4-7

4.7 COMPRESSOR MODEL 06DR REPLACEMENT

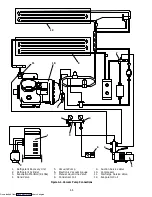

(See Figure 4-5.)

WARNING

Make sure power to the unit is OFF and power

plug disconnected before replacing the

compressor.

1

2

3

4

5

6

7

8

10

11

12

13

14

15

1. Discharge Valve Flange

2. High Side Pressure Connection

3. Low Side Pressure Connection

4. Suction Valve Flange

5. Motor End Cover

6. Serial/Model No. Plate

7. Crankcase Heater (Optional)

8. Bottom Plate

9. Sight Glass

10. Oil Drain Plug

11. Bearing Head

12. Oil Pump (See Figure 4-6)

13. Oil Fill Plug (Refer to section 4.10)

14. Cylinder Head

15. Valve Plate

9

Figure 4-5. Compressor --- Model 06DR

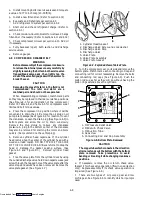

Gear Pump

Low Profile Gear Pump

Figure 4-6. Oil Pump

There are two types of oil pumps; gear and low

profile gear. Force-feed lubrication of the compressor is

accomplished by a oil pump driven directly from the

compressor crankshaft. Refrigeration oil is drawn from

the compressor crankcase through the oil filter screen

and pick up tube to the oil pump located in the bearing

head assembly. The crankshaft is drilled to enable the

pump to supply oil to the main bearings, connecting rod

bearings, and the shaft seal.

NOTES

1. Check the compressor Serial/Model Number

plate for CFM displacement, refer to Table 1-2.

2. The compressor should not operate in a vacuum

greater than 500 mm Hg vacuum (20 inches Hg

vacuum).

3. The service replacement compressor is sold

without shutoff valves (but with valve pads), and

without terminal box and cover. Customer

should retain the original terminal box, cover,

and high pressure switch for use on replacement

compressor.

4. Check oil level in service replacement

compressor. (Refer to sections 1.3 and 4.10.)

5. A compressor terminal wiring kit must be

ordered as a separate item when ordering

replacement

compressor.

Appropriate

installation instructions are included with kit.

6. Refer to Table 4-4 and Table 4-5, for applicable

compressor wear limits and torque values.

7. Refer to Figure 4-32 for charts on compressor

pressure-temperature and motor current curves.

a. Remove the protective guard from lower section of

the unit.

b. Remove refrigerant. (Refer to section 4.3)

c. Disconnect wiring in the compressor junction box

after identifying same. Disconnect wiring from

compressor terminals and remove compressor junction

box.

d. Remove bolts from service valve flanges.

e. To remove the optional crankcase heater (CCH),

refer to Figure 4-5. Remove cushion clamp from the

mounting bracket. Unbolt and remove crankcase heater

mounting bracket. Pull heater straight out of crankcase.

f. Remove compressor plate mounting bolts.

g. Remove compressor and mounting plate. The

compressor weighs approximately 118 kg (260 pounds).

h. Remove high pressure switch (HPS) from

compressor and check operation of switch (refer to

section 4.13.2).

i.

Remove compressor mounting bolts from mounting

plate and install mounting plate on replacement

compressor.

j.

Install replacement compressor terminal wiring kit

(following instructions included with kit).

k. Install high pressure switch on compressor.

l.

Install compressor and mounting plate in unit.

m. Install junction box to compressor and connect all

wiring per wiring diagram and then install junction box

cover.

n. Install new gaskets on service valves.

Downloaded from