OPERATION

1.

CAUTION! Check that the fan inlet/ductwork/exhaust openings are clean and free of obstructions. Poor inlet con-

ditions will result in seriously reduced fan performance.

2.

WARNING! This fan contains rotating parts. Appropriate safety precautions should be taken during operation.

3. Operate under power and check for correct wheel rotation direction (clockwise when looking at top of the wheel).

4.

CAUTION! Incorrect rotation can damage the fan motor and seriously impede fan operation.

MAINTENANCE

1.

DANGER! Before performing and maintenance on the fan, be sure power is turned off and locked in the OFF

position at the service entrance before servicing the fan.

2. Ventilators should be carefully checked at least once a year. For critical or rugged applications, a routine check

every two or three months is suggested.

3. All motors supplied with CARNES ventilators carry a one year warranty from date of shipment. For repairs within

the warranty period, the motor must be taken to the motor manufacturer’s authorized service dealer. Contact your

CARNES representative for additional warranty details.

4. Access to the motor compartment is possible by removing the motor cover or motor cover/motor tube assembly.

5. A periodic motor check should consist of spinning the motor shaft with the power off to be sure the motor turns

freely and the bearings run smoothly. The belt on belt driven units should be removed from the motor sheave.

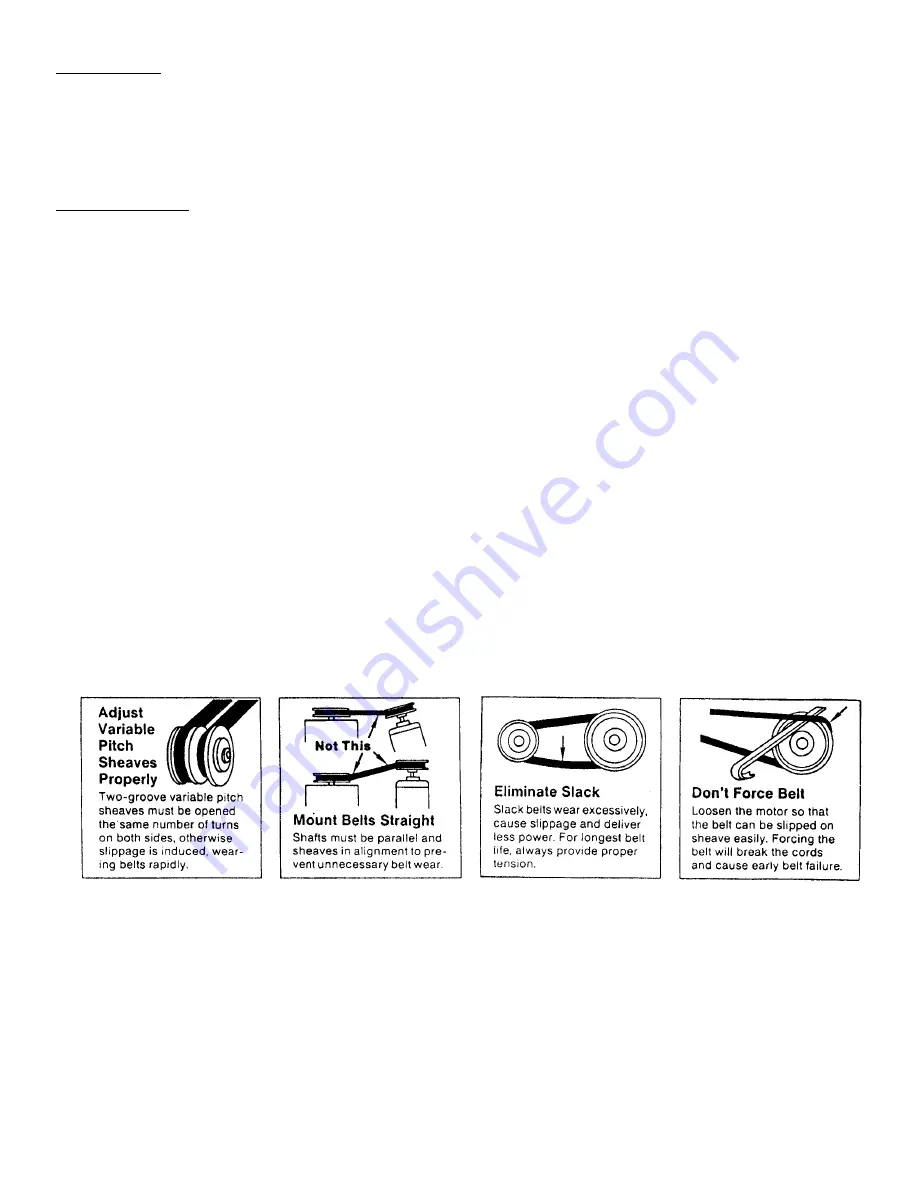

6. CAUTION! When removing or installing a belt, do not force the belt over the sheave. Loosen the motor mount so

that the belt can be easily slipped over the sheave.

7. The belt on belt driven units should be removed and carefully checked for radial cracks, ply separation or irregular

wear. A small irregularity in the contact surface of the belt will result in noisy operation. If any of these defects are

apparent, the belt should be replaced. Check the sheave also for chipping, dents or rough surfaces which could

damage the belt.

8.

CAUTION! The correct belt tension is important. Too tight a belt will result in excess bearing pressure on the

motor bearings and shaft pillow blocks, and may also overload the motor. Too loose a belt will result in slippage

which will quickly “burn” out belts. A belt should feel “live” when thumped, approximately 1/4” belt deflection when

subjected to finger pressure (3 to 5 lbs.) at midpoint between sheaves.

9.

CAUTION! The belt alignment should also be checked to be sure the belt is running perpendicular to the rotating

shafts. Motor and drive shafts must be parallel. Improper alignment will result in excessive belt wear.

10.

CAUTION! Check sheave set screws to ensure tightness. Proper keys must be in keyways.

11.

CAUTION! Do not readjust variable pitch sheave without checking motor amps. Do not readjust variable pitch

sheaves above the maximum catalog RPM for unit and motor. If fixed sheaves are replaced, use only sheaves of

identical size and type.

12.

CAUTION! If adjustment of two groove variable pitch sheaves is required, each sheave must be opened or

closed the same number of turns. Improper adjustment can cause excessive belt wear and premature failure.

2