1-14

Table 1-3. Safety and Protective Devices

UNSAFE CONDITIONS

SAFETY DEVICES

DEVICE SETTING

1. Excessive current draw

1. Circuit Breaker (CB-1) ---

Manual Reset

1. Trips at 29 amps

(460 VAC)

1. Circuit Breaker (CB-2) ---

Manual Reset

1. Refer to paragraph 1.4.a

2. Excessive current draw on control circuit

2. Fuse (F3)

2. 15 amps

3. Excessive current draw by the controller

3. Fuse (F1 & F2)

3. 5 amps

4. Excessive current draw by

the optional DataCorder

4. Fuse (F)

4. 3 amps

5. Excessive condenser fan motor

winding temperature

5. Internal Protection (IP-CM) ---

Automatic Reset

5. N/A

6. Excessive compressor motor winding

temperature

6. Internal Protector (IP-CP) ---

Automatic Reset

6. N/A

7. Excessive evaporator fan motor(s)

winding temperature

7. Internal Protector(s) (IP-EM) ---

Automatic Reset

7. N/A

8. Abnormal pressures in the high

refrigerant side

8. Fusible Plug

8a. Rupture Disc

8. Refer to section 1.3.i.

8a. Refer to section 1.3.j.

9. Abnormally high discharge pressure

9. High Pressure Switch

9. Opens at 25 kg/cm

@

(350 psig)

10. Excessive evaporator motor

transformer or power (auto)

transformer winding temperature

10. Internal Protector (IP-Trans) ---

Automatic Reset

10. Opens at 178

¦

5

_

C

(350

¦

10

_

F)

Closes at 150

¦

7

_

C

(300

¦

12

_

F)

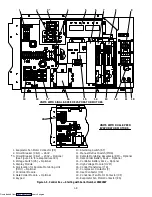

1.7 SAFETY AND PROTECTIVE DEVICES

Unit components are protected from damage by

safety and protective devices listed in Table 1-3. These

devices monitor the unit operating conditions and open a

set of electrical contacts when an unsafe condition

occurs.

Open safety switch contacts of one or more of the

following devices IP-CP, HPS, or IP-Trans (Auto) will shut

down the compressor.

Open safety switch contacts of device IP-CM will shut

down the condenser fan motor.

The entire refrigeration unit will shut down if one of

the following safety devices open: (a) Circuit Breaker(s)

or; (b) Fuse (F3/15A) or; (c) Evaporator Fan Motor

Internal Protector(s) --- (IP-EM).

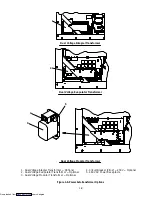

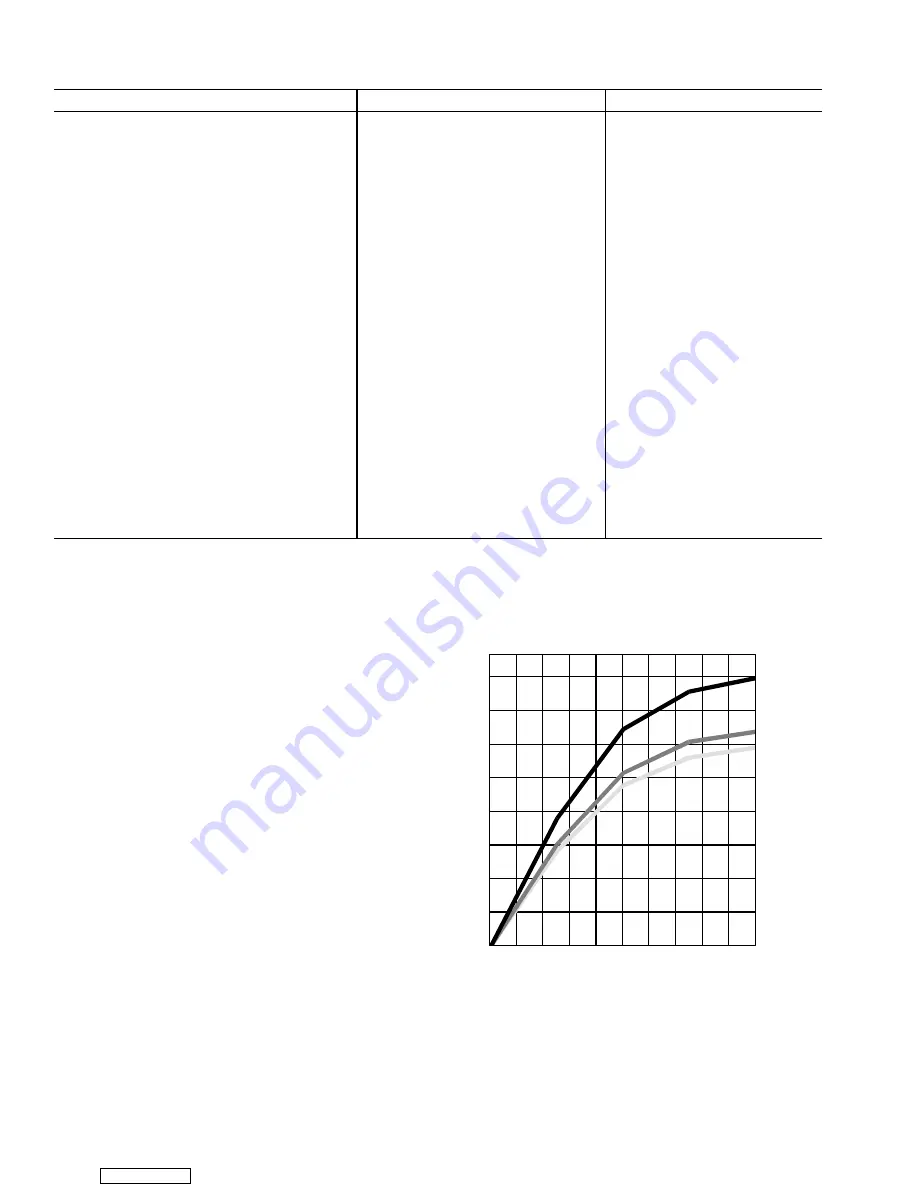

1.8 FRESH AIR MAKEUP VENT

The purpose of the vent is to provide ventilation for

commodities that require fresh air circulation and

must

be closed

when transporting frozen foods.

Air exchange depends on static pressure differential

which will vary depending on the container and how the

container is loaded. The chart above gives air exchange

values for an empty container. Higher values can be

expected for a fully loaded container.

0

30

60

90

120

150

180

210

240

0

10 20 30 40 50 60 70 80 90 100

AIR

FLOW

(CMH)

1-

!

/

2

”

PERCENT OPEN

69NT40 FRESH AIR MAKEUP

T-BAR

2-

%

/

8

”

3”

T-BAR

T-BAR

ZERO EXTERNAL STATIC PRESSURE, 50HZ POWER

For 60HZ operation multiply curves by 1.2

a. Full Open or Closed Positions

Maximum air flow is achieved by loosening the wing

nuts and moving the cover to the maximum open position

(100% position). The closed position is 0% air flow

position.

Downloaded from