6-20

T-294-01

6.20 MAINTENANCE OF PAINTED SURFACES

The refrigeration unit is protected by a special paint

system against the corrosive atmosphere in which it

normally operates. However, should the paint system be

damaged, the base metal can corrode. In order to protect

the refrigeration unit from the highly corrosive sea

atmosphere, or if the protective paint system is

scratched or damaged, clean area to bare metal using a

wire brush, emery paper or equivalent cleaning method.

Immediately following cleaning, spray or brush on

zinc-rich primer. After the primer has dried, spray or

brush on finish coat of paint to match original unit color.

6.21 POWER AUTOTRANSFORMER (TRANS) --

Optional

If the unit does not start, check the following:

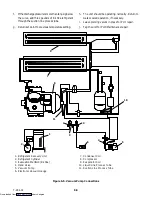

a. Make sure the 460 vac (yellow) power cable is

plugged into the receptacle (item 3, Figure 2-7) and

locked in place.

b. Make sure that circuit breakers CB-1 and CB-2 are

in the “ON” position. If the circuit breakers do not

hold in, check voltage supply.

c. There is no internal protector for this particular

transformer design, therefore, no checking of the

internal protector is required.

d. Using a voltmeter, and with the primary supply

circuit ON, check the primary (input) voltage (460

vac). Next, check the secondary (output) voltage

(230 vac). The transformer is defective if voltage is

not available.

6.22 TRANSFORMER BRIDGING UNIT (TBU)

The transformer bridging unit (TBU) will reduce

attenuation (i.e., loss of signal power in a transmission)

that occurs when a high frequency remote monitoring

unit

(RMU)

signal

is

passed

through

an

autotransformer. The TBU allows high frequency

remote monitoring signals to effectively bypass the

460/230 vac autotransformer (TRANS).

WARNING

Before servicing unit, make sure the unit

circuit breakers (CB-1 & CB-2) and the

start-stop switch (ST) are in the OFF

position, and that the power plug and cable

are disconnected.

If the device does not appear to be functioning, check

the following:

a. Make sure power to the unit is OFF.

b. Refer to Figure 2-7 for the location of TBU.

c. Disconnect

the

TBU

from

across

the

autotransformer. This will isolate the device and

allow for accurate measurements.

d. Using a capacitor meter (i.e., Fluke 87), measure

between L1 and L1, L2 and L2, L3 and L3.

e. The readings should be 0.44

µ

F, plus or minus 14%.

f. If the readings do NOT fall in the above described

range, the device must be replaced.

NOTE

An ohmmeter may be used as a cross check for

shorted capacitors in the TBU. However, it will

NOT accurately check for an open capacitor; as

the ohmmeter will read open for both good or

open capacitors.

6.23 SENSOR CHECKOUT PROCEDURE (AMBS,

DTS, RRS, RTS, SRS & STS)

An accurate ohmmeter must be used to check the

resistance values shown in Table 6-5.

Due to the variations and inaccuracies in ohmmeters,

thermometers or other test equipment, a reading within

2% of the chart value would indicate a good sensor. If a

sensor is defective, the resistance reading will usually

be much higher or lower than the resistance values given

in Table 6-5.

6.23.1 Checking Sensor (RRS, RTS, SRS or STS)

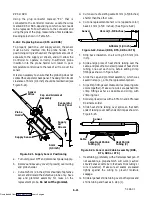

a. Place the sensor (sensing bulb) in a 0

_

C (32

_

F)

ice-water bath. The ice-water bath is prepared by

filling an insulated container (of sufficient size to

completely immerse bulb) with ice cubes or

chipped ice, then filling voids between ice with

water and agitating until mixture reaches 0

_

C

(32

_

F) measured on a laboratory thermometer.

b. Start unit and check air temperature/data readout on

the control panel. The reading should be 0

_

C

(32

_

F); if it is not, continue on to the following step.

c. Turn unit OFF and disconnect power supply.

d. Refer to section 6.27 for removal of the Controller

module.

RTS or STS:

Using the plug connector marked “EC” that is

connected to the Controller module. Locate the wires

marked RTS or STS, depending on which sensor needs

to be replaced. Follow that wire to the connector and

using the pins of the plug, measure the ohms resistance.

Readings are shown in Table 6-5.

Downloaded from