2

Specifications are subject to change without notice (09.06.2021)

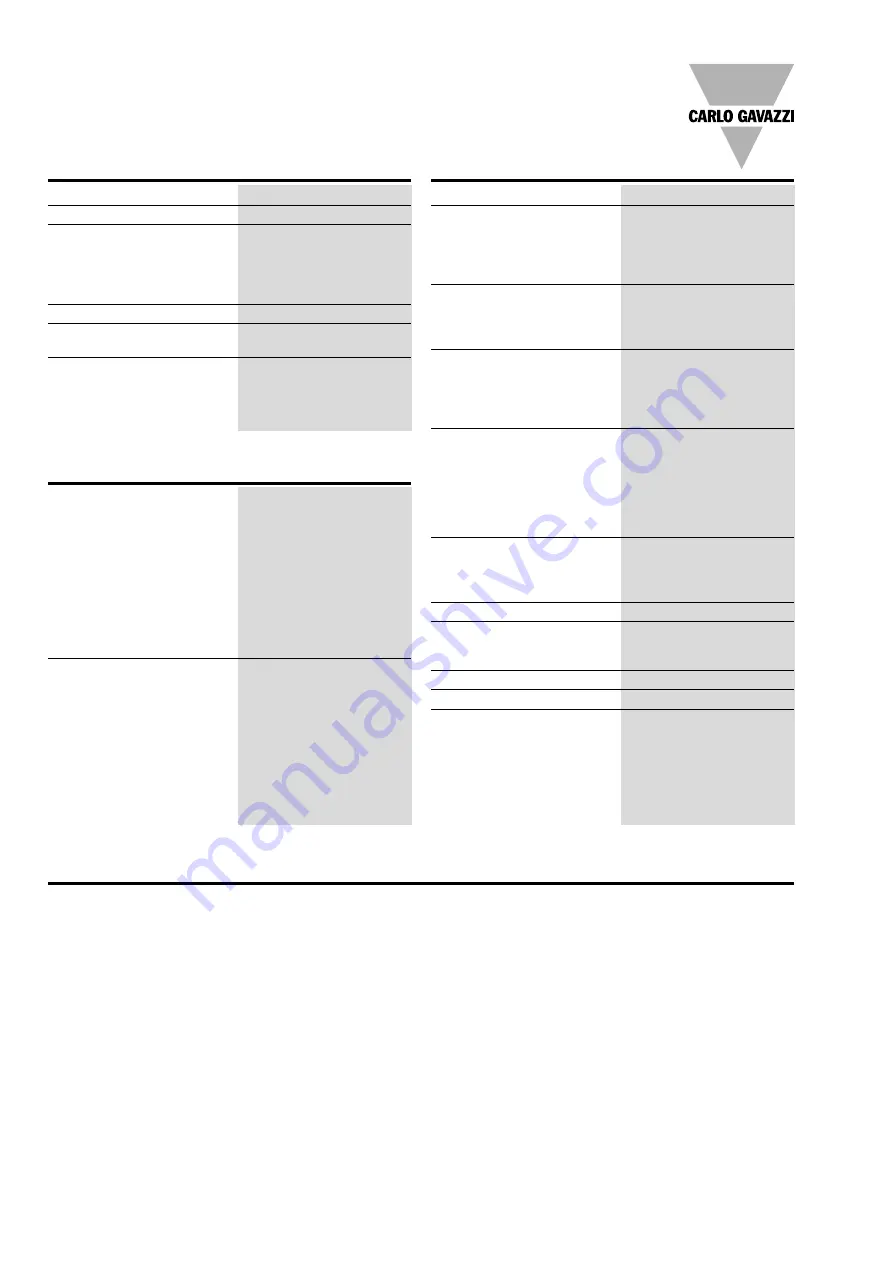

DWB03, PWB03

Supply Specifications

General Specifications

Power supply

Overvoltage cat. III

Rated operational voltage

(IEC 60664, IEC 60038)

Through terminals:

DWB03:

L1, L2, L3

PWB03:

