EN

www.carlisleft.com

77

-

3345 R1.1 (06/2022)

53 / 62

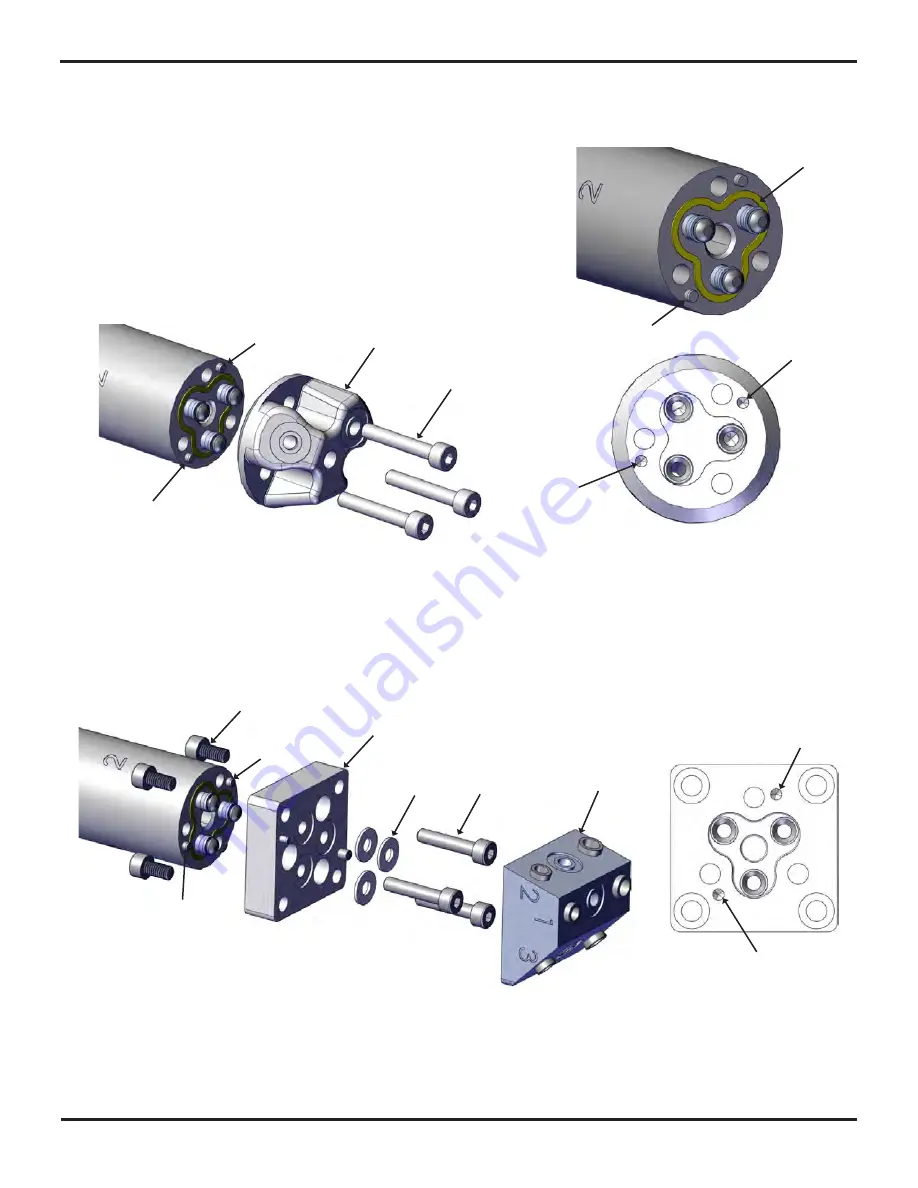

6. Assembly instructions:

Place the nozzle head seal (1) in its groove at the top of the central

body extension.

Guide the round nozzle head (2) to its correct position using the

pins (3) and corresponding holes (4) then fasten the nozzle head

with three screws (5).

For the square adapter (6), guide it using the pins (3) and corresponding holes in the adapter (7). The

adapter is then fastened to the central body with three screws (8). After placing the seals (9) in place a

nozzle head (10) can be attached to the square adapter (6) using four screws (11).

1

4

4

5

[3.3 Nm]

2

3

3

3

6

8

[3.3 Nm]

9

10

11

[3.3 Nm]

3

7

7

3