4-3

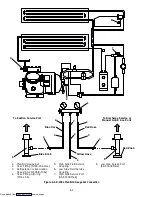

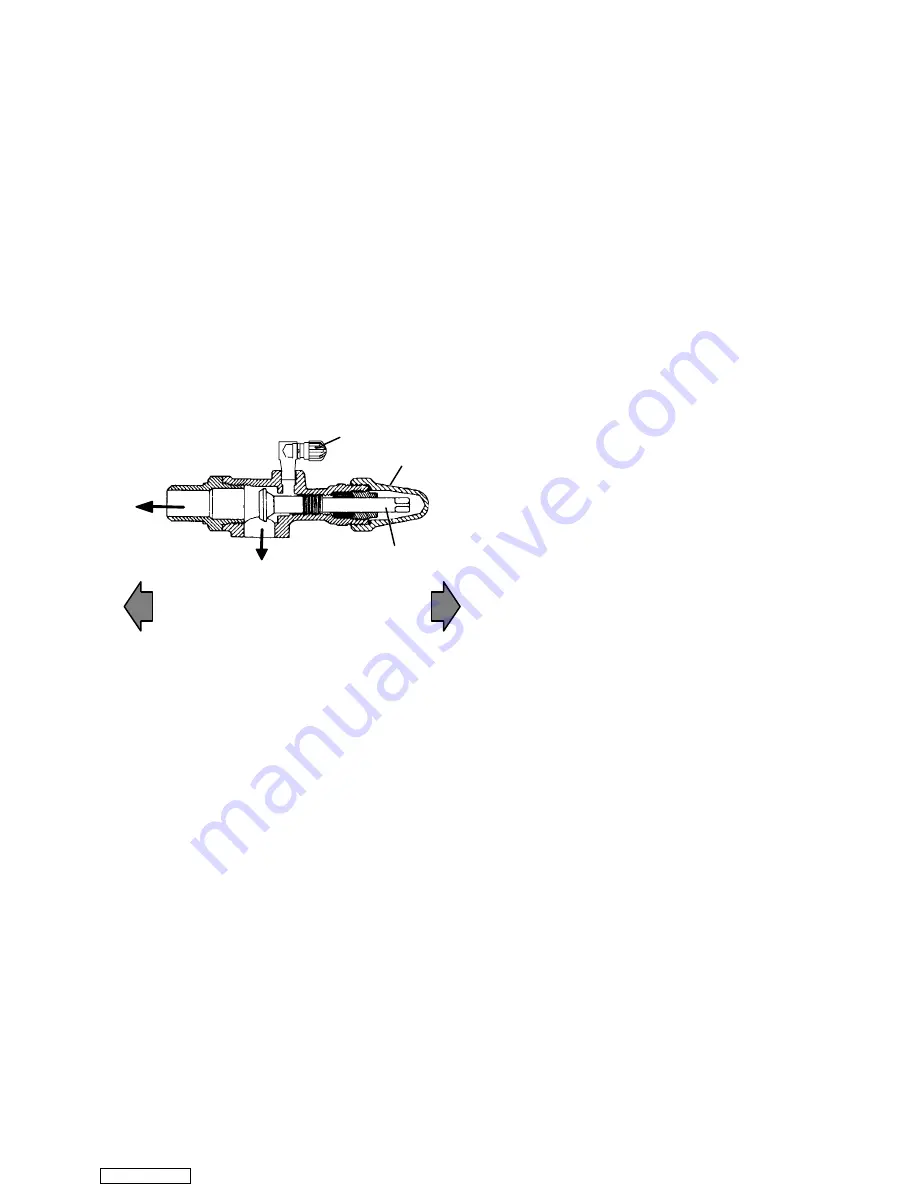

4.2 SUCTION AND DISCHARGE SERVICE VALVES

The suction and discharge service valves used on the

compressor are equipped with mating flanges for

connection to flanges on the compressor. These valves are

provided with a double seat and a gauge connection, which

enable servicing of the compressor and refrigerant lines.

