2-3

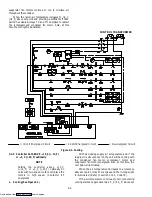

point. The modulating valve will have a variable current

up to 1.30 amps at full modulation.

During this cooling mode, a running sum of the

temperature differential (supply air temperature --- set

point) is kept. When the supply air falls below set point,

the differential is negative. The longer supply air remains

below set point, the more negative the running sum

becomes.

When the supply air temperature decreases to 0.2

_

C

below set point and the running sum is less than ---250

degrees C seconds, relays TN and TC de-energize

shutting off the condenser fan and compressor motors.

Also, the cool light is de-energized.

The evaporator fan motors continue to run to

circulate air throughout the container. The in-range light

remains illuminated as long as the supply air is within a

tolerance of set point, and the 15 minute override is met.

If the unit is in the holding mode (neither heating or

cooling) and the supply air temperature increases to

0.2

_

C (0.4

_

F) above set point, and providing a 3 minute

off time has elapsed, relay TC energizes to restart the

compressor. Also, at this time, the condenser fan motor

starts and the cool light is illuminated.

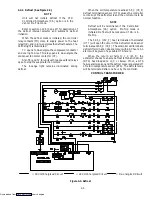

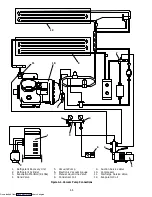

b. Heating (See Figure 2-2.)

The unit

will only heat

when the controller set point is

above ---10

_

C (+14

_

F) or ---5

_

C (+23

_

F) optionally as

relay TH is electronically locked out to prevent heating

when the controller set point is

below

---10

_

C (+14

_

F) or

---5

_

C (+23

_

F) optionally.

If the air temperature decreases 0.5

_

C (0.9

_

F) below

controller set point, TH closes and the system enters the

heating mode which is designed to raise the container air

temperature. When TH closes, power flows through TH

contacts and the heat termination thermostat to energize

the heat relay (HR). This in turn energizes the heaters

and heat light. The evaporator fans continue to run to

circulate air throughout the container.

As the supply air decreases to the in-range tolerance

below set point, relay TI and the in-range light

de-energize (after 15 minutes time delay) and will remain

de-energized until the supply air increases to a tolerance

below set point. (Refer to section 1.12.5, Code 30)

When the temperature rises to 0.2

_

C (0.4

_

F) below

set point, TH opens (heating off) and the system again

enters the holding zone. The compressor and condenser

fan motor are not running as contactors C and CF remain

de-energized. The evaporator fans continue to run to

circulate air throughout the container.

A safety heater termination thermostat (HTT)

attached to an evaporator coil support, set to open at

54.5

_

C (130

_

F), will open the heating circuit if

overheating occurs.

Downloaded from