6-24

T-294-01

be in effect. This places the valve at a 21% staging

position and is sufficient to drive the temperature of the

supply probe down several degrees during this interval.

After the CREL time-out has been met, the valve will

start responding to the control logic and open or close,

relative to the demand. Scrutinize the unit operation for

a few minutes. While in pulldown the unit will open the

SMV to a maximum discharge pressure of 350 psig in

high ambient conditions, or as much as the current

setting and control logic will allow. The current level

should be high. A lower discharge pressure will be seen

in lower ambient temperatures. Once the unit has

reached set point, the SMV will go into control mode.

Both the discharge/suction pressures, and current draw

will go significantly lower. Once below set point, the

suction pressure should go into a vacuum within several

minutes. Should the operation differ as mentioned, the

SMV or drive module may be faulty.

4. Attach a manifold gauge set, refer to section 6.1.

Perishable operation:

If the operation of the unit is in question, place the set

point to approximately 6

°

C (11

°

F) less than the current

box temperature, so the unit goes into pulldown. Run

the unit for approximately one minute. Record readings

on gauges and current draw. The current draw and

pressures should go up. Place set point to 0.5

°

C (0.9

°

F)

above current box temperature to fully modulate valve,

and run for approximately one minute.

NOTE

The unit may shut off for a short time. Wait

until the unit self starts and sufficient time has

elapsed to cause the valve to fully modulate.

Record new gauge readings and current draw. The

suction pressure should go into a vacuum and the

current draw should have gone down. If little or no

change to the suction pressure or current draw occurs,

this is an indication of a malfunctioning SMV.

Frozen operation:

In frozen mode the valve will tend to stay open as much

as possible. Again, this is dependent upon current limit

setting and control logic. Turn the unit OFF and ON, as

in the perishable mode, and watch the gauges. The valve

will run at 21% open if CREL logic is active, and will

open to maximum allowable after this. Dependent on

ambient conditions, there should be an increase in

suction pressure and current draw as the valve opens,

however, this may be difficult at times to fully

determine.

5. If the unit still does not operate properly, stop unit,

and check out the SMV system, refer to section

6.24.b.

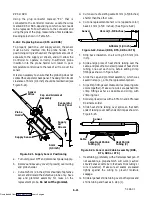

b. Checking the Stepper valve

Disconnect the four pin connector to the stepper SMV.

With a reliable digital ohmmeter, check the winding

resistance. In normal ambient, the valve should have 72

to 84 ohms measured on the red/green (a-b terminals)

and on the white/black (c-d terminals) leads. If an

infinite or zero reading occurs, check connections and

replace the motor. If near normal or normal reading

occurs, refer to section 6.24.e.

c. SMA-12 portable stepper drive tester

The SMA-12 portable stepper drive tester (P/N

07-00375-00) is a battery operated stepper drive which

will allow opening and closing of the SMV, which

allows a more thorough check of the motor.

To check operation:

1. Stop the unit, disconnect the four pin connector

from the stepper module to the valve located on the

suction line near the valve, and attach the SMA-12

stepper drive to the connector going to the valve.

2. Set the SMA-12 pulse per second (PPS) to one PPS

and either open or close valve. Each LED should

light sequentially until all four are lit. Any LED

failing to light indicates an open on that leg which

indicates a poor connection or an open coil. Repair

or replace as required to achieve proper operation.

3. Restart unit, set the step rate to 200 PPS on SMA-12

for the valve, and close stepper valve while

watching the suction gauge. Within one minute the

suction pressure will go into a vacuum. This is an

indication that the valve is moving.

4. If no change in suction pressure is detected, check

for resistance (refer to section 6.24.b.), and check

connections for proper continuity and retest. If the

valve is functioning and all connections and motor

resistance are good, check the drive module. (Refer

to section 6.24.d.)

5. If the valve is determined as faulty after completing

the above steps, perform a high side pump down.

Remove valve powerhead assembly, and replace

with a NEW valve powerhead assembly, torque nut

to 35 ft-lb, evacuate low side, and open all valves.

WARNING

DO NOT disassemble piston from NEW

powerhead assembly! Doing so may result

in damage to piston.

Downloaded from