6-14

T-294-01

7. Install the oil suction screen, the oil suction screen

hold down plate and the bottom plate.

Figure 6-17. Compressor Oil Pump End View

6.11 COMPRESSOR OIL LEVEL

CAUTION

Use only Carrier Transicold approved

Polyol Ester Oil (POE) -- Castrol-Icematic

SW20 compressor oil with R-134a. Buy in

quantities of one quart or smaller. When

using this hygroscopic oil, immediately

reseal. Do not leave container of oil open or

contamination will occur.

a. Checking the Oil Level in the Compressor

1. Operate the unit in cooling mode for at least 20

minutes.

2. Check the front oil sight glass on the compressor to

ensure that no foaming of the oil is present after 20

minutes of operation. If the oil is foaming

excessively after 20 minutes of operation, check the

refrigerant system for flood-back of liquid

refrigerant. Correct this situation before performing

step 6.11.a.3.

3. Turn unit off to check the oil level. The correct oil

level range should be between the bottom to

one-eighth level of the sight glass. If the level is

above one-eighth, oil must be removed from the

compressor. To remove oil from the compressor,

follow step d in this section. If the level is below the

bottom of the sight glass, add oil to the compressor

following step b below.

b. Adding Oil with Compressor in System

In an emergency where an oil pump is not available, oil

may be drawn into the compressor through the liquid

line process tube.

CAUTION

Extreme care must be taken to ensure the

manifold common connection remains

immersed in oil at all times. Otherwise air

and moisture will be drawn into the

compressor.

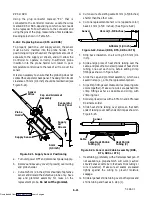

Connect the suction connection of the gauge manifold

to the compressor liquid line process tube (refer to

sections 6.3 and 6.4), and immerse the common

connection of the gauge manifold in an open container

of refrigeration oil. Crack the manifold gauge valve to

vent a small amount of refrigerant through the common

connection and the oil to purge the lines of air. Close the

gauge manifold valve.

With the unit running, SLOWLY frontseat the manifold

liquid hand valve and induce a vacuum in the

compressor crankcase. Oil will flow through the liquid

line process tube into the compressor. Add oil as

necessary.

Run unit for 20 minutes in cooling mode. Check oil

level at the compressor sight glass.

c. Adding Oil to Service Replacement Compressor

NOTES

S

The correct oil charge is 3.6 liters (7.6 U.S.

pints).

S

Service replacement compressors are

shipped without oil.

S

When first adding oil to the compressor,

add only three liters (6.3 pints) to the

compressor. Run the unit for 20 minutes in

cooling mode. Check the oil level in the

compressor sight glass. Add oil as necessary.

This procedure is designed to compensate for

excess oil that may have migrated with

refrigerant to other parts of the system during

unit operation.

If compressor is without oil:

If oil is present in the compressor, ensure that it is the

correct oil. Add oil (refer to sections 2.2 and 6.11)

through the oil fill plug. (See Figure 6-6.) Some

compressors have the oil plug located on the crankcase,

at the right or left side of the oil pump.

Downloaded from