1-32

1.14 DATACORDER MODULE (OPTIONAL)

1. DataCorder Module

2. Battery Pack (Optional)

3. Software Port

4. Connector

5. Status LED’s

6. Fuse

7. Manual Battery Switch

1

2

3

4

5

6

7

4

4

Figure 1-11. DataCorder Module

1.14.1 Brief Description

WARNING

Do not attempt to service the DataCorder

module, breaking the warranty seal will void the

warranty.

CAUTION

Remove DataCorder module and unplug all wire

harness connectors before performing any arc

welding on any part of the container.

Do not remove wire harnesses from module

unless you are grounded to the unit frame with a

static safe wrist strap.

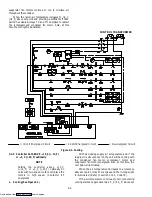

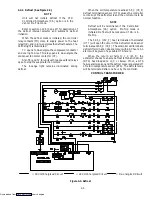

Carrier Transicold has developed a recorder, which

we have termed the “DataCorder”, in a self-contained

module which consists of:

--- Microprocessor

--- Program memory

--- Data memory

--- Real time clock (RTC)

--- Six thermistor inputs

--- Two voltage inputs

--- Four status LED’s

--- Two communication ports

--- Power supply (optional battery pack).

This recorder eliminates the mechanical recorder

and paper chart, and replaces it with a custom-designed

module (see Figure 1-11) that interfaces with the

controller module and the Interrogator to:

a. Operate as a stand alone device or in conjunc-

tion with other modules such as the Temperature Con-

troller, CTD Controlled Atmosphere (CA) Controller,

etc.

b. Log data at 15, 30, 60 or 120 minute intervals.

c. Record DataCorder alarms and display through

the Temperature Controller digital display identification.

(Refer to Table 1-10.)

d. Store at least one years worth of data based on

continuous unit operation at factory default settings.

Factory default settings are:

One (1) hour logging interval.

Configured for two (2) probes.

e. Record DataCorder/Network generated data

and events as follows:

--- Container ID Change

--- Controller S/W Upgrade

--- Controller Replacement

--- DataCorder Alarm Activity

--- DataCorder Battery Low (Battery Pack)

--- DataCorder S/W Upgrade

--- Data Retrieval

--- Defrost Start

--- Defrost End

--- Dehumidification Start

--- Dehumidification End

--- Controller Alarm Activity

--- Controller Communication Not Responding

--- Controller Communication Responding

--- Power Loss (w/wo battery backup)

--- Power Up (w/wo battery backup)

--- “Auto 1” Pre-Trip Start

--- “Auto 1” Pre-Trip End

--- Remote Probe Temperatures in the Container

(USDA Cold treatment and Cargo

probe recording)

--- Return Air Temperature

--- Set Point Change

--- Supply Air Temperature

--- Real Time Clock (RTC) Battery

(Internal Battery) Replaced

--- Real Time Clock (RTC) Modification

--- Trip Start

--- Economy Mode Start

--- Economy Mode End

--- “Auto 2” Pre-Trip Start

--- “Auto 2” Pre-Trip End

Downloaded from