4

TROUBLESHOOTING

Problem

Cause

Correction

Will not spray

No air or material is supplied to the gun.

CHEATER VALVE ASSY (15) nob is not properly adjusted.

NEEDLE ADJUSTING SCREW (12) is not properly adjusted.

Check air and material lines.

Adjust accordingly.

Adjust accordingly.

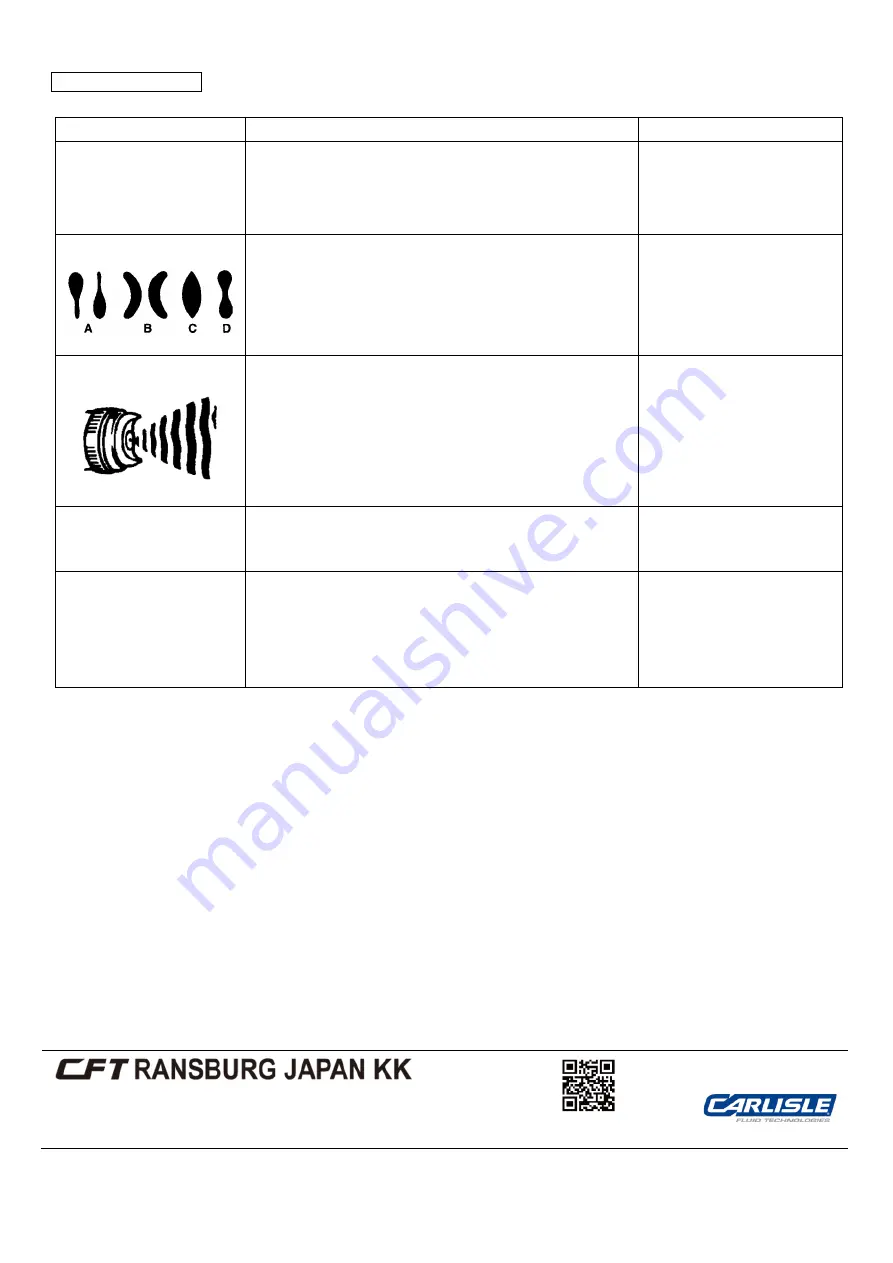

Improper spray pattern

A, B: Material build-up on the AIR CAP (2) or FLUID TIP (3-1).

A, B: AIR CAP (2) or FLUID TIP (3-1) damaged.

C, D: Incorrect fluid delivery or viscosity.

C, D: Incorrect air pressure.

Clean the AIR CAP or FLUID TIP.

Replace.

Adjust fluid delivery and viscosity.

Adjust air pressure.

Intermittent or fluttering spray

Insufficient material in the cup or loose Connector.

Partially obstructed fluid passage or hose.

Loose FLUID TIP (3-1).

Material build-up on the seating on FLUID TIP (3-1) and GUN BODY (7).

Damaged FLUID TIP (3-1).

Fill material or tighten the Connector.

Clean or replace.

Tighten.

Clean.

Replace.

Fluid leaking from

NEEDLE PACKING ASSY (13)

Worn or damaged NEEDLE PACKING ASSY (13).

Worn or damaged NEEDLE (3-2).

Replace.

Replace.

Dripping from FLUID TIP (3-1)

Material build-up on the seating on FLUID TIP (3-1) and NEEDLE (3-2).

Worn or damaged FLUID TIP (3-1) or NEEDLE (3-2).

NEEDLE PACKING ASSY (13) and NEEDLE (3-2) are stuck together.

Loose NEEDLE ADJUST SCREW (12).

Clean.

Replace.

Clean and lubricate.

Adjust accordingly

.

15-5, Fukuura 1-chome, kanazawa-ku, Yokohama, Kanagawa Japan 236-0004

TEL : +81-45-785-6434 FAX : +81-45-785-6517

http://www.carlisleft.co.jp

©2020 Carlisle Fluid Technologies

®DEVILBISS is a registered trademark of Carlisle Fluid Technologies.

JCK_E01_21.10