Carolina Attachments LLC.

Page 17

Swing Boom Cutter

March 2016

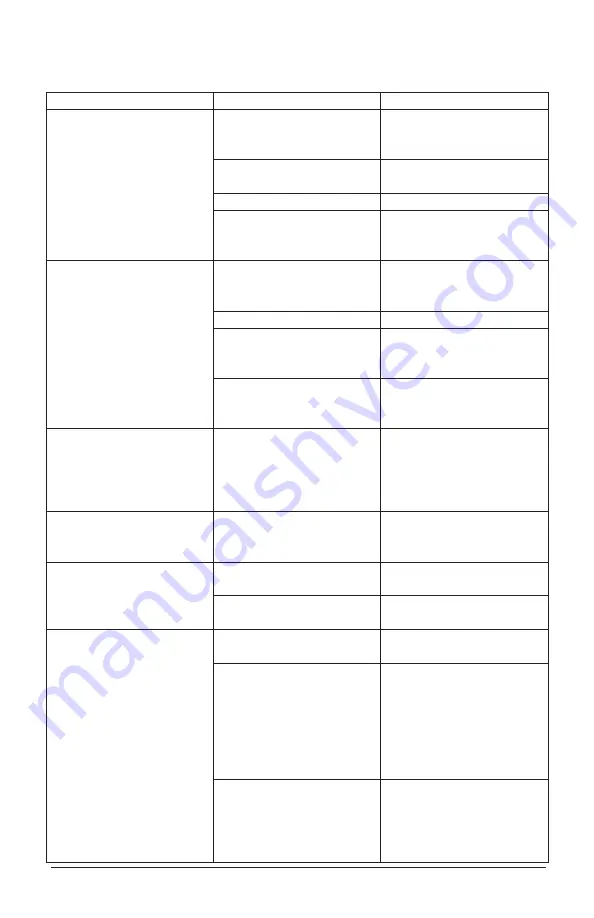

Troubleshooting

Problem

Cause

Resolution

Cutter bogs down

Deck is not properly

leveled & material is

balling under deck

Refer to leveling

instructions found in this

manual.

Dull blades

Remove and sharpen

blades.

Ground speed too fast

Slow down ground speed.

Cutter speed too slow

Raise engine RPMs or

investigate other low oil

flow problem

Vibration felt when

running cutter

Missing, loose, damaged or

unbalanced cutter blades

Replace blades with new or

re-sharpened and equally

balanced blades.

Blade mount damaged

Replace blade mount

Gearbox loose on deck

Tighten & torque gearbox

mounting bolts. Replace

bolts if they are damaged.

Cutting height too low for

cutting in sandy or rocky

soils

Raise cutter height.

Blades get dull too quickly

Blades have contacted

solid objects (rocks, steel

pipes, etc.)

Clear cutting area of solid

objects before hitting

them, or raise the cutter

height to clear exposed

rock surfaces.

Blades breaking

Excessive shock loads

Avoid hitting solid objects

(rock, steel pipes, large

tree stumps, etc.).

Hydraulic oil level goes

down during operation

Leak at valve, cutter motor

or other plumbing

Investigate & repair

Leaks in skid steer

hydraulic system

Investigate & repair

Blades do not spin when

flow is activated

Shear bolt between motor

and gearbox is sheared

Replace with proper shear

bolt specified for this unit.

Motor or gearbox failed

Disconnect the drive chain

between motor & gearbox.

If blade holder can be

turned by hand, motor

failure is suspect. Call the

Factory for further

instructions.

Check valve failure

Remove check valve from

tees, cap the tees and

attempt to run cutter. If

cutter spins, replace the

check valve.