5, 6, 7

M23

177 to 276 VAC 45 to 65 Hz

DWB03CM48

323 to 552 VAC 45 to 65 Hz

PWB03CM48

323 to 477 VAC 45 to 65 Hz

DWB03CM69

510 to 793 VAC 45 to 65 Hz

Dielectric voltage supply

to output

4 kV

Rated operational power

M23

9 VA @ 230 V, 50 Hz

M48

13 VA @ 400 V, 50 Hz

M69

21 VA @ 600 V, 50 Hz

Supplied by

L1 and L2

Power ON delay

1 to 30 s ± 0.5 s

Reaction time

(input signal variation from

-20% to +20% or from

+20% to -20% of set value)

Alarm ON delay

< 250 ms

Alarm OFF delay

< 250 ms

Accuracy

(15 min warm-up time)

Temperature drift

± 1000 ppm/°C

Delay ON alarm

± 10% on set value ± 50 ms

Repeatability

± 0.5% on full-scale

Indication for

Power supply ON

LED, green

Alarm ON

LED, red (flashing 2 Hz

during delay time)

Output relay ON

LED, yellow

Environment

Degree of protection

IP 20

Pollution degree

3 (DWB03), 2 (PWB03)

Operating temperature

@ Max. voltage, 50 Hz

-20 to +60°C, R.H. < 95%

@ Max. voltage, 60 Hz

-20 to +50°C, R.H. < 95%

Storage temperature

-30 to +80°C, R.H. < 95%

Housing

Dimensions

DWB03

45 x 80 x 99.5 mm

PWB03

36 x 80 x 94 mm

Material

PA66 or Noryl

Weight

Approx. 250 g

Screw terminals

Tightening torque

Max. 0.5 Nm

acc. to IEC 60947

Product standard

EN 60255-6

Approvals

UL, CSA

CE Marking

L.V. Directive 2006/95/EC

EMC Directive 2004/108/EC

EMC

Immunity

According to EN 60255-26

According to EN 61000-6-2

Emissions

According to EN 60255-26

According to EN 61000-6-3

Mode of Operation

DWB03 and PWB03 meas-

ure the active power of a

3-phase balanced system.

The relay has an adjustable

power ON delay in order to

avoid undesired overload

detection during motor start.

Example 1

Latching mode, relay NE.

In this application DWB03

or PWB03 is connected to

an external current metering

transformer, type MI..., (con-

nected between U1 & U2) as

well as to a 3-phase asyn-

chronous motor. The relay

is energized as soon as the

power supply is applied.

After the power ON delay,

the unit starts to meas-

ure power. If it is within the

setpoints, the relay is ener-

gized, and the yellow LED is

ON. As soon as the power

drops below the lower set-

point or raises above the

upper setpoint the output

relay releases after the set

time has expired. To restart

the measurement, connect

Z1 and U1 (2 and 9) or inter-

rupt the power supply for at

least 1 s.

Example 2

Latching mode, relay NE.

Monitoring the correct

power flow of a generator.

DWB03 and PWB03 react

as described in the pre-

vious example 1. Setting

underpower setpoint at 0

allows to protect the gener-

ator both from overload and

from becoming a motor (i.e.;

supplied by other devices

in the system) allowing, for

example, to disconnect it in

such an event.

Example 3

Start/stop mode, relay NE.

In this application DWB03

or PWB03 are directly con-

nected to a 3-phase asyn-

chronous motor. The relay

is energized as soon as the

power supply is applied

and the start/stop contact

is closed. After the power

ON delay, the unit starts to

measure the active power. If

it is within the setpoints the

relay is energized. As soon

as the power drops below

the lower setpoint or raises

above the upper setpoint

Output Specifications

Output

SPDT relay

Rated insulation voltage

250 VAC

Contact ratings

µ

Resistive loads

AC 1

8 A @ 250 VAC

DC 12

5 A @ 24 VDC

Small inductive loads AC 15

2.5 A @ 250 VAC

DC 13

2.5 A @ 24 VDC

Mechanical life

≥ 30 x 10

6

operations

Electrical life

≥ 50 x 10

3

operations

(at 8 A, 250 V, cos

j

= 1)

Dielectric strength

Dielectric voltage

≥ 2 kVAC (rms)

Rated impulse withstand volt. 4 kV (1.2/50 µs)