Model 702G/O Advanced gas/oil burners — Instruction manual

Carlin part number MN702GO Rev. 06/23/14

– 7 –

Where appliance instructions differ from this manual, follow the appliance instructions.

2. Prepare site • assemble burner • mount burner

(continued)

Combustion air/ventilation openings

Sizing air openings

Follow all applicable codes and the appliance instruction manual (when

available) to size combustion air openings. Use the following guidelines

when appliance instructions are not available.

•

All air from inside building (building must be well-ventilated):

Size air openings for a free area (after louver deduction) of at least 1

square inch per 1,000 Btuh input of all appliances in the space.

•

All air through openings directly from outside the building through an

adjacent outside wall:

If air openings connect directly to outside, provide two openings, one

within 12 inches of the ceiling, the other within 12 inches of the floor.

Each opening must have a free area (after louver deduction) of:

•

If directly through side wall: 1 square inch for each 4,000 Btuh of all

appliances in the space.

•

If through vertical ducts: 1 square inch for each 4,000 Btuh of all appli-

ances in the space.

•

If through horizontal ducts: 1 square inch for each 2,000 Btuh of all ap-

pliances in the space.

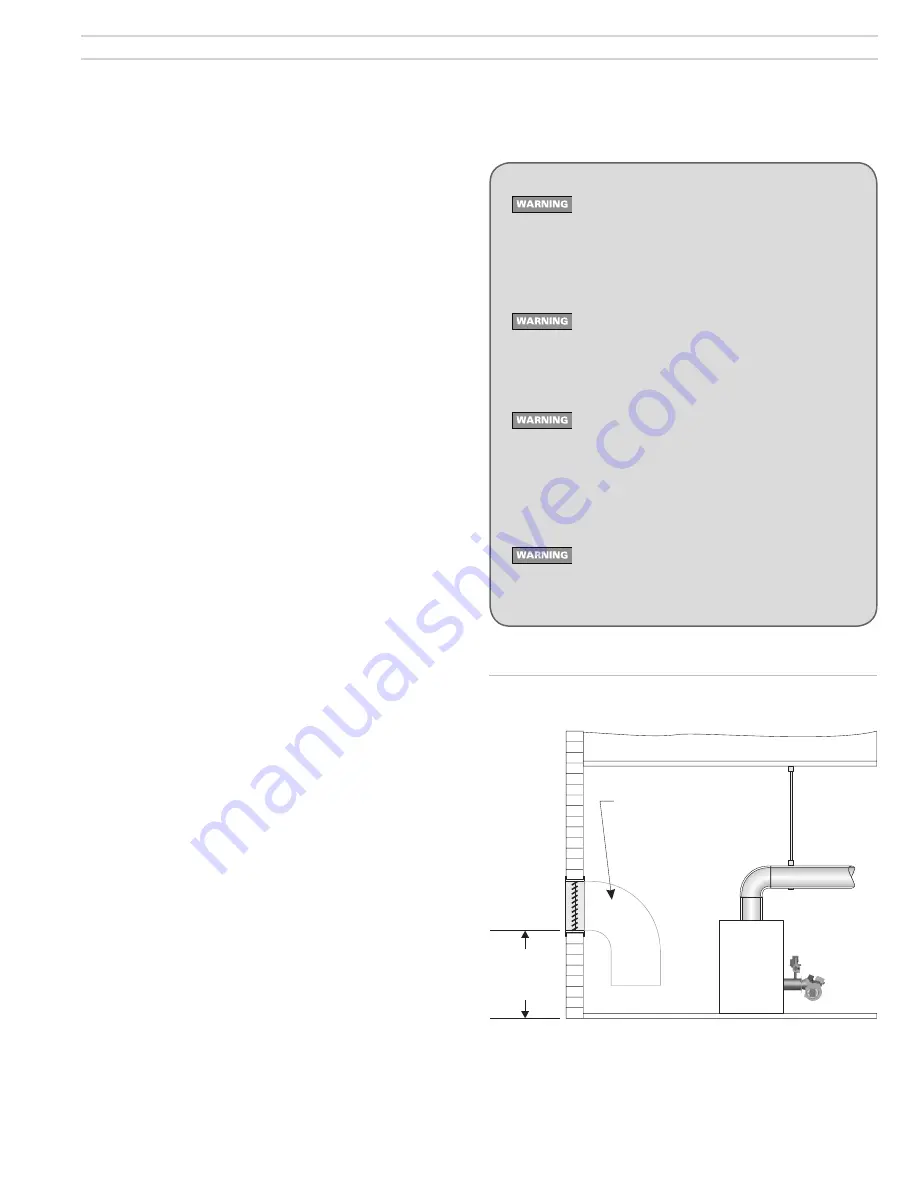

Locating air openings

Follow all applicable codes and the appliance instruction manual (when

available) to size combustion air openings. Refer to Figure 2 when ap-

pliance instructions are not available.

Estimating free area

When specific information on the free area of louvers is not available,

estimate free area as follows:

1.

Wood louvers — free area = area times 0.25.

2.

Metal louvers or grilles — free area = area times 0.60.

3.

Screens, when used must be no smaller than ¼ inch mesh.

Motorized vent dampers

Wire the vent damper end switch to prevent operation of the burner until

the air opening louvers are fully open.

Combustion air/ventilation opening checklist

•

Verify that air openings are unobstructed.

•

Verify that appliance space and air source spaces are free of:

•

Gasoline or other flammable liquids or vapors.

•

Combustible materials.

•

Air contaminants, such as laundry products, paint, thinner, varnish, etc.

•

Confirm with user that the area will be kept free of these materials at

all times.

Figure 2

Locating combustion air/ventilation openings

Appliance

Minimum

24 inches above

grade or snow line

Air opening

Where air opening is high on the wall,

duct to within 12 inches of the floor

Installing the burner/appliance in a space that does

not provide enough air for combustion and ventila-

tion can result in severe personal injury, death or

substantial property damage. Follow all applicable

codes and guidelines below to ensure space has

sufficient air openings.

Exhaust fans and negative pressure conditions

— Isolate the boiler room from areas subject to

negative pressure. Size combustion air openings

to ensure neutral air pressure in the boiler room

whenever the burner operates.

Make sure the space provides enough ventilation

to prevent overheating of the appliance, burner and

controls. If there is risk of overheating, you must

install ventilation air openings sized large enough

to provide air for cooling the equipment. Failure to

provide ventilation can result in severe personal

injury, death or substantial property damage.

The space and combustion air supply must not

contain corrosive contaminants, such as laundry

products, paints, varnishes or other chemicals.