1-2

T-292

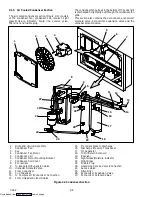

1.3.11 Condenser Coil

The unit may be fitted with a 5 row coil using nominal 3/8

inch tubing, or the unit may be fitted with a 4 row coil

using 7mm tubing. The required refrigerant charge is

different for each coil.

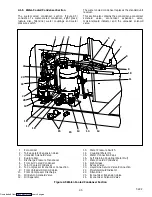

1.3.12 Autotransformer

An autotransformer may be provided to allow operation

on 190/230, 3phase, 50/60 hertz power. The

autotransformer raises the supply voltage to the

nominal 460 volt power required by the base unit. The

autotransformer may also be fitted with an individual

circuit breaker for the 230 volt power.

If the unit is fitted with an autotransformer and

communications module, the autotransformer will be

fitted with a transformer bridge unit (TBU) to assist in

communications.

1.3.13 Temperature Recorder

One of three temperature recording devices may be

fitted to the unit. The devices include a mechanical

recorder manufactured by Partlow Corporation, a

mechanical recorder manufactured by Saginomiya

Corporation, and an electronic recorder manufactured

by Partlow Corporation.

1.3.14 Gutters

Rain gutters may be fitted over the control box and

recorder sections to divert rain away form the controls.

The different gutters include standard length bolted

gutters, extended length gutters and riveted gutters.

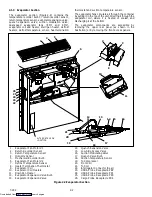

1.3.15 Handles

The unit may be fitted with handles to facilitate access to

stacked containers. These handles may included fixed

handles (located at the sides of the unit) and/or a hinged

handle at the center (attached to the condenser coil

cover).

1.3.16 Thermometer Port

The unit may be fitted with ports in the front of the frame

for insertion of a thermometer to measure supply and/or

return air temperature. If fitted, the port(s) will require a

cap and chain.

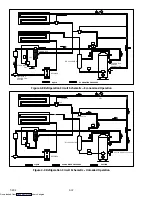

1.3.17 Water Cooling

The refrigeration system may be fitted with a water

cooled condenser. The condenser is constructed using

copper--nickel tube for sea water applications. The

water cooled condenser is in series with the air cooled

condenser replaces the standard unit receiver. When

operating on the water cooled condenser, the

condenser fan is deactivated by either a water pressure

switch or condenser fan switch.

1.3.18 Back Panels

Back panel designs that may be fitted include panels of

aluminum and stainless steel. Panels may be fitted with

access doors and/or hinge mounting.

1.3.19 460 Volt Cable

Various power cable and plug designs are available for

the main 460 volt supply. The plug options tailor the

cables to each customers requirements.

1.3.20 230 Volt Cable

Units equipped with an autotransformer require an

additional power cable for connection to the 230 volt

source. Various power cable and plug designs are

available. The plug options tailor the cables to each

customers requirements.

1.3.21 Cable Restraint

Various designs are available for storage of the power

cables. These options are variations of the compressor

section front cover.

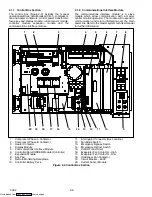

1.3.22 Upper Air (Fresh Air Make Up)

The unit may be fitted with an upper fresh air makeup

assembly. The fresh air makeup assembly is available

with a Vent Positioning Sensor (VPS) and may also be

fitted with screens.

1.3.23 Lower Air (Fresh Air Make Up)

The unit may be fitted with a lower fresh air makeup

assembly. The assembly may also be fitted with

screens.

1.3.24 Controlled Atmosphere

The unit may be fitted with the TransFRESH option.

For information on the TransFRESH system, contact

TransFRESH Corporation, P.O. Box 1788, Salinas CA

93902

1.3.25 Power Correction

The unit may be fitted with a set of power factor

correction capacitors to assist in correction of

imbalance in current draw by the compressor.

1.3.26 Evaporator

The unit is fitted with an evaporator coil and a hermetic

thermal expansion valve.

1.3.27 Evaporator Fan Operation

The units are fitted with Normal Evaporator Fan

Operation, opening of an evaporator fan internal

protector will shut down the unit.

1.3.28 Labels

Operating Instruction and Function Code listing labels

will differ depending on the options installed. For

example, additional operating instructions are required

to describe start--up of a unit equipped with an

autotransformer. Where the labels are available with

additional languages, they are listed in the parts list.

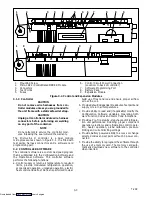

1.3.29 Emergency Bypass

The unit may be equipped with switches to allow

emergency

bypass

of

the

controller.

The

EMERGENCY BYPASS switch functions to bypass

the controller in the event of controller failure. The

EMERGENCY DEFROST switch functions to bypass

all controls and place the unit in the defrost mode.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

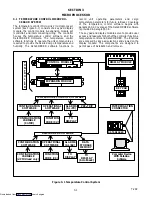

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...