13

12

Model No. C1565 contact us 1-888-666-1887

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

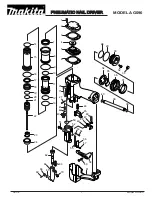

REMOVING NAILS

3.Remove the remainning nails from the

magazine (Fig.F).

1.Disconnect Air hose (Fig.D).

2.Depress the nail feeder and slowly slide

the nail feeder forward (Fig.E).

Fig. D

Fig. F

Fig. E

DANGER!

●

Do not drive nails on top of other nails or with nailer at too steep an angle.

Nails can ricochet and seriously injure someone.

●

In order to avoid double firing or unwanted ejection of a nail due to

bouncing of the nailer, do not push nailer on workpiece to avoid recoil.

Recoil is necessary for proper operation of the nailer.

●

Do not drive nails from both sides of a wall at the same time. Nails can

be driven into and through the wall and hit a person on the opposite side.

●

Never drive nails into thin boards or near corners and edges of workpiece.

Nails can be driven through or away from workpiece resulting in serious or

life threatening injury.

●

Never use a nailer which is defective or operating abnormally.

●

Never use a nailer as hammer.

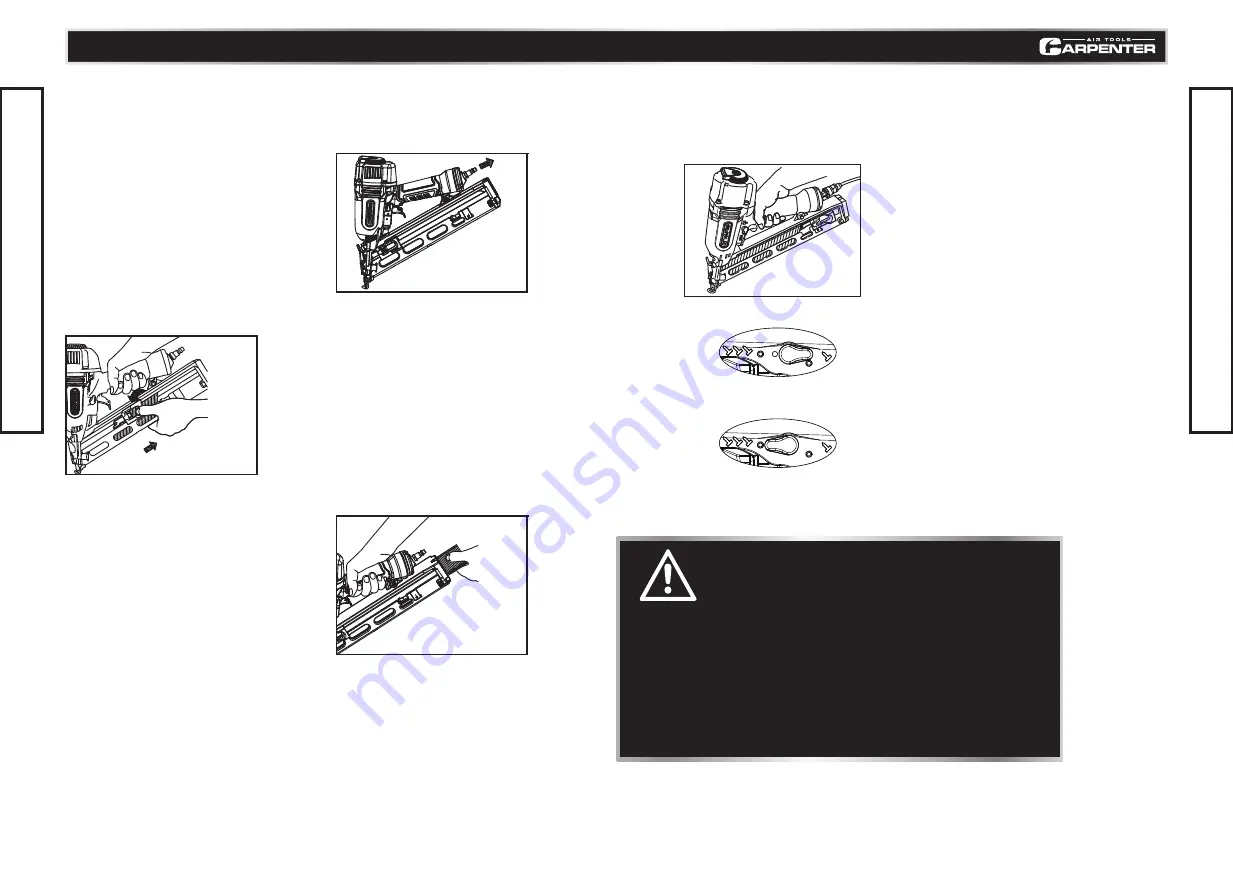

METHOD OF OPERATION

The Carpenter Air-powered Brad Nailer is equipped with a push lever at the nailing point and will not

operate unless the push lever is depressed (pushed upwards)(Fig.G).

Fig. G

①

Single Actuation Mechanism

1.Set the switching device to the position as (Pic I);

2.Make sure the push lever position to the workpiece,Pull the

gunbody and keep the push lever connect to the workpiece and

then press the trigger,It start to work;

3.After the first nails fire,loosen the trigger and raise up the

gunbody,Position the push lever to the workpiece and rework as

above steps.

②

Contact Actuation Mechanism

1.Set the switching device to the position as (Pic II);

2.Press the trigger first and then postition the push lever to the

workpiece,Press the push lever and begin to fire;

3.After the first nails out, hold the trigger tight,and raise up the push

lever,Make sure the push lever postion to the workpiece,and then

press it and rework as above steps.

Pic I

Pic II