Model 301GAS burner — Instruction manual

Carlin part number MN301GAS Rev. 11/24/14

– 8 –

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner

(continued)

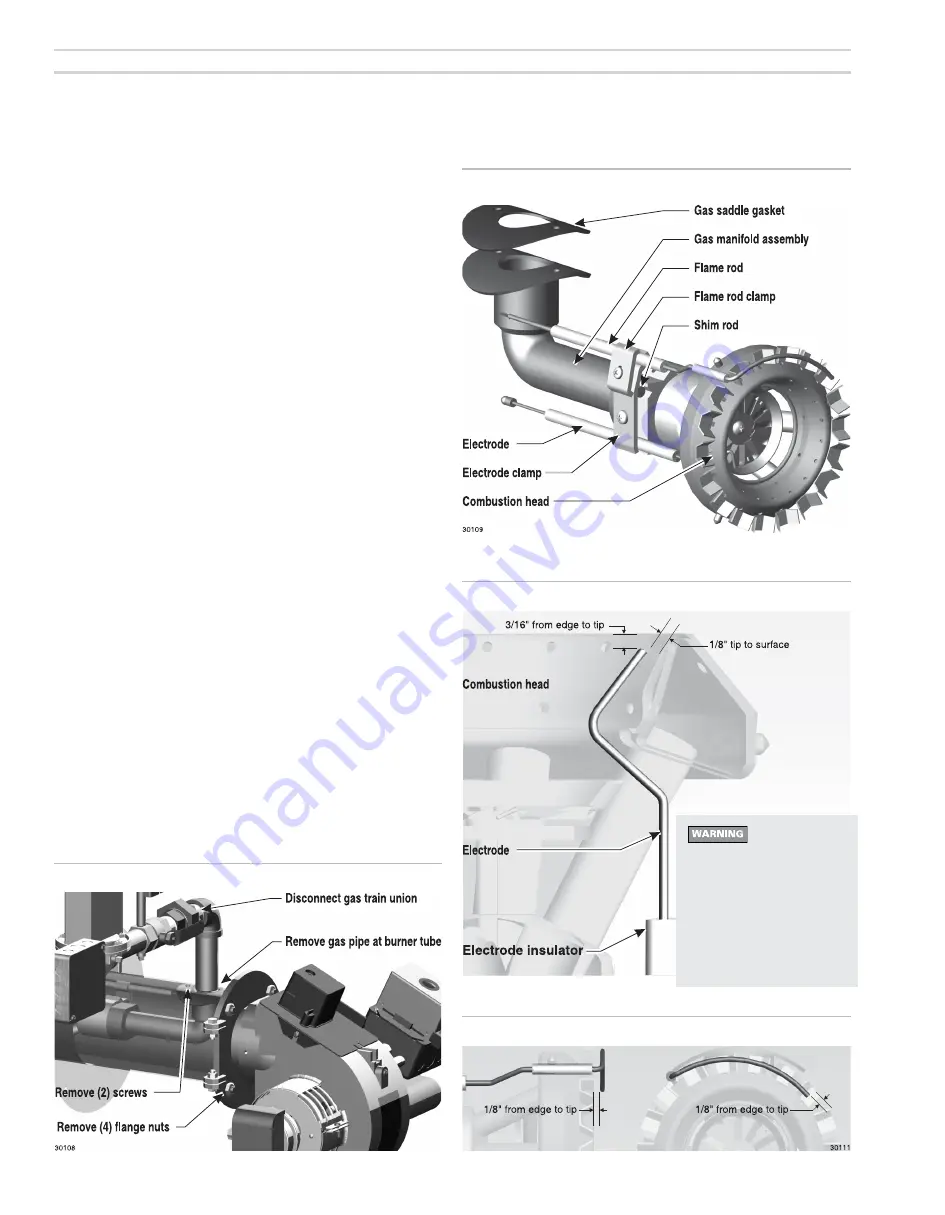

Figure 5

Combustion head

Figure 4

Removing combustion head/gas manifold

Inspect/correct flame rod/electrode

• Before installing the burner in the appliance, inspect the flame rod

and electrode.

• Verify the dimensions shown in this page.

• If the flame rod or electrode is damaged or not in the correct position,

follow the procedure below to access and adjust.

To access the flame rod or electrode

1. If the burner is not installed in an appliance, you can inspect the flame

rod and electrode from the front of the burner. To change the position

of the flame rod or electrode, you must remove the combustion head/

gas manifold assembly from the burner. See “D” thru “H” below.

2. To remove the combustion head/gas manifold assembly, you must

disconnect the gas piping and swing the burner flange door open.

See Figure 4, and proceed to:

a. Turn off all power to the burner and appliance before proceeding.

b. Close the manual gas valve on the gas supply line.

c. Disconnect the burner gas train union.

d. Remove the gas pipe at the burner air tube.

e. Remove the four nuts securing the burner hinged door flange.

f. Swing the burner open at the door flange.

g. Remove the two screws holding the gas manifold saddle to the air tube.

(Save the gasket.)

h. Disconnect electrode and flame rod wires then slide the burner combus-

tion head/gas manifold assembly out the end of the open air tube.

3. Position Electrode first — Make sure the electrode is placed according

to the dimensions shown in Figure 6. To adjust the electrode, loosen

the electrode clamp screw and slide/rotate into position.

Tighten the electrode clamp screw after positioning. The shim rod

welded in the clamp’s v-groove aligns the bracket when tightening.

4. Position Flame rod after setting electrode — Make sure the flame

rod is located as shown in Figure 7. To adjust, loosen the flame rod

clamp screw. Tighten the screw to secure the flame rod in place.

5. Replace the combustion head/manifold in the air tube.

Figure 6

Electrode location

Figure 7

Flame rod location

After electrode is adjusted, use

a 1/8” drill bit to check electrode

spacing to surface per Figure

6. Also use the drill bit to make

sure the electrode is no closer

than 1/8” to any other metal

surface.