Rev. 04/17/03

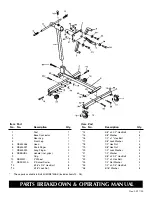

PARTS BREAKDOWN & OPERATING MANUAL

FEATURES

•

Sturdy Tubular Steel Construction for Strength

•

Multi-Position Locking Mount

•

Adjustable Locking Mechanism Allows 360° Rotation

of Engine

•

T-Shaped Design for Added Stability

•

4 Wheel Design

ASSEMBLY INSTRUCTIONS

1.

Bolt front leg (#4) to base connector (#2) using (2)

3/8" x 2-1/2" Hex Bolts (#22), (2) 3/8" washers

(#21), (2) 3/8" lock washers (#20) and (2) 3/8" nuts

(#19). Bolt from outside towards center of

engine stand.

2.

Bolt rear leg (#3) to base connector (#2) using (2)

3/8" x 2-1/2" Hex Bolts (#22),(2) 3/8" washers

(#21), (2) 3/8" lock washers (#20) and (2) 3/8"

nuts (#19).

3.

Insert post (#1) into post tube on base connector

(#2) using a 1/2" x 4" full thread bolt (#25). Screw

into welded nut on post tube, through post (#1)

until tight.

4.

Insert head (#5) into rotator tube on top of post.

Tighten with 1/2" x 1" hex head bolt (#16) screwed

into rotator tube.

5.

Insert handle (#8) through rear of head tube.

6.

Place grips (#9) on both ends of handle.

7.

Attach fingers (#6,7) to head plate using (4) 1/2" x

3" hex head bolts (#23), (4) washers (#24) and (4)

nuts (#18).

INSPECTION

Visual inspection should be made before each use of

the engine stand, checking for damaged, loose or

missing parts. Each stand must be inspected by a

manufacturer’s repair facility immediately, if accidentally

subjected to an abnormal load or shock. Any stand

which appears to be damaged in any way, found to be

badly worn, or operates abnormally

MUST BE

REMOVED FROM SERVICE

until necessary repairs are

made by a manufacturer’s authorized repair facility. It is

recommended that an annual inspection of the stand be

made by a manufacturer’s authorized repair facility and

that any defective parts, decals or warning labels be

replaced with manufacturer’s specified parts.

A list of authorized repair facilities is available from

the manufacturer.

SPECIFICATIONS

Capacity ............................................750 Lbs.

Length ..................................................32-1/2"

Width ....................................................28-/12"

Height ........................................................38"

Shipping Wt...........................................59 lbs.

OPERATING INSTRUCTIONS

Drain oil and coolant and remove flywheel from engine

before mounting. Mount engine as directed in

procedures which follow. Refer to engine service

manuals and technical bulletins when mounting engines.

Lift engine (block) with crane or hoist until even with

head of engine stand. Bolt through adjustable fingers to

back of block at bell housing mounting holes. Fasten

securely to mounting plate. Slowly lower crane or hoist

so that the engine stand supports full weight of engine.

To check engine balance, carefully loosen hex bolt at

back of rotating head, making sure stand is secured

from tipping, and turn handle to rotate engine. If balance

is not satisfactory, rotate engine to its original position

and raise with crane or hoist just enough to take weight

off the stand. Loosen bolts on adjustable fingers and

realign so that weight is evenly distributed. Tighten all

bolts securely and recheck balance. For safe and

secure operation: do not rotate engine more than 90° for

any one location of the positioning handle. In general,

keep the handle within 45° of horizontal. Keep a firm

hold on positioning handle while rotating engine. To

remove an engine from stand, attach a crane or hoist

and raise engine just enough to take engine weight off

stand. Carefully remove bolts attaching fingers to

engine. Be aware that there will be a slight movement of

stand as total engine weight is transferred to crane.

DO NOT CRAWL UNDER ENGINE OR PLACE ANY

PART OF YOUR BODY UNDER ENGINE AT ANY

TIME DURING MOUNTING OF ENGINE, USE OF

STAND, OR REMOVAL OF ENGINE.