3-11

T-292

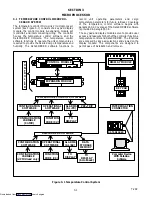

b. DataView

The DataView software for a personal computer is

supplied on a floppy disk. This software allows

interrogation, configuration variable assignment,

screen view of the data, hard copy report generation,

cold treatment probe calibration, cold treatment

initialization and file management. Refer to Data

Retrieval manual 62-02575 for a more detailed

explanation of the DataView interrogation software.

c. Communications Interface Module

The communications interface module is a slave

module which allows communication with a master

central monitoring station. The module will respond to

communication and return information over the main

power line.

With a remote monitoring unit installed, all functions and

selectable features that are accessible at the unit may

be performed at the master station. Retrieval of all

DataCORDER reports may also be performed. Refer to

the master system technical manual for further

information.

d. DataLine

The DataLINE software for a personal computer is

supplied on both floppy disks and CD. This software

allows interrogation, configuration variable assignment,

screen view of the data, hard copy report generation,

cold treatment probe calibration and file management.

Refer to Data Retrieval manual 62-10629 for a more

detailed explanation of the DataLINE interrogation

software. The DataLine manual may be found on the net

at www.contaner.carrier.com

3.6.11 USDA Cold Treatment

Sustained cold temperature has been employed as an

effective postharvest method for the control of

Mediterranean and certain other tropical fruit flies.

Exposing infested fruit to temperatures of 2.2 degrees

Celsius (36

_

F) or below for specific periods results in

the mortality of the various stages of this group of

insects.

In response to the demand to replace fumigation with

this environmentally sound process, Carrier has

integrated

Cold

Treatment

capability

into its

microprocessor system. These units have the ability to

maintain supply air temperature within one-quarter

degree Celsius of setpoint and record minute changes

in product temperature within the DataCORDER

memory, thus meeting USDA criteria. Information on

USDA is provided in the following subparagraphs

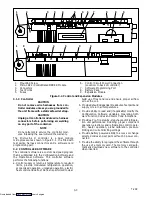

a. USDA Recording

A special type of recording is used for USDA cold

treatment purposes. Cold treatment recording requires

three remote temperature probes be placed at

prescribed locations in the cargo. Provision is made to

connect these probes to the DataCORDER via

receptacles located at the rear left-hand side of the unit.

Four or five receptacles are provided. The four three-pin

receptacles are for the probes. The five pin receptacle is

the rear connection for the Interrogator. The probe

receptacles are sized to accept plugs with tricam

coupling locking devices. A label on the back panel of

the unit shows which receptacle is used for each probe.

The standard DataCORDER report displays the supply

and return air temperatures. The cold treatment report

displays USDA #1, #2, #3 and the supply and return air

temperatures. Cold treatment recording is backed up by

a battery so recording can continue if AC power is lost.

b. USDA/ Message Trip Comment

A special feature is incorporated in DataLine/DataView

which allows the user to enter a USDA (or other)

message in the header of a data report. The maximum

message length is 78 characters. Only one message will

be recorded per day.

3.6.12 USDA Cold Treatment Procedure

The following is a summary of the steps required to

initiate a USDA Cold Treatment.

a. Calibrate the three USDA probes by ice bathing the

probes and performing the calibration function with

the DataReader, DataView or DataLine. This calibra-

tion procedure determines the probe offsets and

stores them in the controller for use in generating the

cold treatment report. Refer to the Data Retrieval

manual 62-02575 for more details.

b. Pre-cool the container to the treatment temperature

or below.

c..

Install the DataCORDER module battery

pack (if not already installed).

d. Place the three probes. The probes are placed into

the pulp of the product (at the locations defined in the

following table) as the product is loaded.

Sensor 1 Place in pulp of the product located next

to the return air intake.

Sensor 2

Place in pulp of the product five feet

from the end of the load for 40 foot con-

tainers, or three feet from the end of the

load for 20 foot containers. This probe

should be placed in a center carton at

one-half the height of the load.

Sensor 3

Place in pulp of product five feet from

the end of the load for 40 foot containers

or three feet from the end of the load for

20 foot containers. This probe should be

placed in a carton at a side wall at one-

half the height of the load.

e. To initiate USDA Recording, connect the personal

computer and perform the configuration as follows,

using either the Data View or Data Line software:

1. Enter ISO header information

2. Enter a trip comment if desired

3. Configure the DataCORDER for five probes (s, r, P1,

P2, P3) (dcf02=5)

4. Configure the logging interval for one hour.

5. Set the sensor configuration to “USDA”.

6. Configure for two byte memory storage format

(dcf04=LONG).

7. Perform a “trip start”

3.6.13 DataCORDER Alarms

The alarm display is an independent DataCORDER

function. If an operating parameter is outside of the

expected range or a component does not return the

correct values back to the DataCORDER an alarm is

generated. The DataCORDER contains a buffer of up to

eight alarms. A listing of the DataCORDER alarms is

provided in Table 3-10, page 3-26. Refer to paragraph

3.6.7 for configuration information.

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...