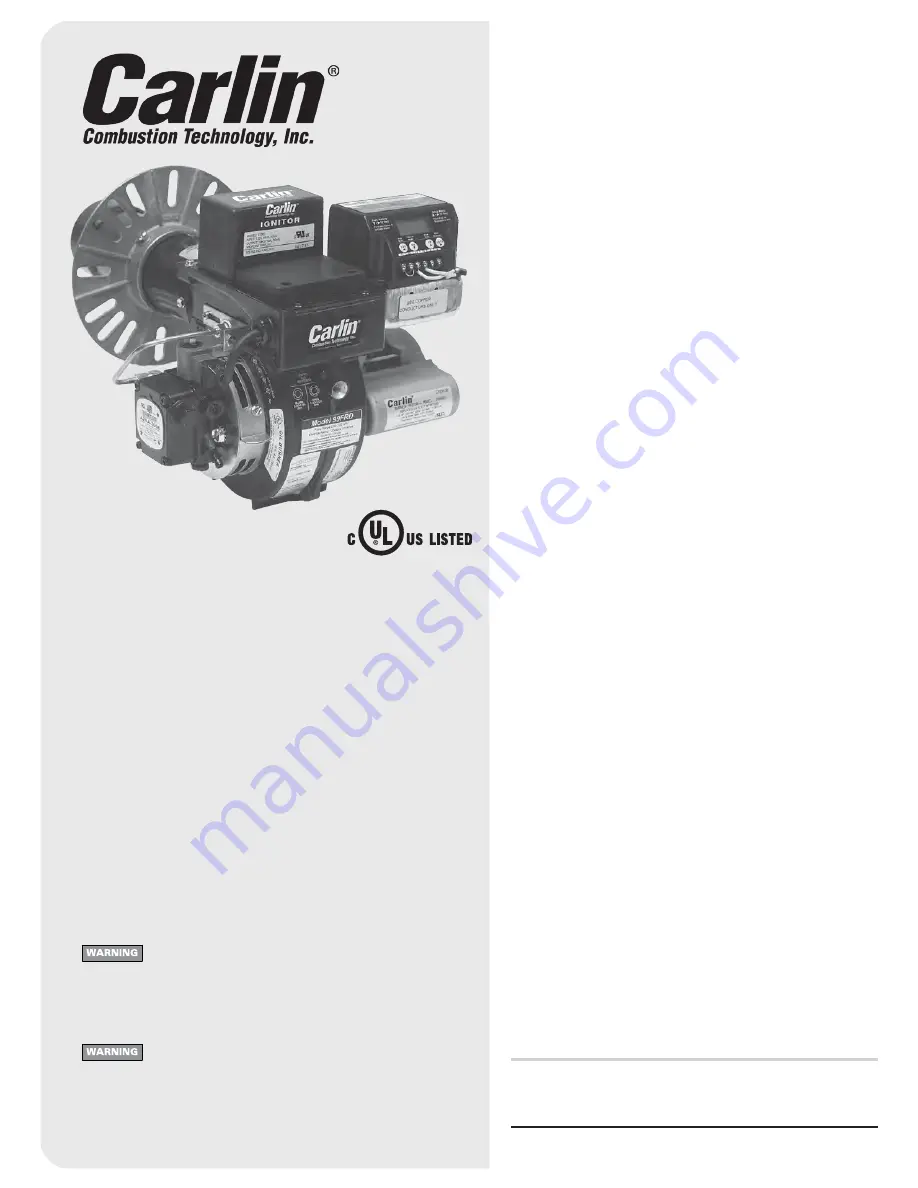

99FRD

102CRD

EZ-66

Models

Advanced Oil Burners

0.5 to 4.5 GPH

Instruction Manual

Contents

PLEASE read this first .......................................................2

Codes and Standards ........................................................2

1. 99, EZ-66 & 102 Oil Nozzle Selections ........................3

2. Prepare Site • Assemble Burner • Mount Burner........4

3. Prepare Burner ............................................................9

4. Adjustment and Verification .......................................14

5. Annual Start-up and Service ......................................15

6. Repair Parts ...............................................................16

7. Maintenance Procedures ...........................................18

User care and maintenance ...............................Rear cover

Installer/servicer – Except where specifically stated other-

wise, this manual must be used only by a

qualified service

technician

. Failure to comply with this or other requirements

in this manual could result in severe personal injury, death or

substantial property damage.

User – Refer only to User care and maintenance on back page

for information regarding operation of this burner. The burner

Instruction Manual is intended only for your service technician.

The burner and heat exchanger must be inspected and started

at least annually by your service technician.

Ratings

Input:

99FRD, EZ-66 .........................................0.50 to 3.00 GPH

102CRD (2

5

/

8

" air cone) ........................ 2.00 to 3.50 GPH

102CRD (3" air cone) ............................ 3.00 to 4.50 GPH

Fuels: U.S. ................................................No. 1 or No. 2 Fuel oil

Canada .................... No. 1 Stove oil or No. 2 Heating oil

Fuel unit:

...............................................................................Suntec

........................................ 100 to 150

psig

nozzle pressure

Electrical: Power ..............................................120V/60 Hz/1-Phase

Motor................................Carlin PSC, 1/6 HP, 3450 RPM

Current

99FRD, EZ-66 ..............................Approx. 5.5 amps

102CRD .......................................Approx. 6.0 amps

Ignition:

.................Carlin Model 41000 electronic – 19,000 volts

Control:

........................... U.L. Group I or II primary safety control

Agencies:

...............................................UL Listed (US and Canada)

126 Bailey Road

North Haven, CT 06473

Ph 203-680-9401

Fx 203-680-9403

Carlin Combustion Technology, Inc.

T

ech

support

800-989-2275

carlincombustion.com

©

Copyright 2015 — Carlin Combustion Technology, Inc.