T-292

4-2

Units may be equipped with a Vent Position Sensor

(VPS). The VPS determines the position of the fresh air

vent and sends data to the controller display.

0

30

60

90

120

150

180

210

240

0

10 20 30 40 50 60 70 80 90 100

AIR

FLOW

(CMH)

1-

!

/

2

”

PERCENT OPEN

50HZ

T-BAR

2-

%

/

8

”

3”

T-BAR

T-BAR

0

40

80

120

160

200

240

280

0 10 20 30 40 50 60 70 80 90 100

AIR

FLOW

(CMH)

1-

!

/

2

”

PERCENT OPEN

T-BAR

2-

%

/

8

”

3”

T-BAR

T-BAR

60HZ

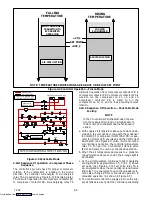

Figure 4-2 Make Up Air Flow Chart

4.3.2 Lower Fresh Air Makeup Vent

a. Full Open or Closed Positions

Maximum air flow is achieved by loosening the wing

nuts and moving the cover to the maximum open

position (100% position). The closed position is 0% air

flow position.The operator may also adjust the opening

to increase or decrease the air flow volume to meet the

required air flow.

b. Reduced Flow for Fresh Air Makeup

On some models the air slide is supplied with two

adjustable air control disks. The fresh air makeup can be

adjusted for (15, 35, 50 or 75) cubic meters per hour

(CMH). The air flow has been established at 60HZ

power and 2 1/2 inch T bar and with 15mm (.6 inch) H2O

external static above free blow.

Loosen the hex nut and adjust each disk to the required

air flow and tighten hex nut.

NOTE

The main air slide is in the fully closed position

during reduced air flow operation.

NOTE

Model 69NT40-454 has a special air makeup

cover with a maximum air flow (100% open) of

80CMH (47CFM).

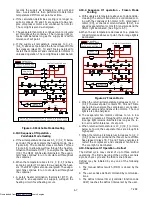

c. Adjustment

The air slide is supplied with two adjustable air control

discs. The fresh air makeup can be adjusted for 15, 35,

50 and 75 cubic meters per hour (CFM). The air flow has

been established at 60 Hz power, and a 2 1/2 inch T bar,

with 15 mm (0.6 inch) H

2

O external static above free

blow.

NOTE

The main air slide is in the fully closed position

during reduced air flow operation.

d. Air Sampling for Carbon Dioxide (CO

2

) Level

Loosen hex nuts and move the cover until the arrow on

the cover is aligned with the “atmosphere sampling port”

label. Tighten the hex nuts and attach a 3/8 hose to the

sampling port.

If the internal atmosphere content has reached an

unacceptable level, the operator may adjust the disc

opening to meet the required air flow volume to ventilate

the container.

4.4 CONNECT WATER-COOLED CONDENSER

The water-cooled condenser is used when cooling

water is available and heating the surrounding air is

objectionable, such as in a ship’s hold. If water cooled

operation is desired, connect in accordance with the

following subparagraphs.

4.4.1 Water--Cooled Condenser with Water Pres-

sure Switch

a. Connect the water supply line to the inlet side of con-

denser and the discharge line to the outlet side of the

condenser. (See Figure 2-5.)

b. Maintain a flow rate of 11 to 26 liters per minute (3 to 7

gallons per minute). The water pressure switch will

open to de-energize the condenser fan relay. The

condenser fan motor will stop and will remain stopped

until the water pressure switch closes.

c. To shift to air-cooled condenser operation,disconnect

the water supply and the discharge line to the water-

cooled condenser. The refrigeration unit will shift to

air-cooled condenser operation when the water pres-

sure switch closes.

4.4.2 Water-Cooled Condenser with Condenser

Fan Switch

a. Connect the water supply line to the inlet side of con-

denser and the discharge line to the outlet side of the

condenser. (See Figure 2-5.)

b. Maintain a flow rate of 11 to 26 lpm (3 to 7 gpm).

c. Set the condenser fan switch to position ”O”. This will

de-energize the condenser fan relay. The condenser

Downloaded from

Summary of Contents for 69NT40-531 Series

Page 2: ...Downloaded from ManualsNet com search engine ...

Page 4: ...Downloaded from ManualsNet com search engine ...

Page 8: ...Downloaded from ManualsNet com search engine ...

Page 16: ...Downloaded from ManualsNet com search engine ...

Page 57: ...Downloaded from ManualsNet com search engine ...

Page 104: ...Downloaded from ManualsNet com search engine ...

Page 106: ...7 2 T 292 Figure 7 2 SCHEMATIC DIAGRAM Downloaded from ManualsNet com search engine ...