1-1

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

WARNING

It has been determined that pressurized,

air-rich mixtures of refrigerants and air can

undergo combustion when exposed to an

ignition source.

This manual contains Operating Data, Electrical

Data and Service Instructions for the refrigeration units

listed in Table 1-1. Also Table 1-1 charts some significant

differences between these models.

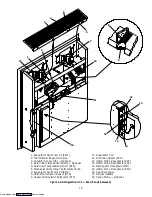

The unit, of lightweight aluminum frame

construction, is an all electric, one piece self-contained,

cooling and heating, refrigeration unit. The unit is

designed to fit in the front of a container and to serve as

the container front wall. Fork lift pockets are provided

for installation and removal of the unit.

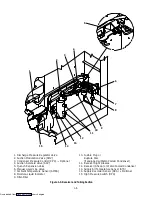

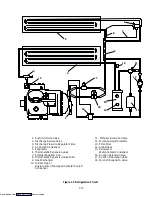

The unit is complete with a charge of R-134a,

compressor lubricating oil (approved POE SW20

compressor oil for R-134a only), mode indicating lights,

temperature controller and is ready for operation upon

installation.

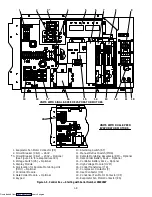

Some units are dual voltage, designed to operate on

190/230 or 380/460 volts AC, 3 phase, 50-60 hertz power.

(Refer to section 1.5) Other units are designed to operate

on 380/460 volts AC, 3 phase 50/60 hertz power only.

Operating control power is provided by a control

transformer which steps down the AC supply power

source to 18 to 24 volts and 30 to 36 voltsAC, 1 phase

control power.

The temperature controller (Micro-Link 2) is a

microprocessor based controller. Refer to section 1.12.

Once the temperature controller is set at a desired

container

temperature,

the

unit

will operate

automatically to maintain the desired temperature

within very close limits. The control system automatically

selects cooling, holding or heating as necessary to

maintain the desired temperature within the container.

WARNING

Beware of unannounced starting of the

evaporator and condenser fans. Do not open the

condenser fan grille before turning power OFF

and disconnecting power plug.

Some units are equipped with a Carrier Transicold

DataCorder (microprocessor based recorder). Detailed

information on the DataCorder will be found in section

1.14. Some units are equipped with a Partlow mechanical

temperature recorder or a Saginomiya battery driven

temperature recorder.

Some units may have the integrated CTD EverFresh

Controlled Atmosphere option installed. Refer to the

Model Chart in Table 1-1. Separately bound manuals

covering the CTD EverFresh Controlled Atmosphere

option are also supplied, see chart below:

Manual

Number

Equipment

Covered

Type of

Manual

T-265

Controlled

Atmosphere option

Operation and

Service

T-265PL

Controlled

Atmosphere option

Service Parts

List

Some units may have a TransFRESH controlled

atmosphere system added. Contact TransFRESH

Corporation, P.O. Box 1788, Salinas, CA 93902 for

information on their system.

Downloaded from