3-8

T-292

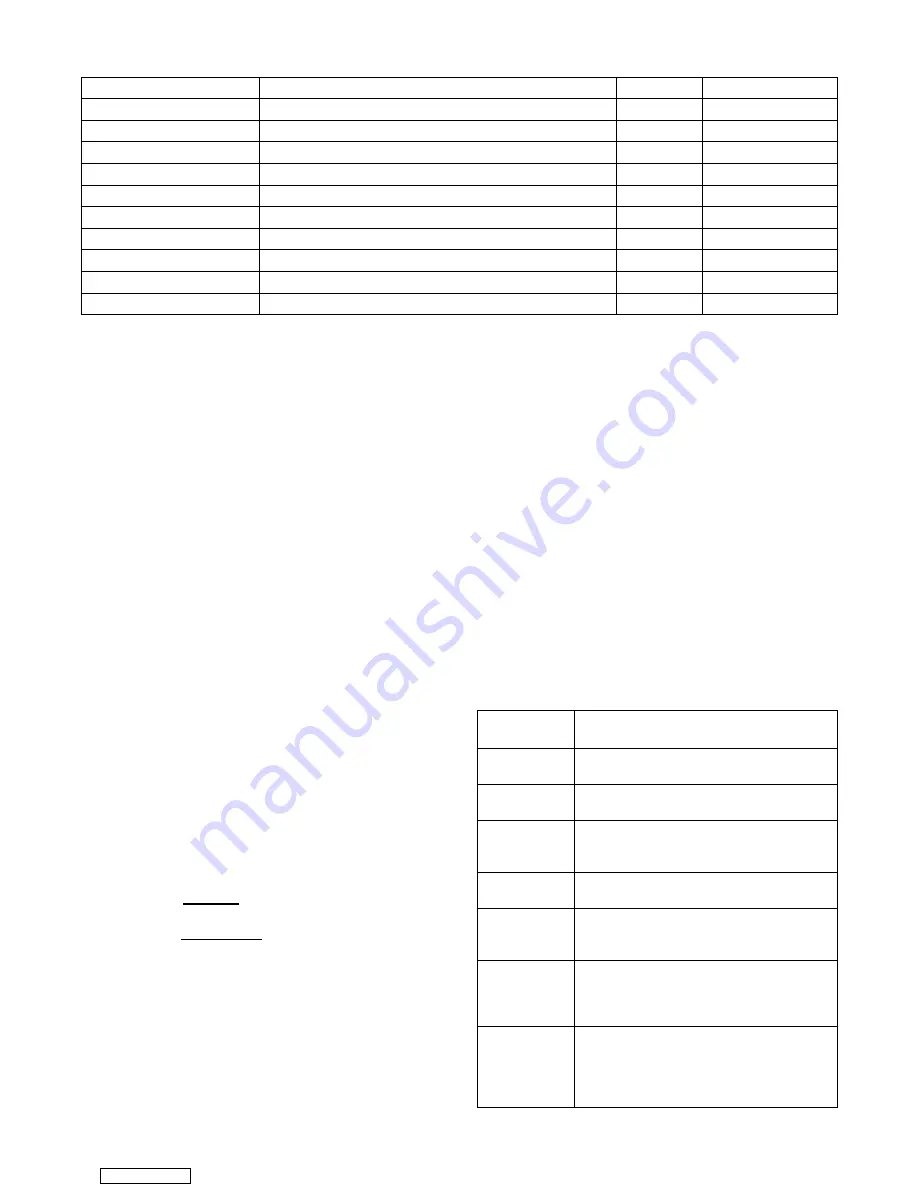

Table 3-2 DataCORDER Configuration Variables

CONFIGURATION NO.

TITLE

DEFAULT

OPTION

dCF01

(Future Use)

----

----

dCF02

Sensor Configuration

2

2,5,6,9,54,64,94

dCF03

Logging Interval (Minutes)

60

15,30,60,120

dCF04

Thermistor Format

Short

Long

dCF05

Thermistor Sampling Type

A

A,b,C

dCF06

Controlled Atmosphere/Humidity Sampling Type

A

A,b

dCF07

Alarm Configuration USDA Sensor 1

A

Auto, On, Off

dCF08

Alarm Configuration USDA Sensor 2

A

Auto, On, Off

dCF09

Alarm Configuration USDA Sensor 3

A

Auto, On, Off

dCF10

Alarm Configuration Cargo Sensor

A

Auto, On, Off

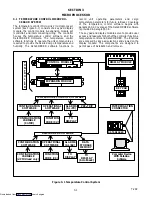

b. Configuration Software

The configuration software controls the recording and

alarm functions of the DataCORDER. Reprogramming

to the factory installed configuration is achieved via a

configuration card. Changes to the unit DataCORDER

configuration may be made made using the

DataView/DataLine interrogation software. A listing of

the configuration variables is provided in Table 3-2.

Descriptions of DataCORDER operation for each

variable setting are provided in the following

paragraphs.

3.6.3 Sensor Configuration (dCF02)

Two modes of operation may be configured, the

Standard Mode and the Generic Mode.

a. Standard Mode

In the standard mode, the user may configure the

DataCORDER to record data using one of seven

standard

configurations.

The

seven

standard

configuration variables, with their descriptions, are

listed in Table 3-3.

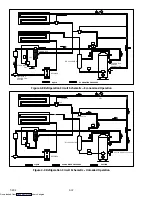

The inputs of the six thermistors (supply, return, USDA

#1, #2, #3 and cargo probe) and the humidity sensor

input will be generated by the DataCORDER. See

Figure 3- 5.

NOTE

The DataCORDER software uses the supply

and return recorder sensors (SRS,RRS). The

temperature control software uses the supply

and return temperature sensors (STS,RTS) .

b. Generic Mode

The generic recording mode allows user selection of the

network data points to be recorded. The user may select

up to a total of eight data points for recording. A list of the

data points available for recording follows. Changing the

configuration to generic and selecting which data points

to record may be done using the Carrier Transicold Data

Retrieval Program.

1. Control mode

2. Control temperature

3. Frequency

4. Humidity

5. Phase A current

6. Phase B current

7. Phase C current

8. Main voltage

9. Suction modulation valve percentage

10. Discrete outputs (Bit mapped -- require special

handling if used)

11. Discrete inputs (Bit mapped -- require special

handling if used)

12. Ambient sensor

13. Compressor suction sensor

14. Compressor discharge sensor

15. Return temperature sensor (RTS)

16. Supply temperature sensor (STS)

17. Defrost temperature sensor

18. Discharge pressure transducer

19. Suction pressure transducer

20. Condenser pressure transducer

21. Vent position sensor (VPS)

Table 3-3 DataCORDER Standard Configurations

Standard

Config.

Description

2 sensors

(dCF02=2)

2 thermistor inputs(supply & return)

5 sensors

(dCF02=5)

2 thermistor inputs(supply & return)

3 USDA thermistor inputs

6 sensors

(dCF02=6)

2 thermistor inputs(supply & return)

3 USDA thermistor inputs

1 humidity input

9 sensors

(dCF02=9)

Not Applicable

6 sensors

(dCF02=54)

2 thermistor inputs(supply & return)

3 USDA thermistor inputs

1 cargo probe (thermistor input)

7 sensors

(dCF02=64)

2 thermistor inputs(supply & return)

3 USDA thermistor inputs

1 humidity input

1 cargo probe (thermistor input)

10 sensors

(dCF02=94

)

2 thermistor inputs(supply & return)

3 USDA thermistor inputs

1 humidity input

1 cargo probe (thermistor input)

3 C.A. inputs (NOT APPLICABLE)

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...