2-10

T-292

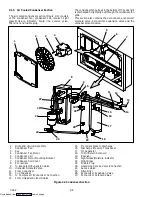

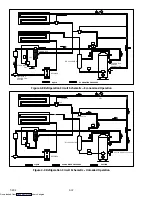

2.5 REFRIGERATION CIRCUIT

2.5.1 Standard Operation

Starting at the compressor, (see Figure 2-7, upper

schematic) the suction gas is compressed to a higher

pressure and temperature.

In the standard mode, both the economizer and

unloader solenoid valves are closed. The gas flows

through the discharge line into the oil separator. In the

separator, oil is removed from the refrigerant and stored

for return to the compressor when the oil return solenoid

valve is opened by the controller. The oil return solenoid

valve is a normally open valve which allows return of oil

during the off cycle.

The refrigerant gas continues into the air-cooled

condenser. When operating with the air-cooled

condenser active, air flowing across the coil fins and

tubes cools the gas to saturation temperature. By

removing latent heat, the gas condenses to a high

pressure/high temperature liquid and flows to the

receiver which stores the additional charge necessary

for low temperature operation.

When operating with the water cooled condenser active

(see Figure 2-7, lower schematic), the refrigerant gas

passes through the air cooled condenser and enters the

water cooled condenser shell. The water flowing inside

the tubing cools the gas to saturation temperature in the

same manner as the air passing over the air cooled

condenser. The refrigerant condenses on the outside of

the tubes and exits as a high temperature liquid. The

water cooled condenser also acts as a receiver, storing

excess refrigerant.

The liquid refrigerant continues through the liquid line,

the filter-drier (which keeps refrigerant clean and dry)

and the economizer (which is not active during standard

operation) to the evaporator expansion valve. As the

liquid refrigerant passes through the variable orifice of

the expansion valve, some of it vaporizes into a gas

(flash gas). Heat is absorbed from the return air by the

balance of the liquid, causing it to vaporize in the

evaporator coil. The vapor then flows through the

suction modulation valve to the compressor.

The evaporator expansion valve is activated by the bulb

strapped to the suction line near the evaporator outlet.

The valve maintains a constant superheat at the coil

outlet regardless of load conditions.

On systems fitted with a water pressure switch, the

condenser fan will be off when there is sufficient

pressure to open the switch. If water pressure drops

below the switch cut out setting, the condenser fan will

be automatically started. When operating a system

fitted with a condenser fan switch, the condenser fan will

be off when the switch is placed in the “O” position. The

condenser fan will be on when the switch is placed in the

“I” position.

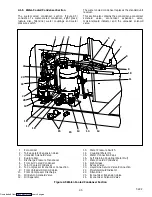

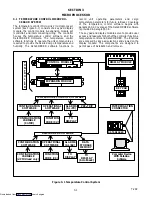

2.5.2 Economized Operation

In the economized mode the frozen and pull down

capacity of the unit is increased by subcooling the liquid

refrigerant entering the evaporator expansion valve.

Overall efficiency is increased because the gas leaving

the economizer enters the compressor at a higher

pressure, therefore requiring less energy to compress it

to the required condensing conditions.

During economized operation, flow of refrigerant

through the main refrigerant system is identical to the

standard mode. (The unloader solenoid valve is

de--energized [closed] by the controller.)

Liquid refrigerant for use in the economizer circuit is

taken from the main liquid line as it leaves the filter--drier

(see Figure 2-8). The flow is activated when the

controller energizes the economizer solenoid valve. The

liquid refrigerant flows through the economizer

expansion valve and the economizer internal passages

absorbing heat from the liquid refrigerant flowing to the

evaporator expansion valve. The resultant “medium”

temperature/pressure gas enters the compressor at the

economizer line.

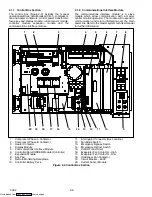

2.5.3 Unloaded Operation

The system will operate in the unloaded mode; during

periods of low load, during periods of required discharge

pressure or current limiting, and during start--up.

During unloaded operation, flow of refrigerant through

the main refrigerant system is identical to the standard

mode. (The economizer solenoid valve is de--energized

[closed] by the controller.)

In the unloaded mode, a portion of the mid--stage

compressed gas is bypassed to decrease compressor

capacity. The flow is activated when the controller opens

the unloader solenoid valve (see Figure 2-9). Opening

of the valve creates a bypass from the economizer

service valve through the unloader solenoid valve and

into the suction line on the outlet side of the suction

pressure modulation valve.

As load on the system decreases, the suction

modulating valve decreases flow of refrigerant to the

compressor. This action balances the compressor

capacity with the load and prevents operation with low

coil temperatures. In this mode of operation, the quench

valve will open as required to provide sufficient liquid

refrigerant flow into the suction line for cooling of the

compressor motor. The quench valve senses

refrigerant condition entering the compressor and

modulates the flow to prevent entrance of liquid into the

compressor.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...