EN

Loose fluid nozzle.

Partially obstructed fluid passage or

hose.

Pattern adjustment valve set too low.

Tighten.

Paint or coating too thick.

Too high horn pressure.

Clean or replace.

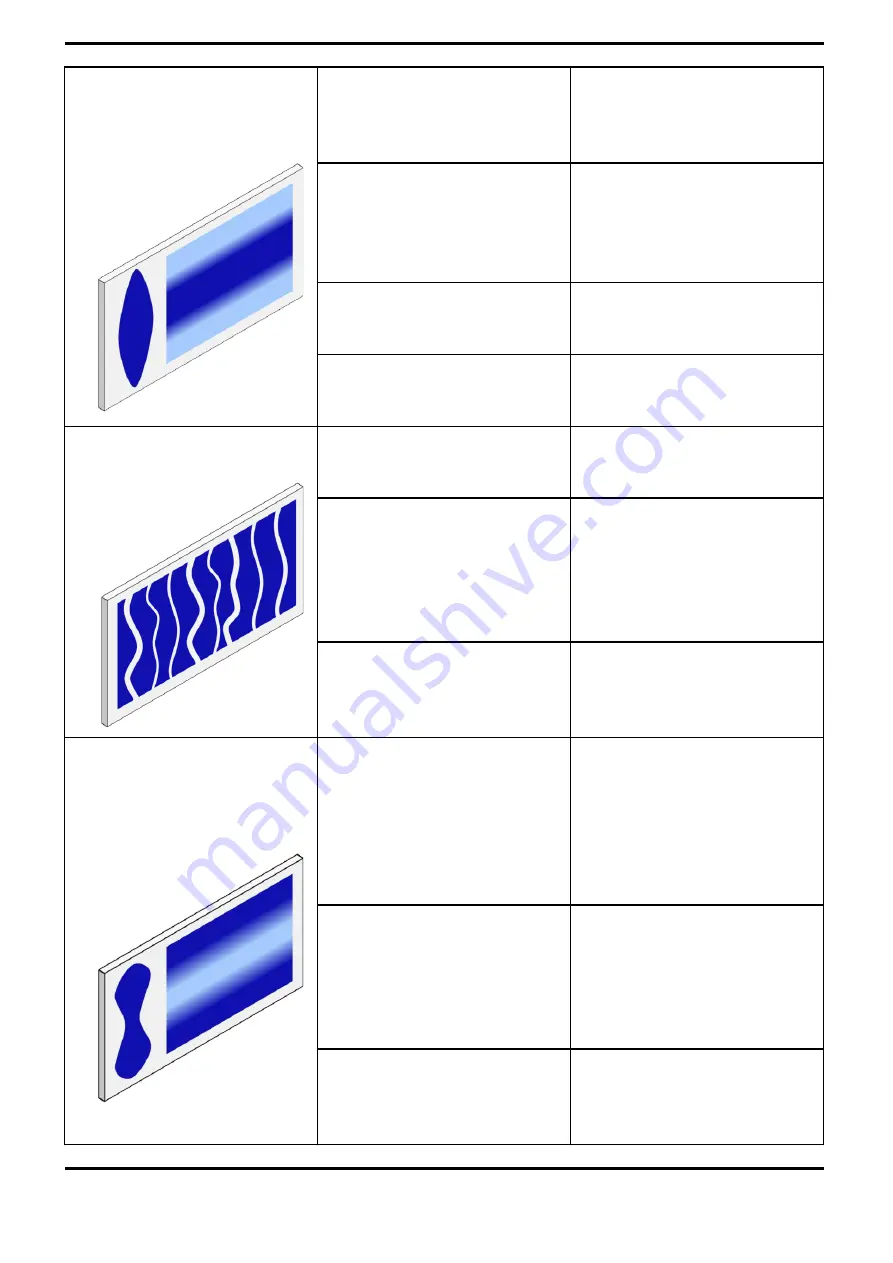

Split spray pattern

Not enough paint or coating flow.

Intermittent or 'fluttering'

spray fan.

Turn out counter clockwise to

achieve correct pattern.

Increase air pressure.

Reduce air pressure by rotating

pattern control valve clockwise.

Fluid nozzle not seated correctly in

gun head.

Remove fluid nozzle, clean

components, check cone seating on

tip and gun for damage or

contamination.

Increase fluid flow by changing fluid

nozzle size, opening needle control

knob or increase fluid pressure on

pressure feed container.

Thin to correct consistency.

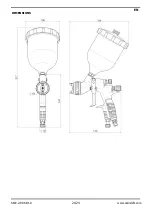

Heavy centre pattern.

Reduce fluid flow by turning fluid

needle adjusting screw clockwise.

Reduce fluid pressure.

Reduce input air pressure.

Too much air for fluid quanitity used.

Too much paint or coating.

Atomizing air pressure too low.

SB-E-2-996 R1.0

19/24

www.carlisleft.com

Summary of Contents for DeVILBISS 905038

Page 5: ...EN EXPLODED VIEW SB E 2 996 R1 0 5 24 www carlisleft com ...

Page 12: ...EN DISASSEMBLY PACKING DISASSEMBLY AIR VALVE SB E 2 996 R1 0 12 24 www carlisleft com ...

Page 13: ...EN ASSEMBLY AIR VALVE SEALS SB E 2 996 R1 0 13 24 www carlisleft com ...

Page 14: ...EN SPREADER VALVE REPLACEMENT SB E 2 996 R1 0 14 24 www carlisleft com ...

Page 21: ...EN DIMENSIONS SB E 2 996 R1 0 21 24 www carlisleft com ...

Page 22: ...EN NOTES SB E 2 996 R1 0 22 24 www carlisleft com ...

Page 23: ...EN NOTES SB E 2 996 R1 0 23 24 www carlisleft com ...