15

14

Model No. C1565 contact us 1-888-666-1887

OPERATING INSTRUCTIONS

TROUBLESHOOTING

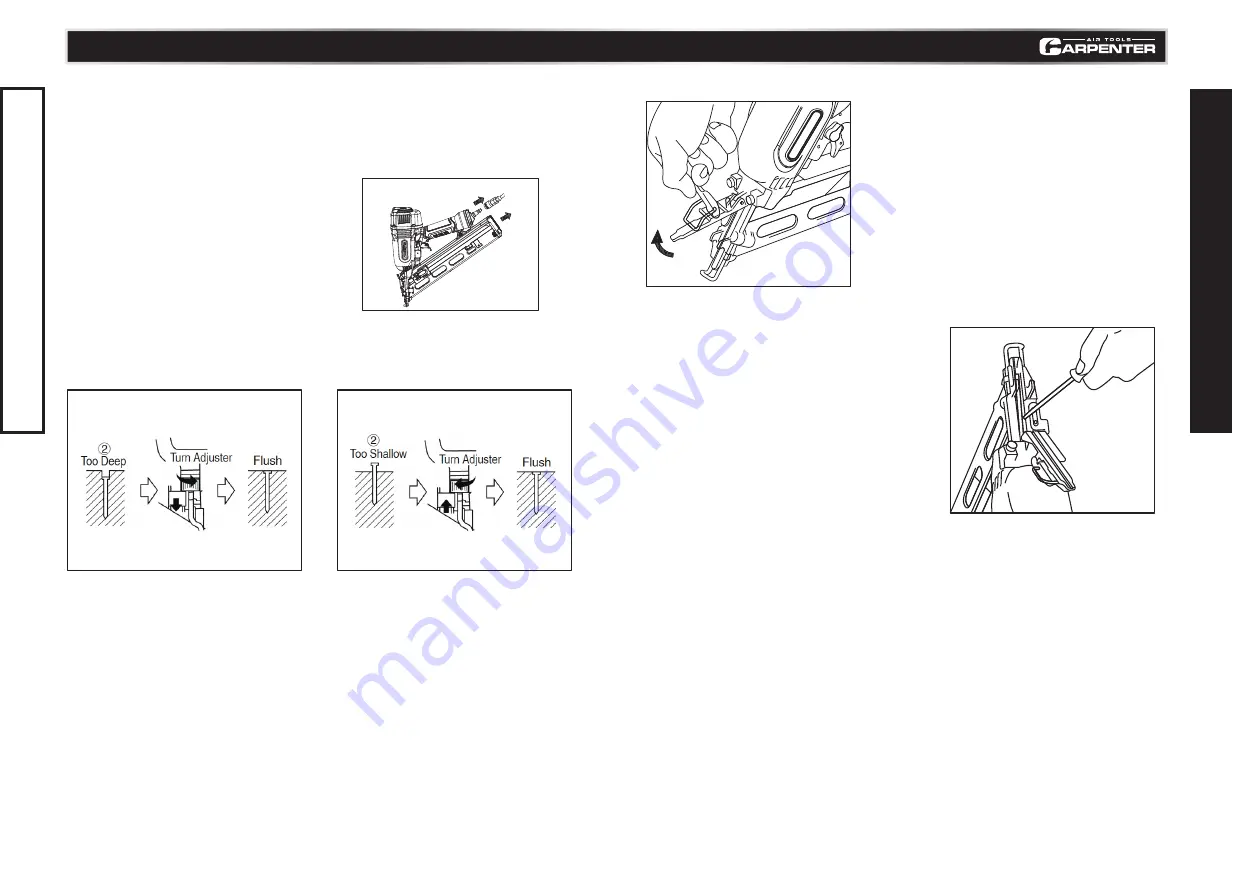

Fig. H

Fig. J

Fig. K

ADJUSTING THE NAILING DEPTH

To assure that each nail penetrates to the same depth, be sure that:

①

The air pressure to the Nailer remains constant (regulator is installed and working properly).

②

The nailer is always held firmly against the workpiece. If nails are driven too deep or too shallow into the

workpiece, adjust the nailing depth using the following instructions.

1

.

Disconnect air hose from nailer (Fig. H).

2a. If the nails are driven too deep, pull the adjuster

downward and turn counter-clockwise (Fig. J).

2b. If nails are driven too shallow, pull the adjuster

downward and turn clockwise (Fig. K).

3. Connect the air hose and perform a nailing test. ALWAYS WEAR EYE PROTECTION.

4. If additional adjustments are necessary, DISCONNECT AIR HOSE FROM NAILER and repeat step 2.

Disconnect air hose

1.Open the guide (Fig.L).

2.Remove the jammed nails with a slotted-head

screwdriver (Fig.M).

Fig. M

Fig. L