Model 702G/O Advanced gas/oil burners — Instruction manual

Carlin part number MN702GO Rev. 06/23/14

– 25 –

Where appliance instructions differ from this manual, follow the appliance instructions.

Step 6

(firing on gas)

Set butterfly gas valve linkage

1.

Switch the low-fire switch to low fire.

2.

Check CO

2

and CO. The CO

2

should be between 9.0% and 10.0% (natural

gas) or between 10.0% and 11.2% (propane); with CO less than 100 PPM.

3.

To adjust the low-fire air (change CO

2

), move the burner fuel selector

switch to OFF. Adjust the butterfly gas valve linkage as described in

the following to change the low-fire gas flow to the burner head. Do not

change the main gas pressure regulator setting.

4.

DO NOT ADJUST THE LOW-FIRE AIR DAMPER SETTING. This must

be left as set for oil firing.

5.

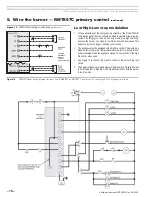

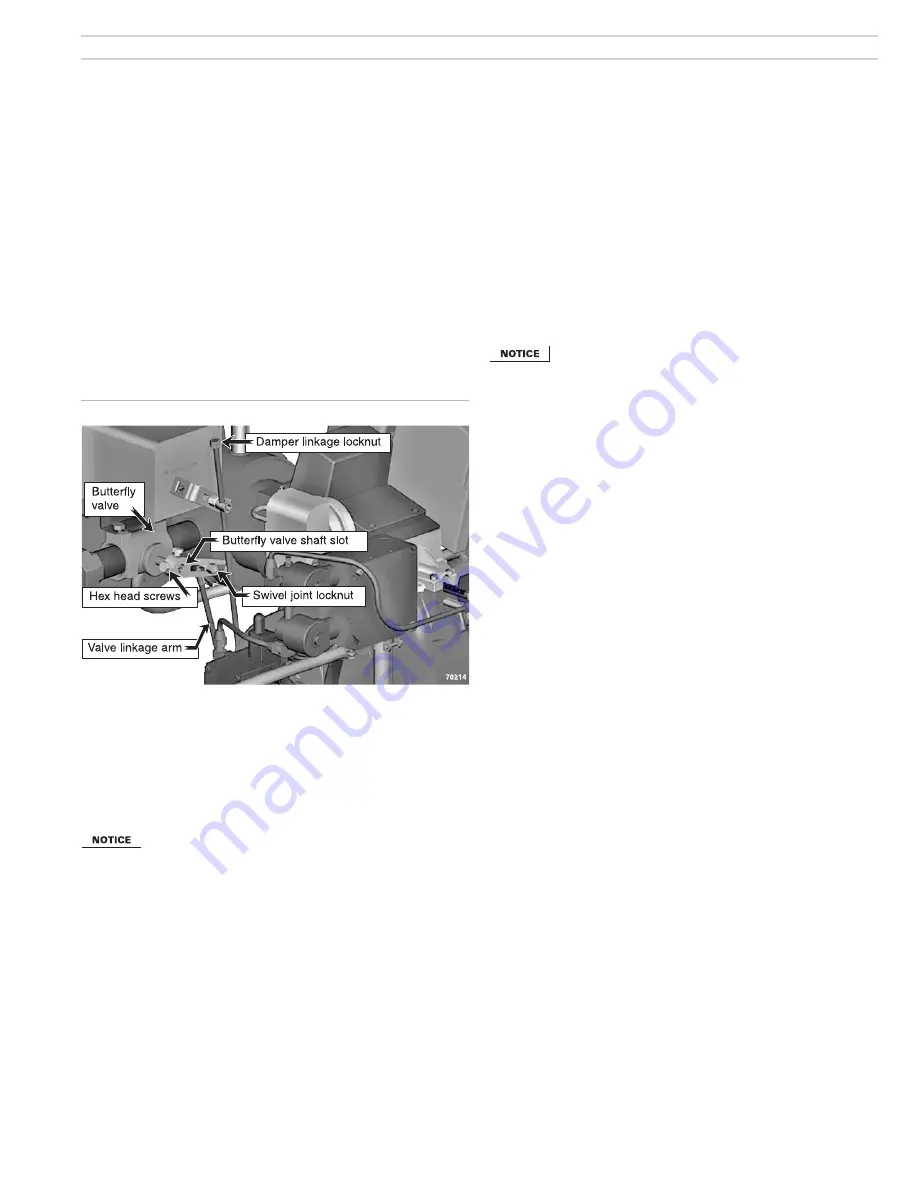

See Figure 18 for location of linkage components.

Figure 18

Butterfly gas valve linkage

6.

Raise the damper motor linkage by pulling up on the damper linkage

locknut and hold in this position.

7.

Loosen the two hex head screws on the butterfly valve linkage arm boss.

Then lower the damper linkage to the low fire position with the damper

linkage locknut. Release the locknut.

8.

Mark the position of the butterfly valve linkage arm swivel joint locknut

with a pencil or felt-tip pen. Then loosen the swivel joint locknut.

To adjust the linkage, move the swivel joint locknut in small

increments. A 1/8-inch move can cause CO

2

to change as

much as 1.5%.

•

If more gas is needed (to increase CO

2

), move the swivel joint to the RIGHT.

•

If less gas is needed (to decrease CO

2,

), move the swivel joint to the LEFT.

9.

Tighten the swivel joint in place.

10.

Raise the damper motor linkage by pulling up on the damper linkage

locknut and hold in this position. The butterfly valve shaft slot must

be horizontal. If not, use a common-bit screwdriver to rotate the valve

slot to horizontal.

8. Adjust the burner using test instruments

(continued)

11.

Tighten the two hex head screws on the butterfly valve linkage arm boss.

Then lower the damper motor linkage to the low fire position.

12.

Restart and repeat as necessary until CO

2

and CO are acceptable.

FOR MASS CODE, PROCEED TO STEP 6A

Step 6a

(firing on oil and on gas)

Verify operation

Perform all of the checkout procedures given in Step 6 of

the burner manual. In addition, verify operation of the gas

pressure switches as described below.

Verify high gas pressure switch operation

❏

Cycle the burner off with the appliance controls and turn off power to the

appliance/burner.

❏

Attach a manometer to the manifold-side manual gas valve test port.

❏

Turn on power and cycle the burner on with the appliance controls.

❏

Measure the manifold gas pressure with the manometer.

❏

Set the high gas pressure switch to a pressure less than actual manifold

pressure. The high gas pressure switch should shut the burner down.

Replace the switch if necessary.

❏

Turn off power to the appliance/burner; remove the manometer and replace

the plug in the gas valve test port. Reset switch.

Verify low gas pressure switch operation

❏

Cycle the burner off with the appliance controls and turn off power to the

appliance/burner.

❏

Close the main manual gas valve.

❏

Cycle the burner on.

❏

The low gas pressure switch should shut the burner down. Replace the

switch if necessary.

❏

Turn off power to the appliance/burner.

❏

Open the main manual gas valve.

❏

Reset low gas pressure switch.