1-16

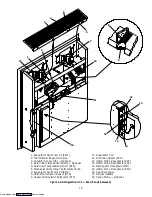

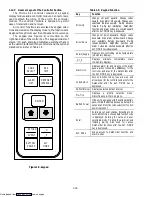

1.12 MICRO-LINK 2 CONTROLLER MODULE

1. Micro-Link 2 Controller Module

2. Battery Pack (Optional)

3. Software Port

4. Connectors

5. Fusess

6. Test Points

7. Control Circuit Power

Connection

8. Status LED

1

2

3

4

5

6

7

4

8

Figure 1-8. Micro-Link 2 Controller Module

1.12.1 Brief Description

WARNING

Do not attempt to service the controller module,

breaking the warranty seal will void the

warranty.

CAUTION

Remove the controller module and unplug all

wire harness connectors before performing any

arc welding on any part of the container.

Do not remove wire harnesses from modules

unless you are grounded to the unit frame with a

static safe wrist strap.

The Carrier Transicold Micro-Link 2 controller is a

custom-designed microprocessor based module which

incorporates electronic logic to:

a. Control supply or return air temperature to extreme-

ly tight limits by providing modulated refrigeration con-

trol, electric heat control and defrost to ensure continu-

ous conditioned air delivery to the load.

b. Provide dual independent readouts of set point and

supply or return air temperatures.

c. Provide digital readout and ability to select data. Re-

fer to Table 1-6 for Controller Function Codes.

d. For controller alarm digital display identification

refer to Table 1-7.

e. Provide a pre-trip step-by-step checkout of refrigera-

tion unit performance, proper component operation,

proper electronic and refrigeration control operation,

proper heater operation, probe calibration and current

limiting. Refer to section 1.13.

f. Provide the ability to select or change Codes 27 to 37

and set point without AC power being hooked up. Refer

to section 1.12.5.

g. The unit provides memory reprogramability and

configuration through a memory card. The memory card

automatically downloads new software to the controller

when inserted, and controls output to the display of status

information.

h. The Status/Power/Executing code LED indicates if

the Controller is powered up and executing code. The

LEDwill be off when power is off. The LED will pulse at a

one second rate if code is being executed.

1.12.2 Controller Programming (Memory) Cards

The programming cards are used for loading soft-

ware into the Controller. This is the same concept as

using a floppy diskette to load software into a personal

computer.

The software that can be loaded into the Controller

module, comes in one of two forms. Either “Operational

Software” or “Configuration Software.”

Operational Software:

This is the software that makes the Controller mod-

ule do what it does. Turn fans on and off, turn compres-

sors on and off, etc.

Downloaded from