4-13

c. After unit is in operation, inspect for moisture in

system. (Refer to section 4.11.)

4.13 HIGH PRESSURE SWITCH

4.13.1 Replacing High Pressure Switch

a. Turn OFF unit start-stop switch. Frontseat both suction

and discharge service valves to isolate compressor. Remove

the refrigerant from the compressor.

b. Disconnect wiring from defective switch. The high

pressure switch is located on the center head and is

removed by turning counterclockwise. (See Figure 1-1.)

c. Install a new high pressure switch after verifying

switch settings. (Refer to section 4.13.2.)

d. Evacuate and dehydrate the compressor per

section 4.5.1.

4.13.2 Checking High Pressure Switch

WARNING

Do not use a nitrogen cylinder without a

pressure regulator. Do not use oxygen in or near

a refrigeration system as an explosion may

occur.

NOTE

The high pressure switch (HPS) is non-adjustable.

a. Remove switch as outlined in section 4.13.1.

b. Connect ohmmeter or continuity light across switch

terminals. Ohm meter will indicate no resistance or

continuity light will be illuminated if switch closed after

relieving compressor pressure.

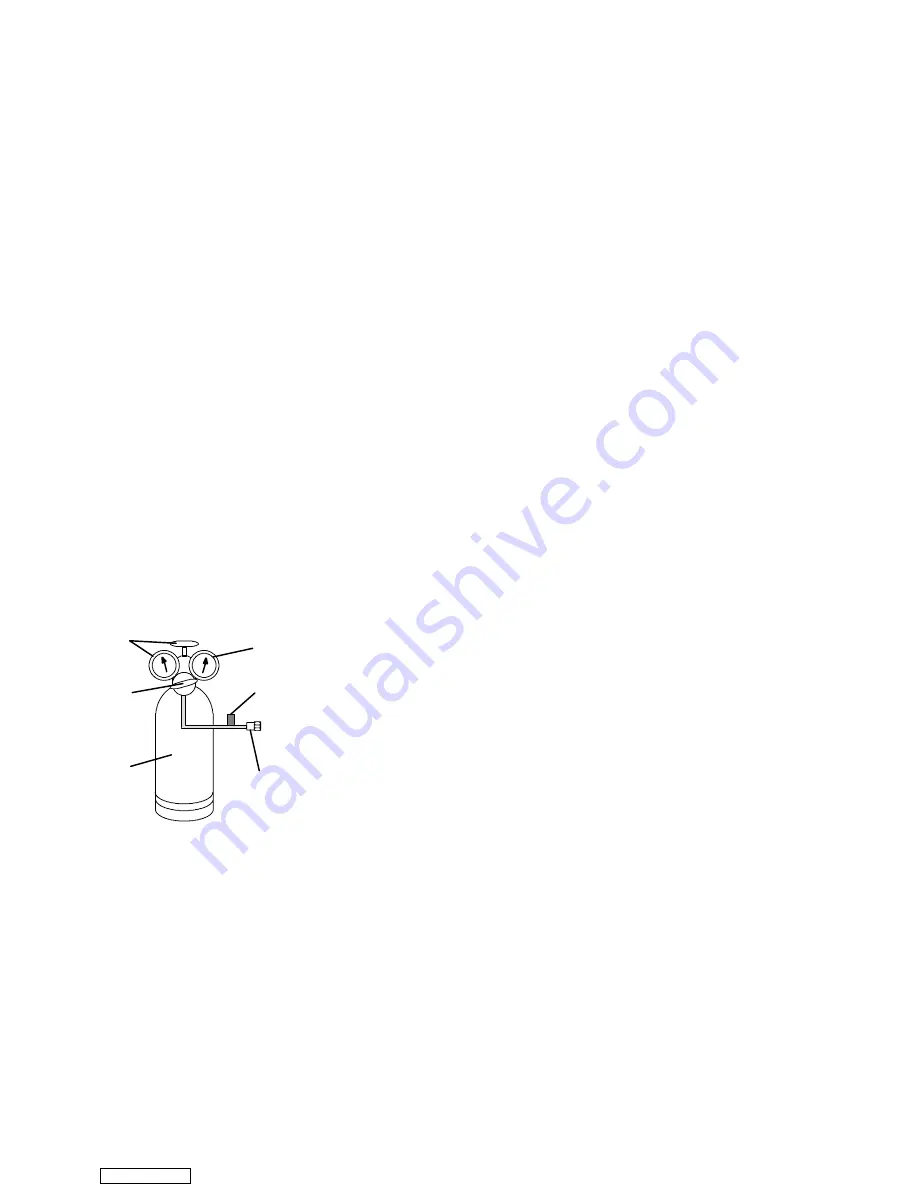

c. Connect hose to a cylinder of dry nitrogen. (See

Figure 4-17.)

1. Cylinder Valve

and Gauge

2. Pressure Regulator

3. Nitrogen Cylinder

4. Pressure Gauge

(0 to 36 kg/cm

@

=

0 to 400 psig)

5. Bleed-Off Valve

6. 1/4 inch Connection

1

2

3

4

5

6

Figure 4-17. Typical Setup for

Testing High Pressure Switch

d. Set nitrogen pressure regulator at 26.4 kg/cm

@

(375

psig) with bleed-off valve closed.

e. Close valve on cylinder and open bleed-off valve.

f. Open cylinder valve. Slowly close bleed-off valve to

increase pressure on switch. The switch should open at a

static pressure up to 25 kg/cm

@

(350 psig). If light is used,

light will go out and if ohmmeter is used, the meter will

indicate open circuits.

g. Slowly open bleed-off valve to decrease the pressure.

The switch will close at 18 kg/cm

@

(250 psig).

4.14 EVAPORATOR COIL AND HEATER ASSEMBLY

The evaporator section, including the coil, should be

cleaned with fresh water or steam, preferably. Another

recommendation is to use Oakite 202 or similar cleaner

following

manufacturer’s instructions.

