1-40

1.16 HUMIDITY CONTROL (OPTIONAL)

NOTE

The supply air must be in-range for the humidity

circuit to energize.

The humidity control is designed to operate when

transporting a chill load, controller set above ---10

_

C

(+14

_

F) or ---5

_

C (+23

_

F) optionally, and is locked out

when the controller is set below ---10

_

C or ---5

_

C

(optionally).

Code Cd33 is factory set at 70% R.H. for units

equipped with a humidity sensor and configured for

humidity sensing. When humidity configuration is

“OFF”, this means either the unit is not equipped with a

humidity sensor or has not been configured for humidity

control. (See Cd33, page 1---24)

a. The humidity control will be in operation if:

1. Unit is equipped with a humidity sensor and

configured for dehumidification.

2. Supply air is in-range (in-range light

illuminated).

3. Dehumidification control code Cd33 is properly

set for desired R.H.

4. Controller is set above ---10

_

C (+14

_

F) or ---5

_

C

(+23

_

F) optionally.

5. Container relative humidity is above 2% of code

Cd33 setting.

If all 5 factors are met, the humidity control circuit

energizes the heaters and heat light.

b. For testing purposes:

WARNING

Beware of rotating evaporator fan when

conducting following test.

1. Set the controller set pointer within 2

_

C (3.6

_

F)

of container supply air temperature.

2. Change the set point of code Cd33 to test the

heaters. They should be energized (heat light ON) and

then reset code Cd33 to the desired level.

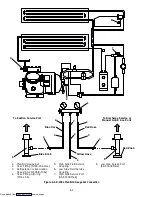

1.17 NITROGEN FEED (OPTIONAL)

The purpose of the nitrogen feed option is to provide

a way to inject nitrogen into the air stream of the unit.

This is done by connecting a nitrogen line to the

quick-connect on the front of the unit, with a 1/4” nipple

conforming to the MIL-C-4109. The nitrogen can then be

feed into the unit. The unit is equipped with a pressure

relief device to prevent the pressure in the container from

exceeding two inches water gauge.

WARNING

Do not use a nitrogen feed inlet pressure higher

than 35 PSI.

Downloaded from