3-4

T-292

3.2.1 Configuration Software (Configuration Vari-

ables)

The Configuration Software is a variable listing of the

components available for use by the Operational

Software. This software is factory installed in

accordance with the equipment fitted and options listed

on the original purchase order. Changes to the

Configuration Software are required only when a new

controller has been installed or a physical change has

been made to the unit such as the addition or removal of

an option. A Configuration Variable list is provided in

Table 3-4. Change to the factory installed Configuration

Software is achieved via a configuration card or by

communications.

3.2.2 Operational Software (Function codes)

The Operational Software is the actual operation

programming of the controller which activates or

deactivates components in accordance with current unit

operating conditions and operator selected modes of

operation.

The programming is divided into function Codes. Some

of the codes are read only while the remaining codes

may be user configured. The value of the user

configurable codes can be assigned in accordance with

user desired mode of operation. A list of the function

codes is provided in Table 3-5.

To access the function codes, perform the following:

a. Press the CODE SELECT key, then press an arrow

key until the left window displays the desired code

number.

b. The right window will display the value of this item for

five seconds before returning to the normal display

mode.

c. If a longer time is desired, press the ENTER key to

extend the time to 30 seconds.

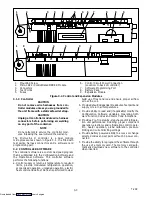

3.3 MODES OF OPERATION

The Operational Software responds to various inputs.

These inputs come from the temperature and pressure

sensors, the temperature set point, the settings of the

the configuration variables and the function code

assignments. The action taken by the Operational

Software will change if any one of the inputs changes.

Overall interaction of the inputs is described as a “mode”

of operation. The modes of operation include,

perishable (chill) mode and frozen mode. Descriptions

of the controller interaction and modes of operation are

provided in the following sub paragraphs.

3.3.1 Temperature Control -- Perishable Mode

With configuration variable CnF26 (Heat Lockout

Temperature) set to --10

_

C the perishable mode of

operation is active with set points

above --10

_

C (+14

_

F).

With the variable set to --5

_

C, the perishable mode is

active

below --5

_

C (+23

_

F

). Refer to Table 3-4.

When in the perishable mode the controller maintains

the supply air temperature at set point, the SUPPLY

indicator light will be illuminated on the display module

and the default reading on the display window will be the

supply temperature sensor reading.

When the supply air temperature enters the in-range

temperature tolerance (as selected at function code

Cd30), the in-range light will energize.

3.3.2 Defrost Interval

Function code Cd27 may be operator set to initiate

defrost at intervals of 3, 6, 9, 12 or 24 hours. It may also

be set to OFF (no defrost). The factory default is 12

hours. Refer to Table 3-5.

3.3.3 Failure Action

Function code Cd29 may be operator set to allow

continued operation in the event that all of the control

sensors are reading out of range. The factory default is

full system shutdown. Refer to Table 3-5.

3.3.4 Generator Protection

Function codes Cd31(Stagger Start, Offset Time) and

Cd32 (Current Limit) may be operator set to control start

up sequence of multiple units and operating current

draw. The factory default allows on demand starting (no

delay) of units and normal current draw. Refer to

Table 3-5.

3.3.5 Compressor High Temperature, Low Pres-

sure Protection.

The controller monitors compressor discharge

temperature and suction pressure. If discharge

pressure rises above the allowed limit or suction

pressure falls below the allowed limit the compressor

will be cycled off on a three minute timer. Condenser and

evaporator fans continue to operate during the

compressor off cycle.

3.3.6 Perishable Mode -- Conventional

The unit is capable of maintaining supply air

temperature to within

¦

0.25

_

C (

¦

0.5

_

F) of set point.

Supply air temperature is controlled by positioning of the

suction modulation valve (SMV), cycling of the

compressor and cycling of the heaters.

When cooling from a temperature that is more than

2.5

_

C (4.5

_

F) above set point, the system will be in the

perishable pull down mode. It will be in economized

operation with a target SMV position of 100% open.

However, pressure and current limit functions may

restrict the valve, if either exceeds the preset value.

Once set point is reached, the unit will transition to the

perishable steady state mode. This results in unloaded

operation with some restriction of the SMV. The SMV

will continue to close and restrict refrigerant flow until the

capacity of the unit and the load are balanced.

If the SMV is at minimum modulation, the controller has

determined that cooling is not required, or the controller

logic determines suction pressure is at the low pressure

limit, the unit will transition to the perishable idle mode.

The compressor is turned off and the evaporator fans

continue to run to circulate air throughout the container.

If temperature rises above set point +0.2

_

C, the unit will

transition back to the perishable steady state mode

If the temperature drops to 0.5

_

C (0.9

_

F) below set

point, the unit will transition to the perishable heating

mode and the heaters will be energized . The unit will

transition back to the perishable idle mode when the

temperature rises to 0.2

_

C (0.4

_

F) below the set point

and the heaters will de-energize

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...