EN

TYPICAL START-UP SEQUENCE

TYPICAL SETTING

1. There is no air used by this spray gun to influence atomisation and fan pattern size.The fluid pressure and

selection of spray tip controls these spray parameters.

2. Select a suitable spray tip based upon the information contained in the tables on page 11 and 12 and fit it

securely onto the spray gun.

3. There is limited control of fluid flow using pump pressure and tip orifice size.

1. Select a nominal gun fluid inlet pressure to start the spray optimisation [eg 500psi/33 bar] by adjusting pump

pressure or fluid regulator output pressure

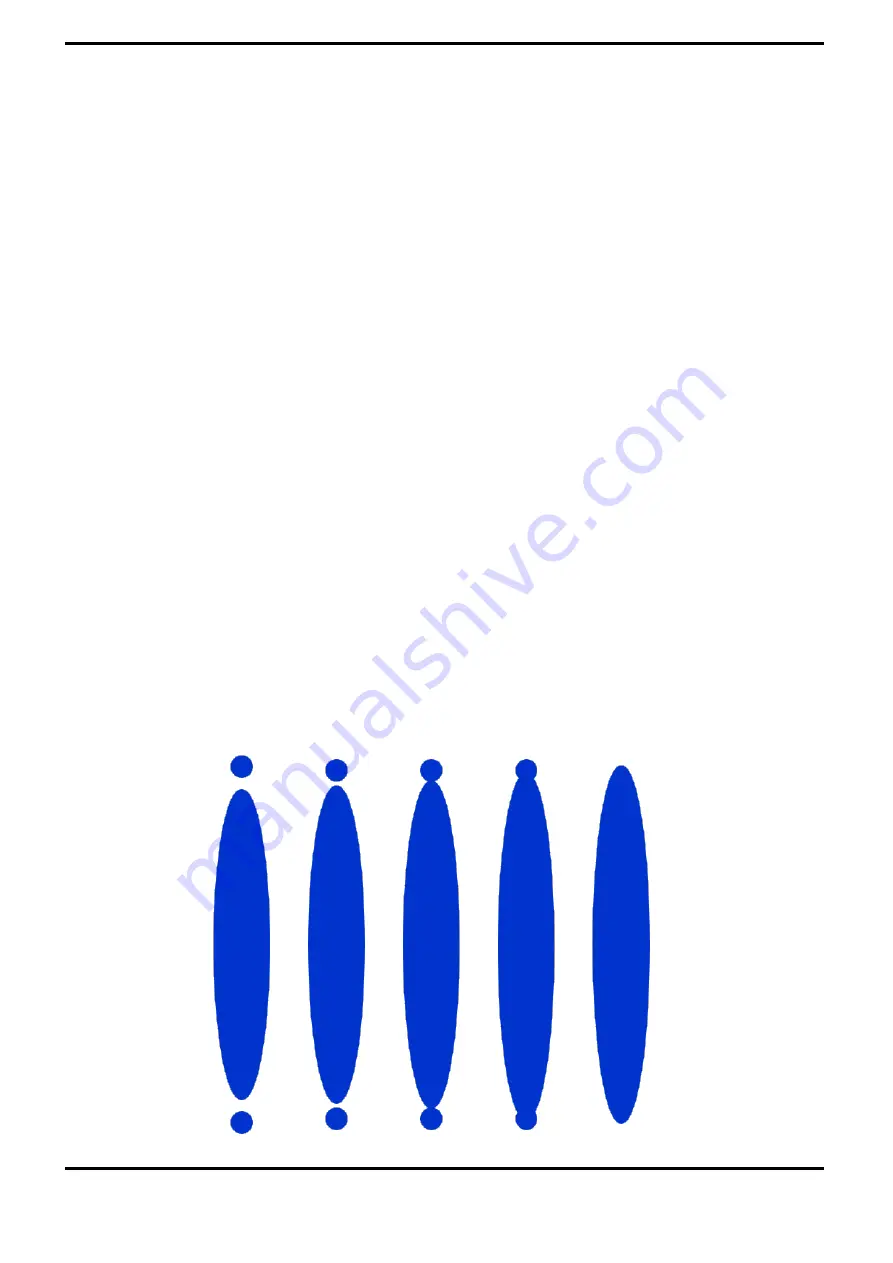

2. View the spray pattern appearance and increase or decrease fluid pressure to establish the minimum fluid

pressure at which a well shaped spray pattern can be achieved without poor atomisation 'tails' .

3. Test spray products and increase fluid pressure until the required results are achieved.

4. If maximum fluid pressure is reached and more fluid flow is required, then increase tip orifice size and repeat

steps 1-3

5. Remember - To change fluid flow, coating thickness, spray pattern length etc could require modification of

fluid viscosity, tip orifice size, tip pattern angle, pump pressure and gun traverse speed

SB-E-2-646 R1.1

13/28

www.carlisleft.com

Summary of Contents for Binks AG360 Series

Page 10: ...EN SPRAY GUN AND MANIFOLD INSTALLATION SB E 2 646 R1 1 10 28 www carlisleft com ...

Page 11: ...EN EXPLODED VIEW SB E 2 646 R1 1 11 28 www carlisleft com ...

Page 16: ...EN DISASSEMBLY NEEDLE PACKING SB E 2 646 R1 1 16 28 www carlisleft com ...

Page 23: ...EN FIXING LOCATIONS SB E 2 646 R1 1 23 28 www carlisleft com ...

Page 24: ...EN DIMENSIONS SB E 2 646 R1 1 24 28 www carlisleft com ...

Page 26: ...EN NOTES SB E 2 646 R1 1 26 28 www carlisleft com ...

Page 27: ...EN NOTES SB E 2 646 R1 1 27 28 www carlisleft com ...