The two drain pan hoses connected to the drain pan,

are routed behind the condenser fan motor and

compressor. The drain pan line(s) must be open to ensure

adequate drainage.

To Replace Evaporator Coil:

a. Pump unit down. (See Figure 1-3, refer to section 4.3.)

b. With power OFF and power plug removed, remove

the screws securing the panel covering the evaporator

section (upper panel).

c. Disconnect the defrost heater wiring.

d. Disconnect the sensor from the coil. The defrost

termination sensor (DTS) is located on the middle coil

support as shown in Figure 1-2.

e. Remove middle coil support.

f. Remove the mounting hardware from the coil.

g. Unsolder the two coil connections, one at the

distributor and the other at the coil header.

h. After defective coil is removed from unit, remove

defrost heaters and install on replacement coil.

i.

Install coil assembly by reversing above steps.

j.

Leak check connections per section 4.4. Evacuate

the unit per section 4.5 and add refrigerant charge per

section 4.6.2.

4.15 EVAPORATOR FAN AND MOTOR ASSEMBLY

The evaporator fans circulate air throughout the

container by pulling air in the top of the unit. The air is

forced through the evaporator coil where it is either

heated or cooled and then discharged out the bottom of

the refrigeration unit into the container. (Refer to

section 1.4.)

The fan motor bearings are factory

lubricated and do not require additional grease.

WARNING

Always turn OFF the unit circuit breakers (CB-1

& CB-2) and disconnect main power supply

before working on moving parts.

a. Remove upper access panel (See Figure 1-1) by

removing mounting bolts and T.I.R. locking device.

Reach inside of unit and remove Ty-Rap securing wire

harness loop.

b. Remove the two lower mounting bolts that secure the

motor-fan assembly to the unit. Loosen the two upper

bolts as the motor mount upper holes are slotted.

c. Remove motor, fan, and wiring from unit. Place fan

motor and fan on a support. Remove the wiring and fan.

d. Lubricate fan motor shaft with a graphite-oil

solution (Never-Seez). Apply thread sealer (Loctite H,

brown in color) to the two fan set screws. Install fan on

motor. The evaporator fan locating dimension is shown

in Figure 4-18.

Downloaded from