Turning the valve stem clockwise (all the way forward)

will frontseat the valve to close off the suction or discharge

line and opens the gauge connection to the compressor. See

Figure 4-3. Turning the valve stem counterclockwise (all the

way out) will backseat the valve to open the suction or

discharge line to the compressor and close off the gauge

connection.

With the valve stem midway between frontseated and

backseated positions, suction or discharge line is open to

both the compressor and the gauge connection.

For example, when connecting a manifold gauge to

measure suction or discharge pressure, the valve stem is

fully backseated. Then, to measure suction or discharge

pressure, crack open the valves 1/4 to 1/2 turn.

Gauge Connection

Valve Cap

Valve Stem

To Suction or

Discharge Line

Compressor

Valve

Frontseated

(clockwise)

Valve

Backseated

(counterclockwise)

Figure 4-3. Suction or Discharge Service Valve

4.3 PUMPING THE UNIT DOWN OR

REMOVING THE REFRIGERANT

NOTE

To avoid damage to the earth’s ozone layer, use

a refrigerant recovery system whenever removing

refrigerant. When working with refrigerants you

must comply with all local government

environmental laws, U.S.A. EPA section 608.

a. Pumping the Unit Down

To service the filter-drier, moisture-liquid indicator,

expansion valve, suction modulation valve, suction solenoid

valve or evaporator coil, pump most of the refrigerant into

the condenser coil and receiver as follows:

1. Install gauges and mid seat the suction and

discharge valves (turn clockwise) as specified in section

4.1.a.

2. Allow the compressor to run 10 to 15 minutes.

Then close (front seat) liquid line valve by turning

clockwise. Start the unit and run in a cooling mode. Place

start-stop switch in the OFF position when the unit reaches

and maintains a positive pressure of 0.1 kg/cm

@

(1.0 psig).

NOTE

The unit may need to be cycled several times to

achive this reading.

3. Frontseat (close) the suction service valve and the

refrigerant will be trapped between the compressor suction

service valve and the liquid line valve.

4. Before opening up any part of the system, a slight

positive pressure should be indicated on the pressure gauge.

If a vacuum is indicated, emit refrigerant by cracking the

liquid line valve momentarily to build up a slight positive

pressure 0.1 kg/cm

@

(1.0 psig)..

5. When opening up the refrigerant system, certain

parts may frost. Allow the part to warm to ambient

temperature before dismantling. This avoids internal

condensation which puts moisture in the system.

6. After repairs have been made, be sure to perform

a refrigerant leak check (section 4.4), and evacuate and

dehydrate the system (section 4.5).

7. Check refrigerant charge (Refer to section 4.6).

4.4 REFRIGERANT LEAK CHECKING

WARNING

Never mix refrigerants with air for leak testing. It

has been determined that pressurized, air-rich

mixtures of refrigerants and air can undergo

combustion when exposed to an ignition source.

a. The recommended procedure for finding leaks in a

system is with a R-134a electronic leak detector. Testing

joints with soapsuds is satisfactory only for locating large

leaks.

b. If the system is without refrigerant, charge the system

with refrigerant to build up pressure between 2.1 to 3.5

kg/cm

@

(30 to 50 psig). Remove refrigerant cylinder and

leak check all connections.

NOTE

It must be emphasized that only the correct

refrigerant cylinder be connected to pressurize the

system. Any other gas or vapor will contaminate

the system which will require additional purging

and evacuation of the system.

c. Remove refrigerant using a refrigerant recovery system

and repair any leaks.

d. Evacuate and dehydrate the unit. (Refer to section 4.5)

e. Charge unit per section 4.6.

4.5 EVACUATION AND DEHYDRATION

4.5.1 General

Moisture is the deadly enemy of refrigeration systems.

The presence of moisture in a refrigeration system can have

many undesirable effects. The most common are copper

plating, acid sludge formation, “freezing-up” of metering

devices by free water, and formation of acids, resulting in

metal corrosion.

4.5.2 Preparation

a. Evacuate and dehydrate only after pressure leak test.

(Refer to section 4.4)

Downloaded from