6-15

T-294-01

d. Removing Oil from the Compressor

1. If the oil level recorded in step a.3 is above

one-eighth level of the capacity of the sight glass,

oil must be removed from the compressor.

2. Close (frontseat) the manifold liquid hand valve

and pump unit down to 1.2 to 1.3 kg/cm

@

(2 to 4

psig). Frontseat the manifold vapor hand valve and

slowly bleed remaining refrigerant.

3. Remove the oil drain plug on the bottom plate of the

compressor and drain the proper amount of oil from

the compressor to obtain the correct level

(maximum is one-eight level of the sight glass).

Replace the plug securely back into the compressor.

4. Repeat step (a) to ensure proper oil level.

5. Return the system to its hermetic state by referring

to section 6.4.

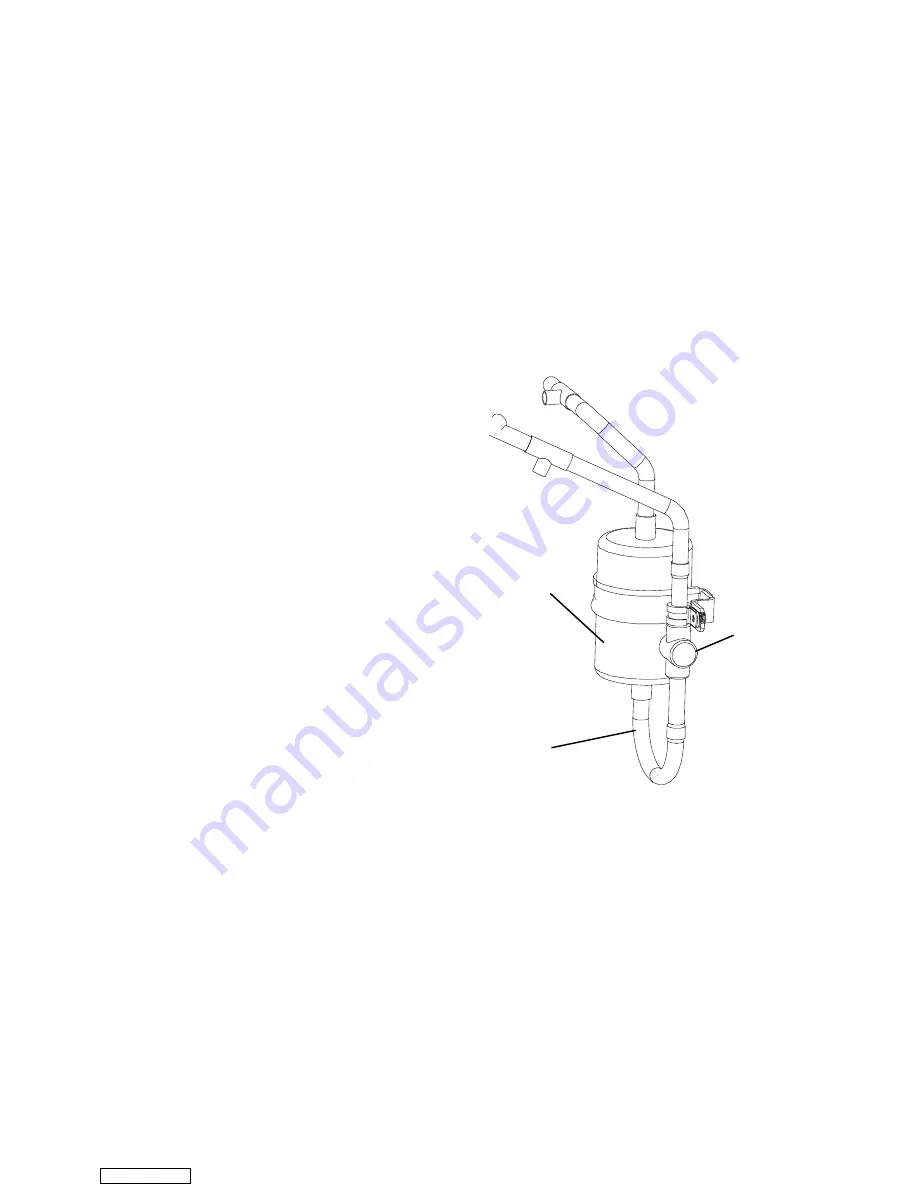

6.12 FILTER-DRIER

On units equipped with a water-cooled condenser, if the

sight glass appears to be flashing or bubbles are

constantly

moving through the moisture liquid

indicator/sight glass when the suction modulation valve

is fully open, the unit may have a low refrigerant charge

or the filter-drier could be partially plugged.

a.

To Check Filter-Drier

1. Test for a restricted or plugged filter-drier by feeling

the liquid line inlet and outlet connections of the

drier cartridge. If the outlet side feels cooler than the

inlet side, then the filter-drier should be changed.

2. A second test for moisture in the filter-drier is that

the moisture-liquid indicator shows moisture in the

system.

b.

To Replace Filter-Drier

WARNING

Residual system oil can cause a fire and

potential injury. To avoid the possibility of

an oil fire when replacing the filter drier use

the following procedure.

Oil Fire extinguishing source is REQUIRED

to be at your disposal during the repair.

NOTE

Run unit in a FULL COOL operation for 20

minutes before beginning Procedure. This will

circulate the majority of the oil back to the

compressor.

1. Recover refrigerant (refer to section 6.4) and

replace filter-drier. Do not allow contaminants and

moisture into the system.

2. Evacuate the unit per section 6.6.

3. After unit is in operation, inspect for moisture in

system.

4. Remove strap from around the filter drier.

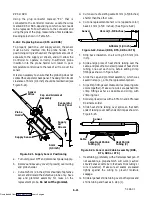

5. Using a small tube cutter, cut the liquid line just

below the moisture--line indicator. Make the cut

just below the brazed joint of the moisture--line

indicator and U--tube. Approximately, 1 inch below

the brazed joint. Refer to Figure 6-18.

Filter Drier

Moisture-Line

Indicator

U-tube

(needs to be pierced

to remove residual oil)

Figure 6-18. Filter-Drier and U-tube

6. Using the small tube cutter, cut the U--tube just

below the filter drier, and remove the old U--tube

completely.

7. Allow oil to drain.

WARNING

Due to the nature of refrigeration systems,

there may be some residual oil. There is still

a potential for fire.

Be prepared to

extinguish the fire.

8. Braze out the filter drier and remains of the U--tube,

use kit P/N 76--50085--00 and braze in the new Filter

Drier and U--tube.

Downloaded from