2-13

T-294-01

2.7 UPPER FRESH AIR MAKEUP VENT

The purpose of the upper fresh air makeup vent is to

provide ventilation for commodities that require fresh

air circulation. The vent

must be closed

when

transporting frozen foods.

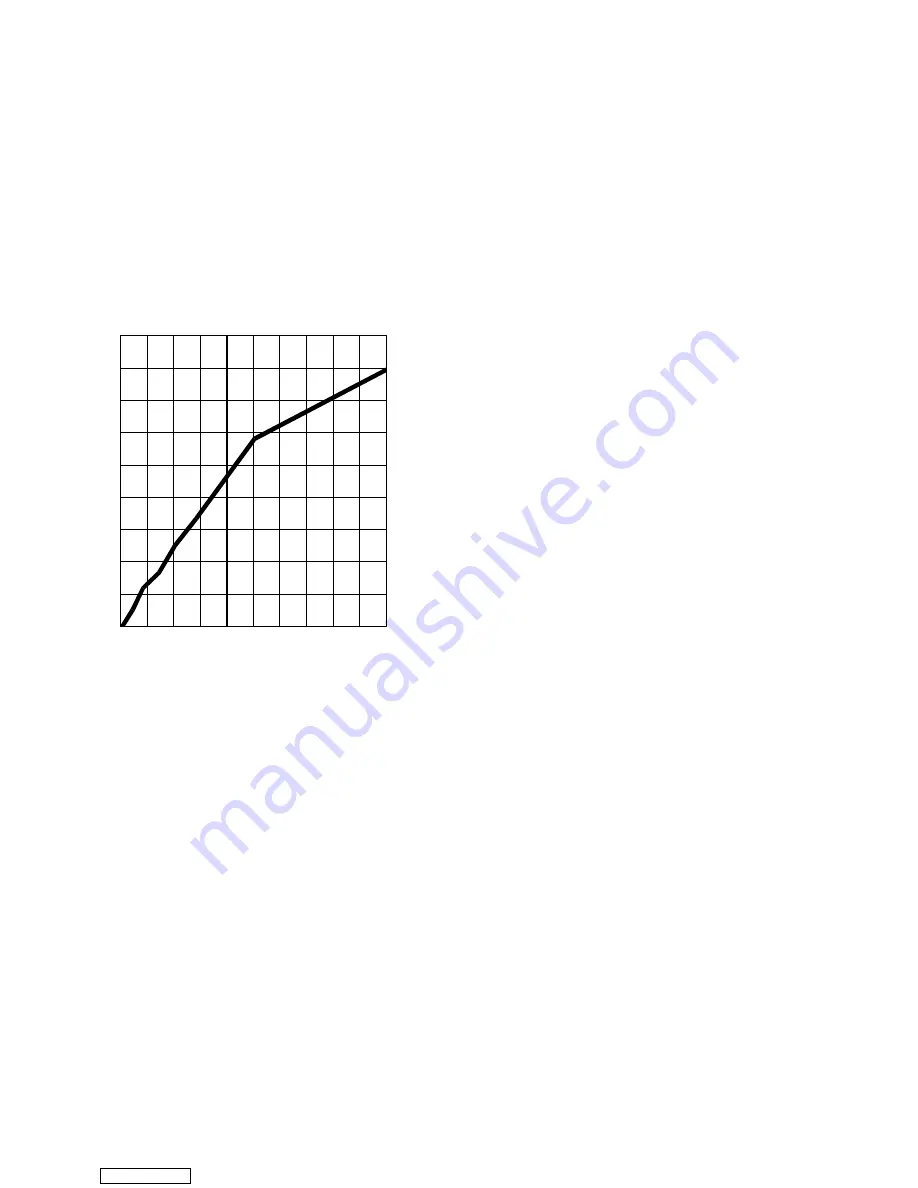

Air exchange depends on static pressure differential,

which will vary depending on the container and how the

container is loaded. The chart below gives air exchange

values for an empty container. Higher values can be

expected for a fully loaded container.

0

25

50

75

100

125

150

175

200

225

0

10 20 30 40 50 60 70 80 90 100

AIR

FLOW

(CMH)

2-3/8

”

PERCENT OPEN

T-BAR

ZERO EXTERNAL STATIC PRESSURE,

50HZ POWER

For 60HZ operation multiply air flow values from curve by 1.2

a. Full Open or Closed Positions

Maximum air flow is achieved by loosening the wing

nut and rotating the disc to the maximum open position

(100% open). The closed position is 0% air flow.

Two slots and a stop are designed into the disc for air

flow adjustments. The first slot allows for a 0 to 30% air

flow, and the second slot allows for a 30 to 100% air

flow. To increase the percentage of air flow, the wing

nut must be loosened, and the disc rotated until the

desired percentage of air flow matches with the arrow on

the disc. Tighten the wing nut. To clear the gap between

the slots, loosen the wing nut until the disc clears the

stop, and rotate the disc for the second slot.

The operator may also increase or decrease the air flow

volume to meet the required air flow by aligning the

arrow on the disc with the percentage of desired air flow

marked on the supplied label (see Figure 2-1).

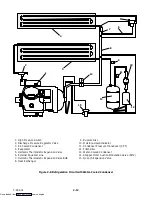

2.8 LOWER FRESH AIR MAKEUP VENT

(Optional)

The purpose of the lower fresh air makeup vent is to

provide ventilation for commodities that require fresh

air circulation. The vent

must be closed

when

transporting frozen foods.

Air exchange depends on static pressure differential,

which will vary depending on the container and how the

container is loaded. The chart across gives air exchange

values for an empty container. Higher values can be

expected for a fully loaded container.

a. Full Open or Closed Positions

The air slide is supplied with two adjustable air control

discs. The fresh air makeup can be adjusted for 15, 35,

50 and 75 cubic meters per hour (CFM). The air flow has

been established at 60 Hz power, and a 2 1/2 inch T bar,

with 15 mm (0.6 inch) H

2

O external static above free

blow.

Maximum air flow is achieved by loosening the hex

nuts and rotating each disc to the maximum open

position (100% open). The closed position is 0% air

flow.

The operator may also adjust the openings to increase or

decrease the air flow volume to meet the required air

flow.

NOTE

The main air slide is in the fully closed position

during reduced air flow operation.

a. Air Sampling for Carbon Dioxide (CO

2

) Level

Loosen hex nuts and move the cover until the arrow on

the cover is aligned with the “atmosphere sampling

port” label. Tighten the hex nuts and attach a 3/8 hose to

the sampling port.

If the internal atmosphere content has reached an

unacceptable level, the operator may adjust the disc

opening to meet the required air flow volume to

ventilate the container.

Downloaded from