19

18

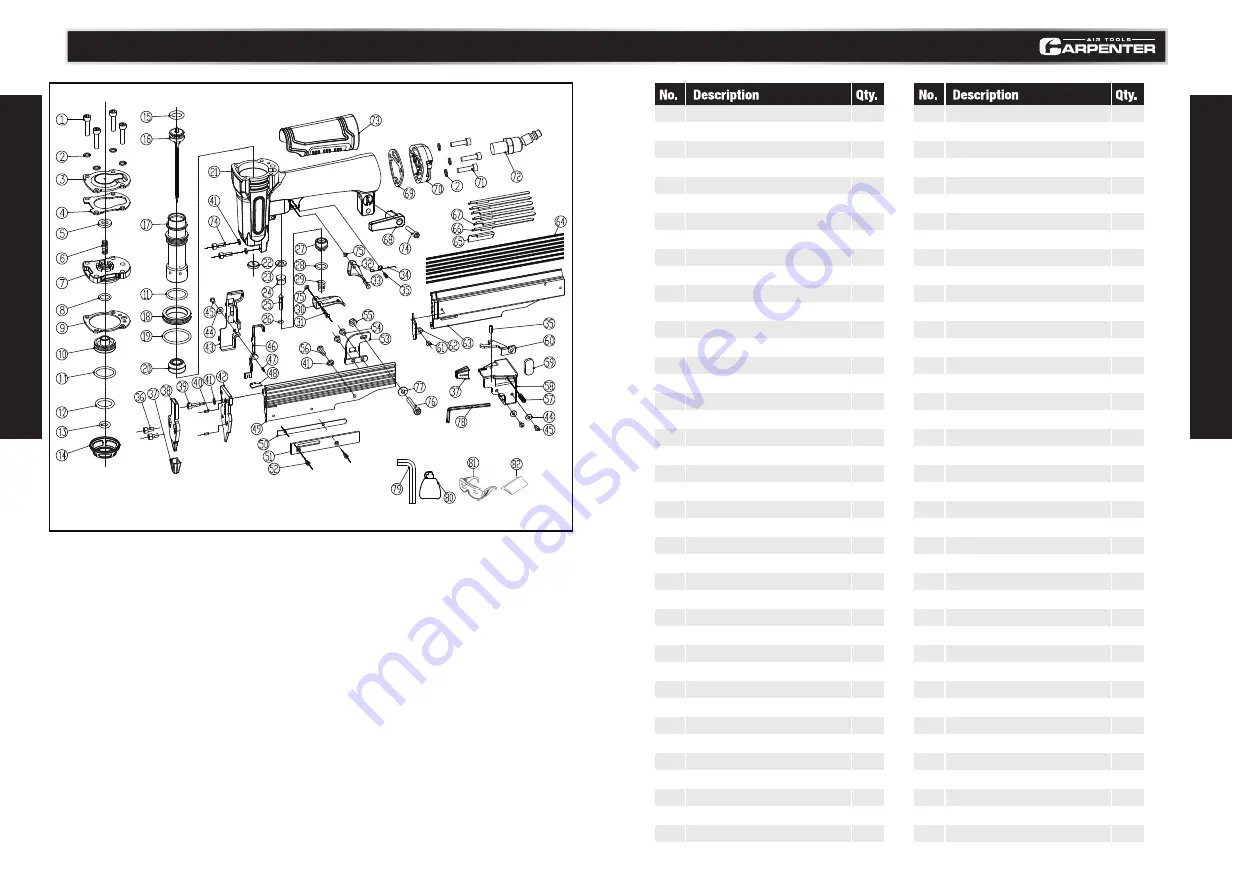

Model No. CP635 contact us 1-888-666-1887

EX

PLOD

ED

V

IE

W

PARTS

LIS

T

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Hex bolt M5X22

Washer 5

Air exhauster

Washer

Washer

Spring

Cylinder head cap

O-ring 11.7X2

Washer

Swtich valve

O-ring 21.8X2.5

O-ring 17.2X3

O-ring 7.6X3

Support collar upper

O-ring 12.2X3

Main piston

Cylinder

Support collar lower

O-ring 30.2X2.65

Bumper

Tool body

Rubber pad

Sealing washer 12.9x7x1.8

Valve bushing

Vale rop

O-ring 1.7X2

Sleeve

O-ring 11.2X2

Trigger spring

Trigger I

Trigger pin 15X3

Trigger II

Trigger pin II 11.3X3

Spring

Roll pin 3X8

Hex bolt M4X8

Muzzle

guider

nut

Roll pin 2.5X5

Washer 4

5

7

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

2

4

42

43

44

45

46

Head

cover

Washer d=3

Hex bolt M3X6

Holder

Spring

Top flat

Fixed magazine

Article guide pin

Pintle plate

Hex bolt M3X6

Fixed seat

Hex bolt M4X6

Hex bolt M5

Hex bolt M4X10

Spring

Retainer

Protective pad

Bolt lever

Hex bolt M3X5

Limit piece

Magazine

Spring

Top A

Top B

Top C

Hook

Washer

End cover

Hex bolt M5X20

1/4 NPT air connector

Handle sleeve

Hex bolt M4X12

Split washer 2.5

Hex bolt M5X25

Washer d=5

Allen wrench M4

Allen wrench M5

Lubricant oiler

Eye protection

Manual

1

1

3

3

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

7

1

4

2

1

1

1

3

1

1

3

2

1

1

1

1

1

1

1

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82