vii

T--292

LIST OF ILLUSTRATIONS -- Continued

FIGURE NUMBER

Page

Figure 6-11 Water Cooled Condenser Cleaning - Gravity Circulation

6-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-12 Thermostatic Expansion Valve Bulb

6-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-13 Hermetic Thermostatic Expansion Valve Brazing Procedure

6-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-14 Evaporator Expansion Valve

6-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-15 Quench & Economizer Expansion Valves

6-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

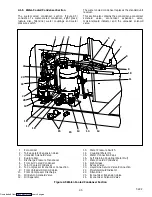

Figure 6-16. Unloader Solenoid Valve

6-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-17. Oil Return Solenoid Valve (ORV) and Economizer Solenoid Valve (ESV)

6-16

. . . . . . . . . . . . . . . . . .

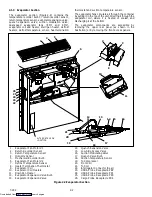

Figure 6-18. Evaporator Fan Assembly

6-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

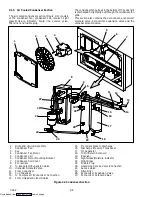

Figure 6-19 Suction Modulation Valve (SMV)

6-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

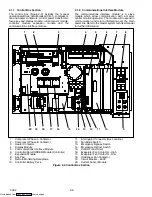

Figure 6-20 Controller Section of the Control Box

6-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-21 Sensor Types

6-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-22 Sensor and Cable Splice

6-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-23 Supply Sensor Positioning

6-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-24 Return Sensor Positioning

6-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-25. Electronic Partlow Temperature Recorder

6-23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-26. Partlow Mechanical Temperature Recorder

6-26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-27. Saginomiya Temperature Recorder

6-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-28 Door Hinge Repair

6-28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-29. Insert Location

6-30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-30. Communications Interface Installation

6-31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7-1 LEGEND

7-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7-2 SCHEMATIC DIAGRAM

7-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7-3 SCHEMATIC DIAGRAM -- Temperature Recorders

7-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7-4 WIRING DIAGRAM, UNITS W/SINGLE CAPACITOR EVAPORATOR FAN MOTORS

7-4

. . . . . . .

Figure 7-5 WIRING DIAGRAM , UNITS W/DUAL CAPACITOR EVAPORATOR FAN MOTORS

7-6

. . . . . . . . .

Figure 7-6 WIRING DIAGRAM -- Electronic Partlow Temperature Recorder

7-8

. . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES

TABLE NUMBER

Page

Table 2-1 Safety and Protective Devices

2-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-1 Key Pad Function

3-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-2 DataCORDER Configuration Variables

3-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-3 DataCORDER Standard Configurations

3-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-4 Controller Configuration Variables

3-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-5 Controller Function Codes

3-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-6 Controller Alarm Indications

3-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-7 Controller Pre-Trip Test Codes

3-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-8 DataCORDER Function Code Assignments

3-25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-9 DataCORDER Pre-Trip Result Records

3-26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-10 DataCORDER Alarm Indications

3-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-1 Compressor Kit

6-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-2 Sensor Temperature/Resistance Chart (+/--.002%)

6-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-3 Temperature-Resistance Chart

6-26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-4 Crack, Chip & Hole Repair Kit

6-30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-5 Insert Repair Kit

6-30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-6 Drill Information

6-30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-7 Recommended Bolt Torque Values

6-32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-8 R-134a Temperature - Pressure Chart

6-33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...